Circulation pulverizing device for device for promoting soil remediation through power ultrasounds

A soil remediation and cyclic pulverization technology, applied in the field of soil remediation, can solve the problems of low pulverization efficiency and inability to pulverize the soil to a clay-like shape, and achieve the effects of improving efficiency, uniform force and uniform pulverization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

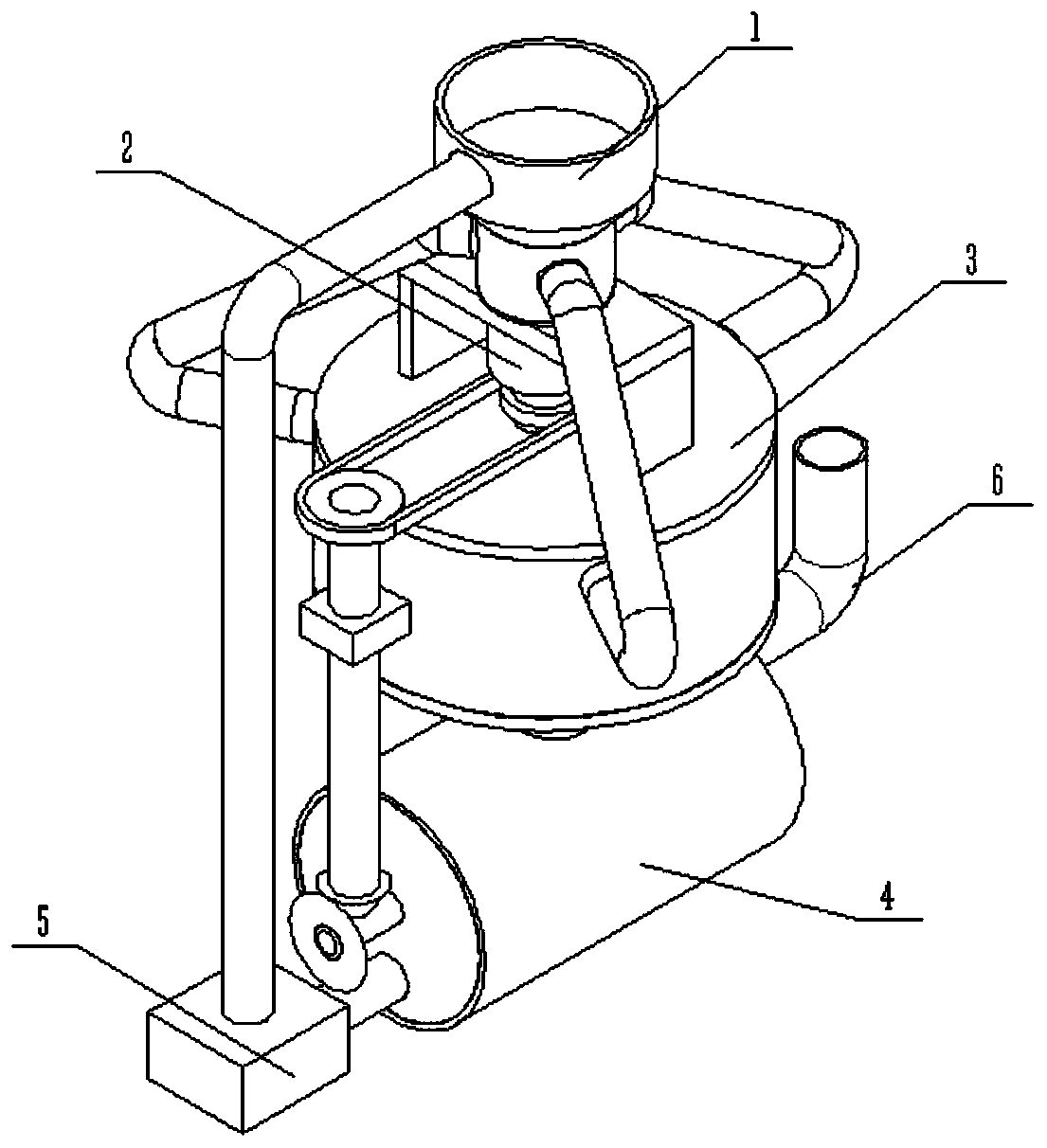

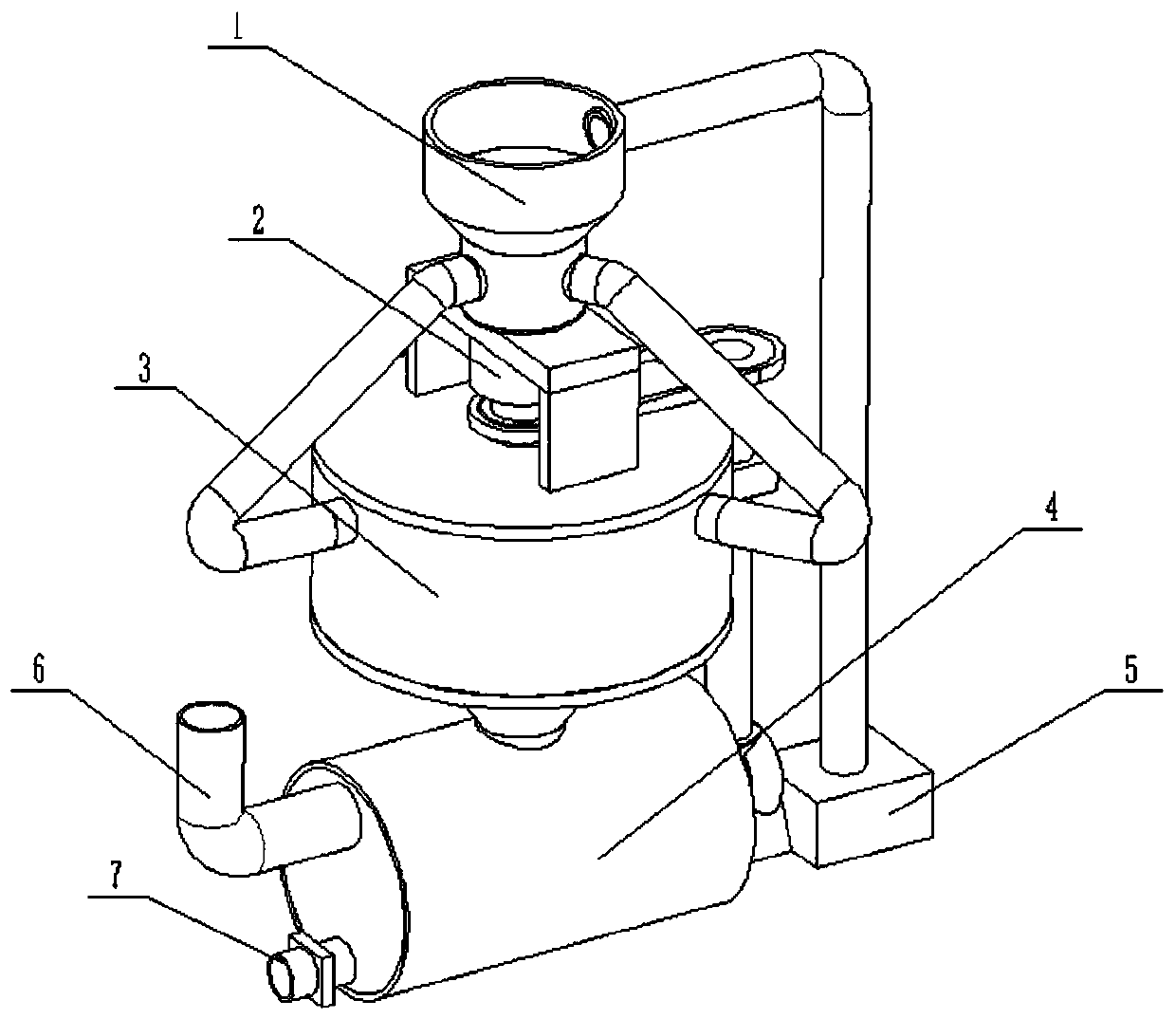

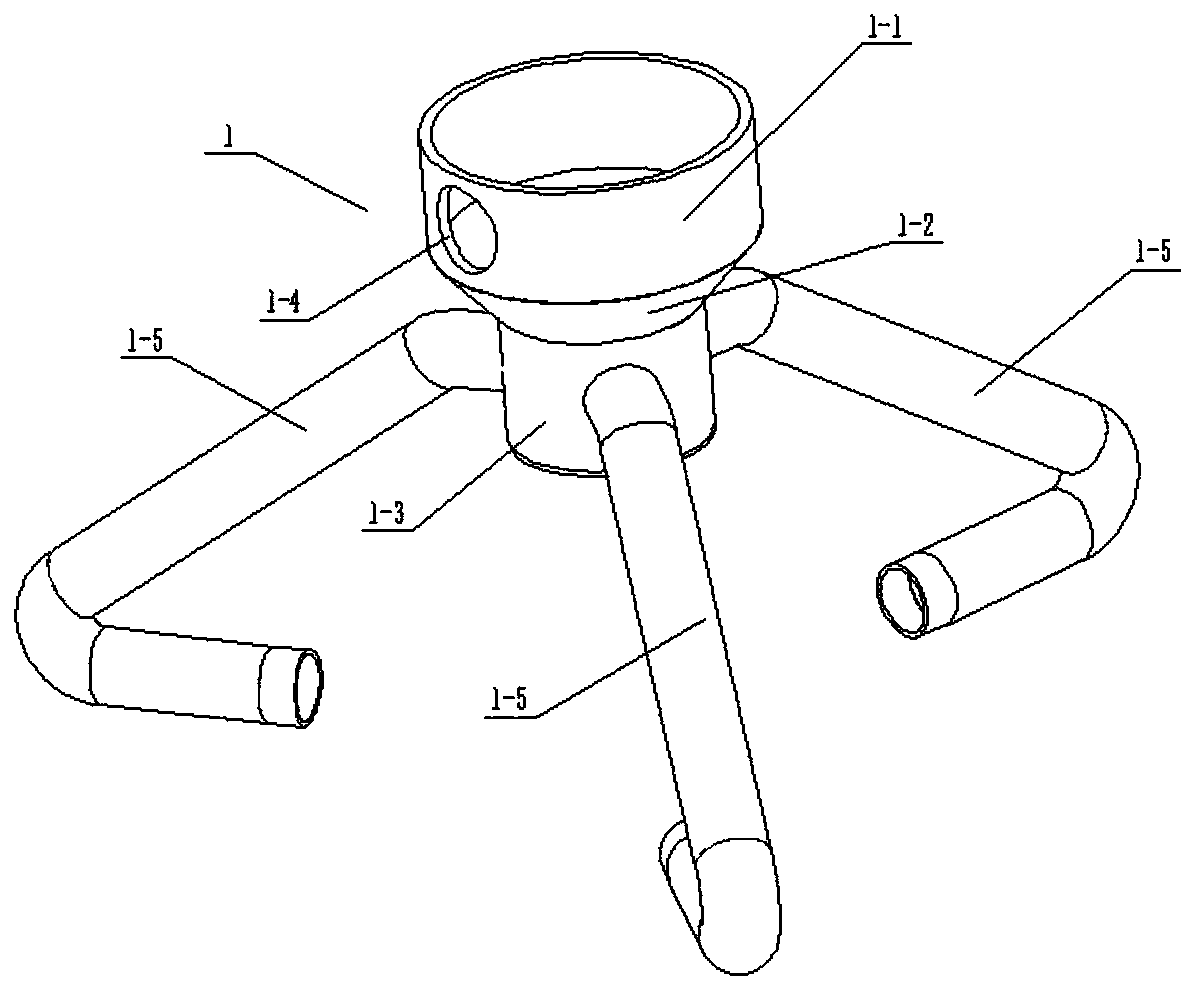

[0027] Such as Figure 1 to Figure 9 As shown, the circulating crushing device for the power ultrasonic promoting soil remediation