Basketball stand backboard surface grinding device

A technology for basketball racks and backboards, which is applied to grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve the problems of low grinding efficiency, inability to efficiently grind backboards, and limited grinding range, so as to achieve comprehensive grinding and promote grinding. effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

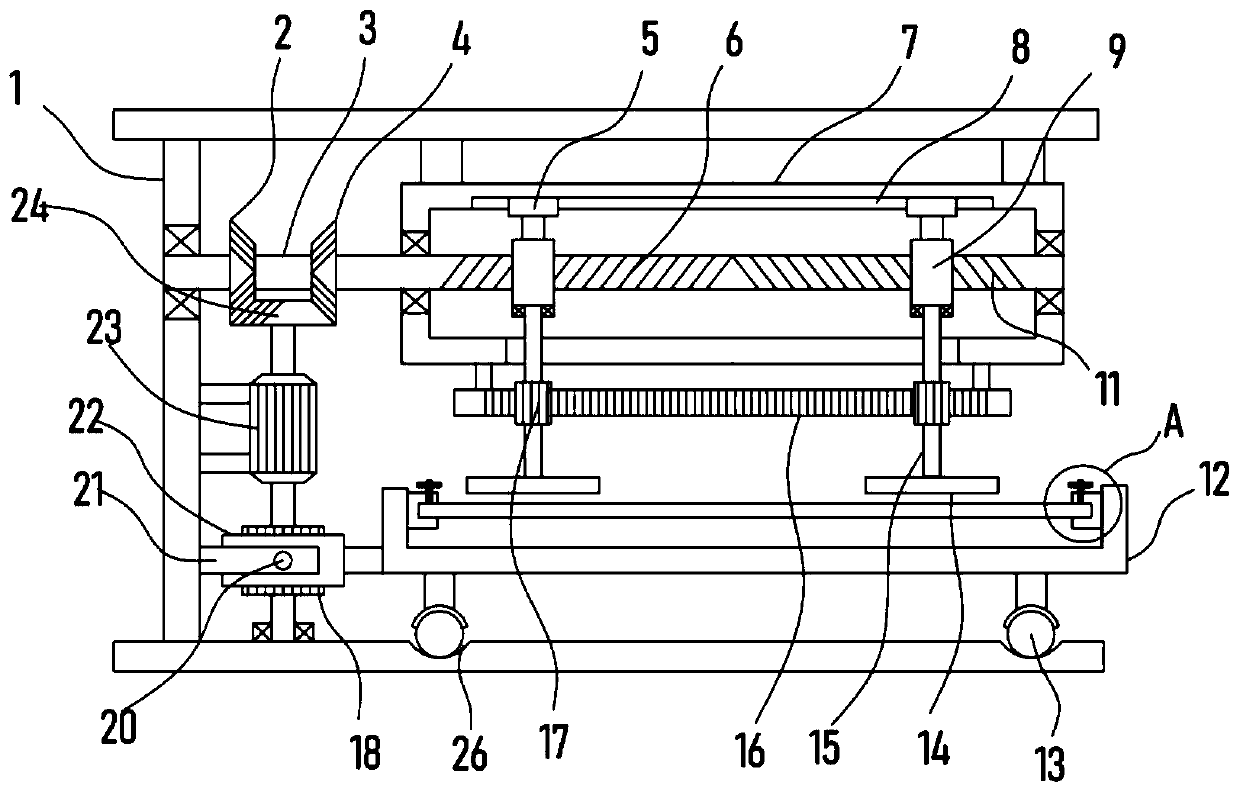

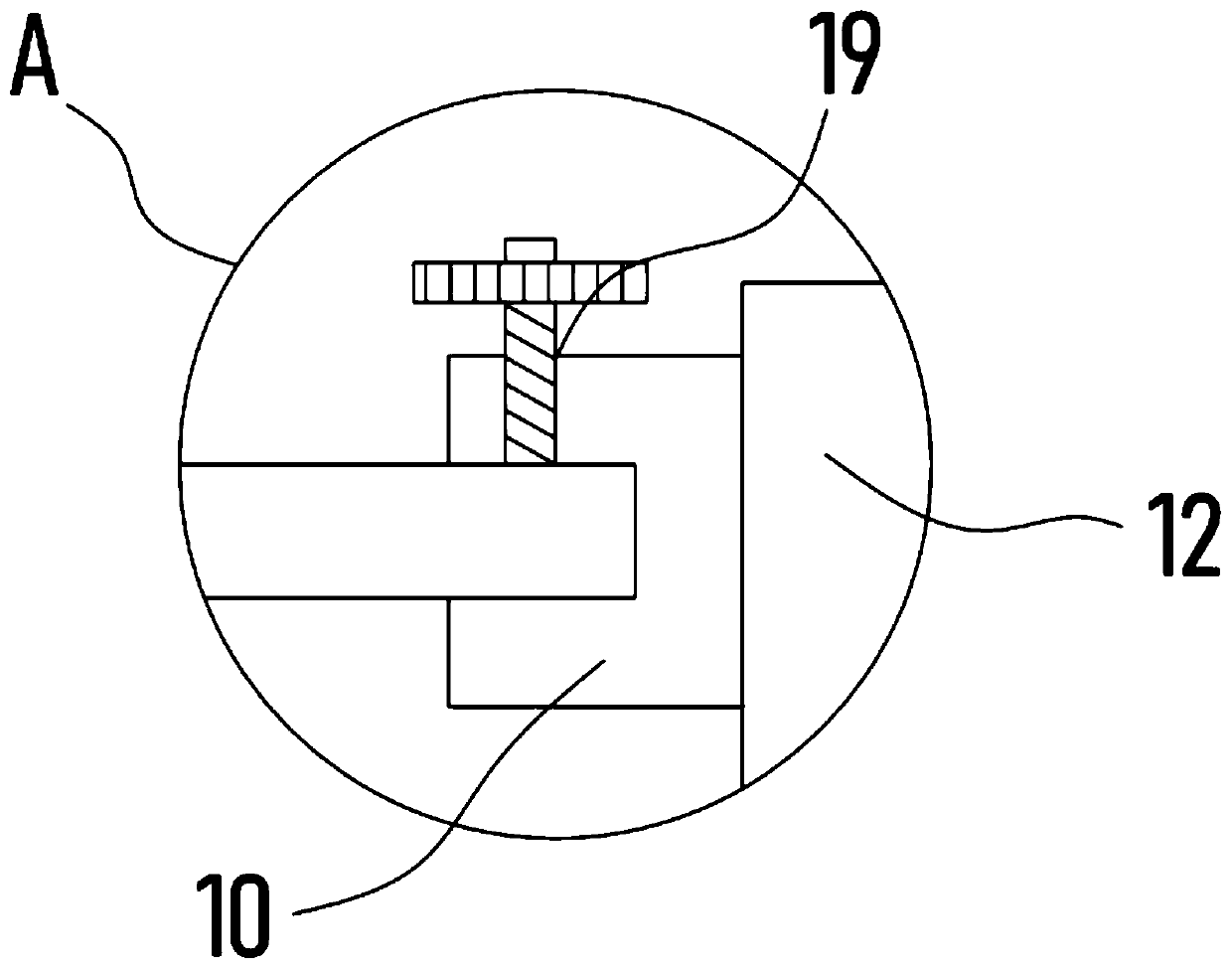

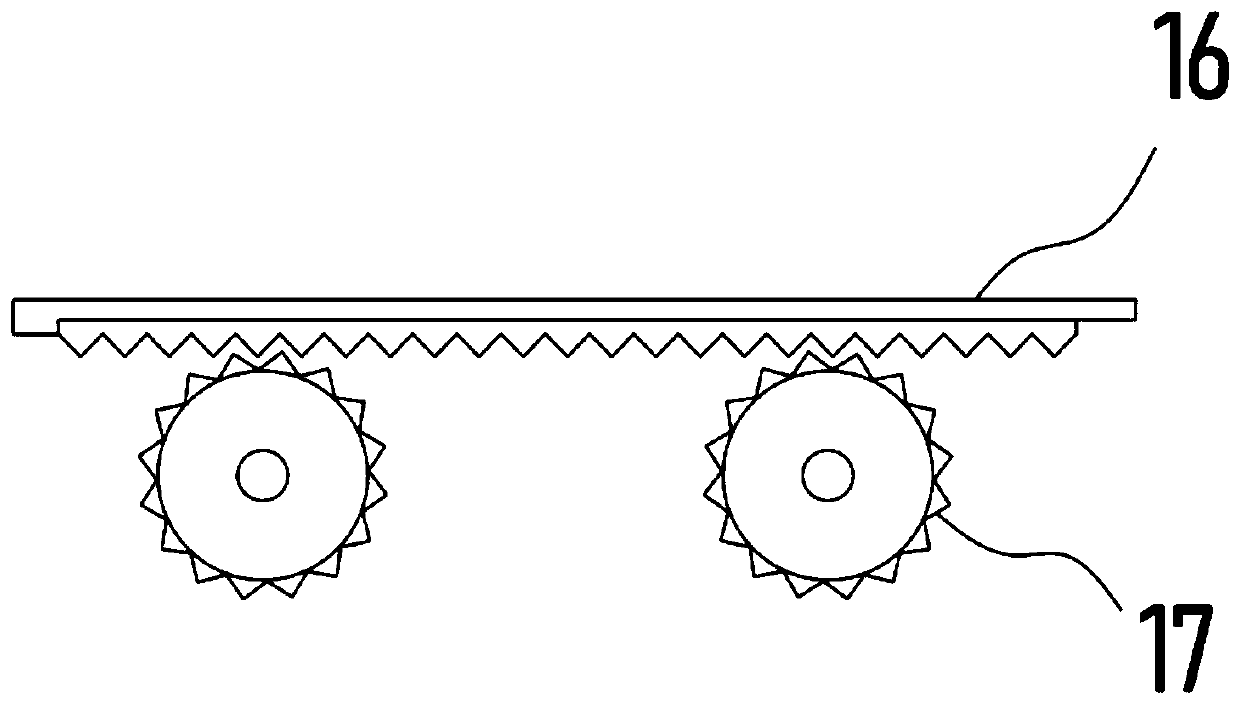

[0021] see Figure 1-3 , a basketball backboard surface polishing device, comprising a support frame 1, a mobile frame 12 is slidably installed on the support frame 1, and a clamping block 10 for clamping the backboard is symmetrically provided on the mobile frame 12, and the inner top of the support frame 1 is fixed An