Comprehensive steel slag utilization method

A technology for steel slag and steel slag sand, which is applied in the field of comprehensive utilization of steel slag, can solve problems such as low utilization efficiency of steel slag, and achieve the effects of improving air separation efficiency, improving efficiency and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

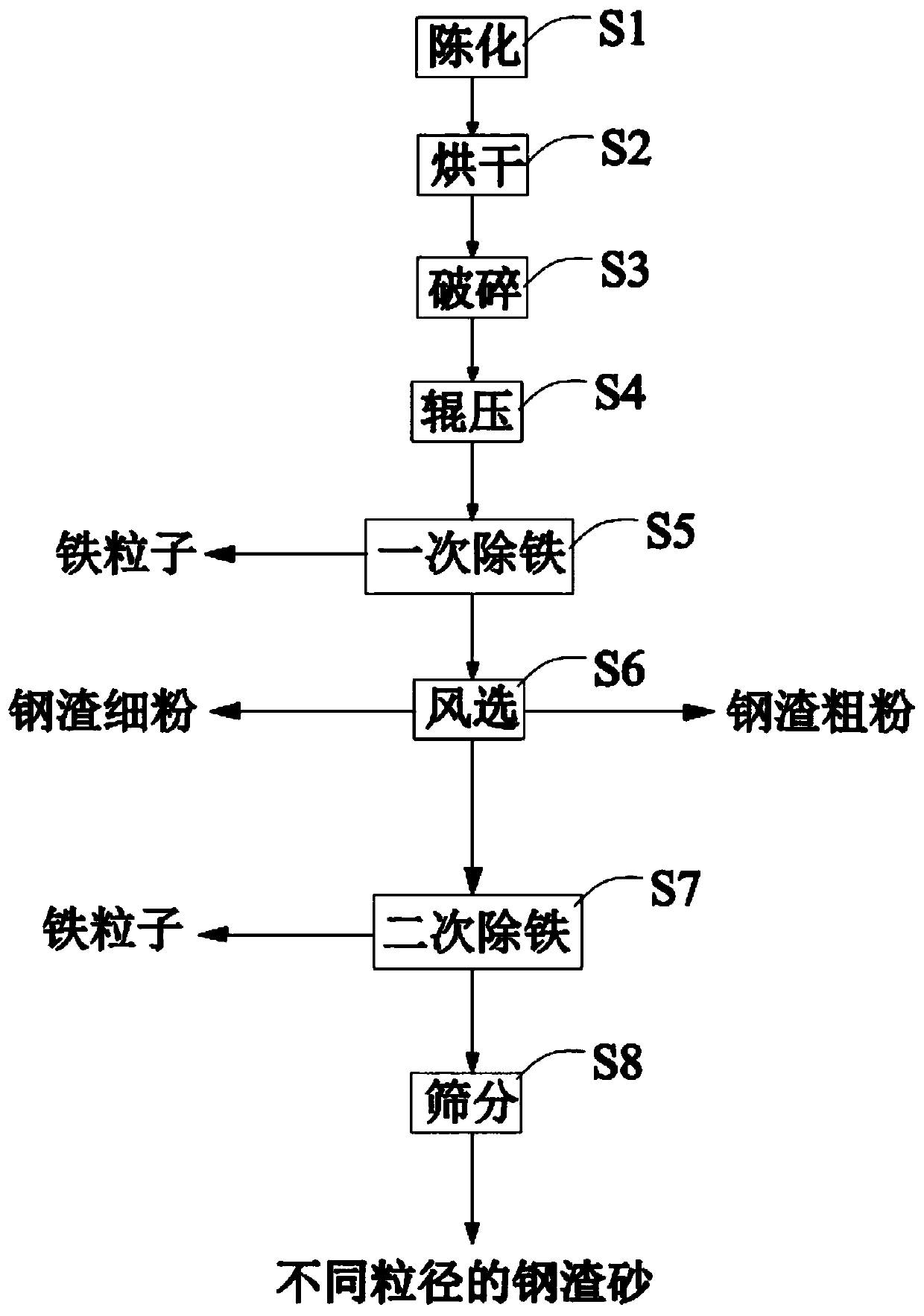

[0055] refer to figure 1 , the comprehensive utilization method of steel slag in the present embodiment, comprises the steps:

[0056] S1. Aging: Stack the steel slag produced in the steelmaking process for more than 3 months in the natural environment to obtain aged steel slag; the chemical properties of the aged steel slag are more stable and the moisture content is also reduced;

[0057] Before the step S1, it also includes: regularly checking the chemical composition and physical properties of the steel slag, such as moisture content;

[0058] S2. Drying: Send the aged steel slag obtained in step S1 into a rotary dryer for drying treatment to obtain dried steel slag; wherein, the drying temperature in the drying process is 700°C , the moisture content of the dried steel slag is below 1%;

[0059] S3, crushing: crushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com