Flame retardant, preparation method and application thereof

A technology of flame retardant and aliphatic alkyl, which is applied in the field of flame retardant and its preparation, can solve the problems of reducing the ionic conductivity of the electrolyte, battery reversibility, and large damage to the graphite negative electrode, and achieves obvious flame retardant effect and high conductivity. The effect of small influence and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

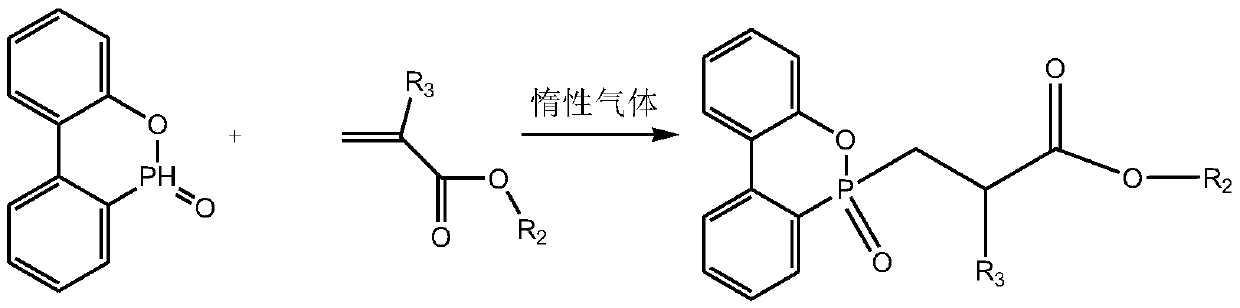

[0028] The present invention also provides the preparation method of above-mentioned flame retardant, and this preparation method comprises the following steps:

[0029] 1) At a certain reaction temperature, DOPO is added to olefin ester monomers to obtain a mixed solution containing white precipitate;

[0030] 2) After the mixed solution in step 1) is suction filtered, the solid is collected and vacuum-dried;

[0031] The reaction formula of step 1) is as follows:

[0032]

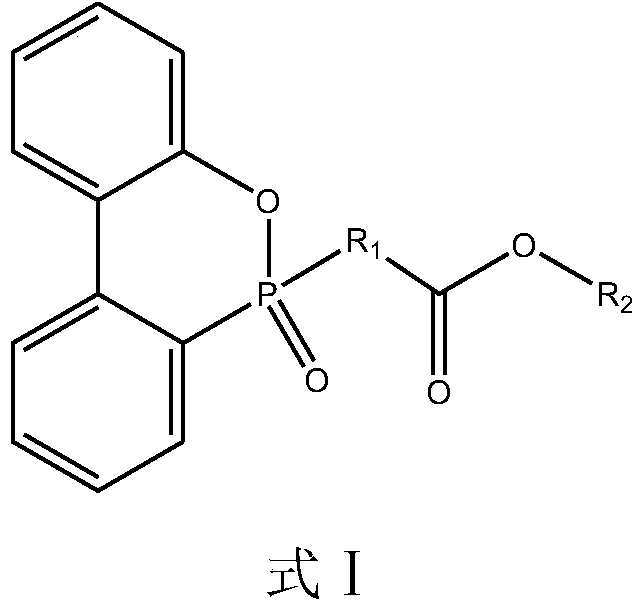

[0033] Among them, R 2 for C 1 -C 4 One or more combinations of aliphatic alkyl, alkenyl, and carboxylic acid groups; R 3 selected from hydrogen, C 1 -C 4 One or more combination of aliphatic alkyl group, alkenyl group, carboxylic acid group, and carboxylate group.

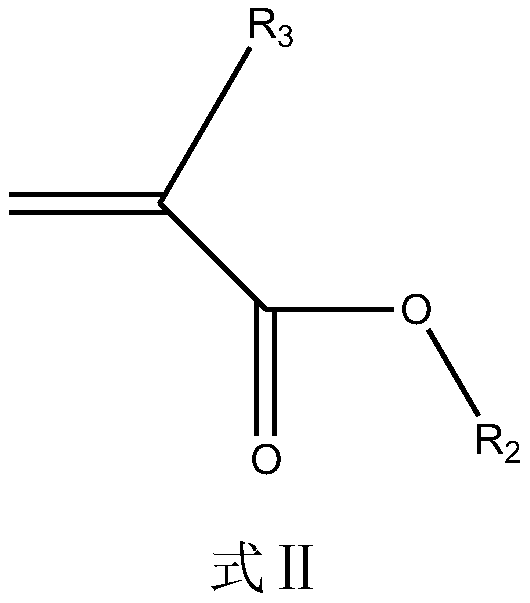

[0034] Preferably, the olefin ester monomer is an unsaturated carboxylic acid ester, and its general structural formula is shown in Formula II:

[0035]

[0036] Preferably, the reaction temperature of the above preparation meth...

Embodiment 1

[0049] (1) Preparation of Flame Retardant (I)

[0050] in N 2 Under the protection of , add 54g DOPO and 30g methyl methacrylate into a three-necked flask, and react for 3-5h at a reaction temperature of 140°C. After the temperature is lowered to room temperature, a white solid (I) is obtained, and excess methyl methacrylate is removed by filtration. methyl acrylate to obtain compound (I), ie flame retardant (I); the compound (I) has a purity of 99% and a yield of 92.3%. The structural formula of compound (I) is shown in formula III:

[0051]

[0052] (2) Preparation of positive pole piece

[0053] Mix lithium nickel cobalt aluminate, acetylene black, and polyvinylidene fluoride according to the mass ratio of 96:2:2, add N-methylpyrrolidone, and stir the mixture at high speed to obtain a uniform positive electrode slurry and coat it on an aluminum foil After drying, the positive electrode sheet is obtained.

[0054] (3) Preparation of negative pole piece

[0055] Mix g...

Embodiment 2

[0061] (1) Preparation of Flame Retardant (II)

[0062] Under the protection of N2, add 54g DOPO and 34g perfluoroalkyl ethyl acrylate into a three-necked flask, react at a reaction temperature of 150°C for 5-6h, and after the temperature is lowered to room temperature, a white solid (II) is obtained, which is filtered Excess perfluoroalkyl ethyl acrylate was removed to obtain compound (II), ie flame retardant (II); compound (II) had a purity of 98.5% and a yield of 91.2%. The structural formula of compound (II) is shown in formula IV:

[0063]

[0064] (2) and (3) The positive pole piece and the negative pole piece are the same as those in Embodiment 1, and will not be repeated here.

[0065] (4) Preparation of electrolyte solution (II)

[0066] Add non-aqueous organic solvent (non-aqueous organic solvent according to ethylene carbonate (EC): dimethyl carbonate (DMC): ethyl methyl carbonate (EMC): propylene carbonate (PC) = 3:4:2:1 mass ratio mixed evenly), lithium salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com