operation box 7 is installed, and the inside of the operation box 7 is rotated and horizontally provided with a rotating shaft 3. On the rotating shaft 3, external threads I6 and external threads II11 with opposite directions of rotation are symmetrically tapped, and both external threads I6 and external threads II11 are threaded. A threaded sleeve block 9 is sleeved. The rotation of the rotating shaft 3 can drive the threaded block 9 to move laterally through the external thread I6 and the external thread II11, and the rotating shaft 3 can carry out forward and reverse alternately so as to realize the movement of the two threaded blocks 9 towards or away from ...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, in the support frame 1, there is a circular frame 22 fixedly connected with the moving frame 12 that is vertical to the different planes of the length direction of the rotating shaft 3, and the inner wall of the circular frame 22 is symmetrically fixed with two Two internal racks 25, the rotary type in the back-shaped frame 22 is provided with an incomplete gear 18 that is intermittently meshed with two internal racks 25, and the incomplete gear 18 is fixedly connected with another output shaft of the biaxial motor 23.

[0029] The biaxial motor 23 can drive the incomplete gear 18 to rotate, and the incomplete gear 18 can be alternately meshed with two inner racks 25 to drive the circular frame 22. The circular frame 22 can perform reciprocating motion, and the circular frame 22 Drive the moving frame 12 fixedly connected with it to reciprocate, the moving direction of the moving frame 12 is perpendicular to the moving direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com