Sorting and storage method for nickel laminates

A storage method and lamination technology, applied in sorting and other directions, can solve the problems of long time-consuming manual sorting, prolonging the production cycle, and difficulties in collecting and sorting electroformed nickel laminations, so as to reduce the cost of manual sorting and improve demoulding The effect of success rate and shortening of manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The concrete implementation process of the present invention is described in detail below in conjunction with accompanying drawing and embodiment, specifically as follows:

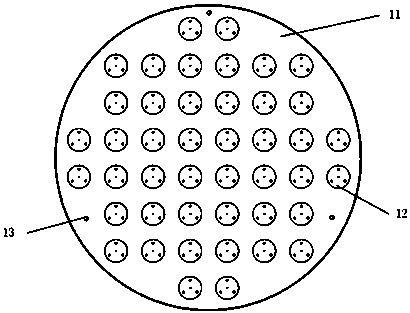

[0022] Step 1: If figure 1 Shown is a schematic of the substrate when electroforming is complete. There are three positioning holes on the base plate, on the corresponding first storage unit (such as figure 2 shown) has three positioning posts. Use a vacuum chuck to pick up the mask substrate, put the mask into a special solvent to remove the photoresist.

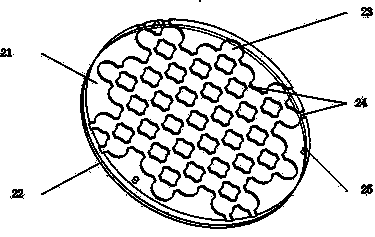

[0023] Step 2: If image 3 Shown is a schematic diagram of the assembly of the base plate and the first storage unit. The base plate and the first storage unit are assembled and compressed, and put into the ultrasonic device with the first storage unit below. Fill the space between the substrate and the first storage unit with deionized water.

[0024] Step 3: Turn on the ultrasonic device, and use ultrasonic to separate the nickel laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com