Preparation method of prednisolone sodium phosphate intermediate

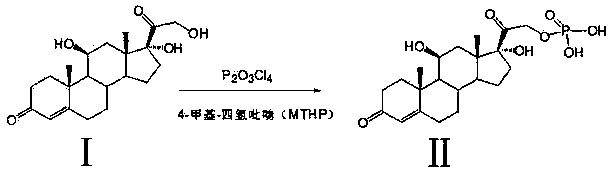

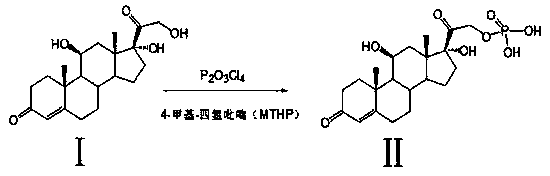

A technology for prednisolone sodium phosphate and prednisolone phosphate, which is applied in the preparation of pharmaceutical intermediates and the preparation field of prednisolone sodium phosphate intermediate prednisolone phosphate, can solve the problem of unfavorable quality of raw materials. , does not meet the problems of energy saving and environmental protection, serious environmental pollution, etc., to achieve the effect of more secure quality yield, avoid impurities, and reduce side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A. In the reaction bottle, add 50g of prednisolone and 500ml of MTHP under the protection of nitrogen, stir and cool down to -55~-60℃, slowly add 40ml of pyrophosphoryl chloride dropwise within 40min, after the addition is completed, keep warm for 1h, and detect by TLC No raw material points;

[0018] B. Add 100ml of purified water to quench the reaction, let it stand for 2 hours, and separate the layers;

[0019] C. The organic phase was extracted twice with 150ml of purified water each time, and then 2.5g of activated carbon was added to the organic phase for decolorization at 30°C for 1 hour;

[0020] D. Filter, concentrate under reduced pressure at 60°C to a paste, cool to below 0°C and discharge, vacuum-dry at 60°C to constant weight, HPLC99.5%, maximum simplex 0.2%, yield 115.2%.

Embodiment 2

[0022] A. In the reaction bottle, add 100g of prednisolone and 1000ml of MTHP under the protection of nitrogen, stir and cool down to -55~-60℃, slowly add 80ml of pyrophosphoryl chloride dropwise within 1 hour, after the addition is completed, keep it warm for 80min, and detect it by TLC No raw material points;

[0023] B. Add 200ml of purified water to quench the reaction, let it stand for 3 hours, and separate the layers;

[0024] C. The organic phase was extracted twice with 300ml of purified water each time, and then 5g of activated carbon was added to the organic phase for decolorization at 40°C for 1.5h;

[0025] D. Filtrate, concentrate under reduced pressure at 60°C to a paste, cool to below 0°C and discharge, vacuum-dry at 70°C to constant weight, HPLC99.4%, maximum simplex 0.25%, yield 116.3%, of which MTHP800ml was recovered.

Embodiment 3

[0027] A. In the reaction bottle, add 50g of prednisolone under the protection of nitrogen, recover 500ml of MTHP, stir and lower the temperature to -55~-60℃, slowly add 50ml of pyrophosphoryl chloride dropwise within 45min, after the addition is completed, keep warm for 1h, TLC Detect no raw material point;

[0028] B. Add 75ml of purified water to quench the reaction, let it stand for 3 hours, and separate the layers;

[0029] C. The organic phase was extracted twice with 200ml of purified water each time, and then 3g of activated carbon was added to the organic phase for decolorization at 40°C for 1.5h;

[0030] D. Filtrate, concentrate under reduced pressure at 60°C to a paste, cool to below 0°C and discharge, vacuum-dry at 60°C to constant weight, HPLC99.5%, maximum simplex 0.21%, yield 116.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com