device includes a circulating shunt pipe 1, a circulating pulverizer 2, a pulverizing tank 3, a stirring tank 4, a circulating pump 5, a water inlet pipe 6 and a recovery pipe 7 with a valve. The circulation distribution pipe 1 includes a circulation feed hopper 1-1, an upper cone bucket 1-2, a distribution hopper 1-3, a circulation feed hole 1-4 and three distribution pipes 1-5, and a circulation feed hopper 1-1 It is fixedly connected to the upper end of the upper cone bucket 1-2, and the lower end of the upper cone bucket 1-2 is fixedly connected to the splitter bucket 1-3, and the upper cone bucket 1-2 is connected to the circulating feed hopper 1-1 and the splitter bucket 1-3, and the circulation The feed hole 1-4 is set at the left end of the circulating feed hopper 1-1, and the upper ends of the three distribution pipes 1-5 are uniformly and...

specific Embodiment approach 2

[0034] Such as Figure 1 to Figure 9 As shown, this embodiment further describes the first embodiment, and the distances between the plurality of pulverizing cutting blades 2-13 and the plurality of fixed cutting blades 3-6 are all less than 1 mm. It is convenient to chop the soil larger than 1mm to within 1mm and make it into clay for use.

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 9 As shown, this embodiment further describes the second embodiment, and the diameters of the multiple stirring holes 2-10 are all 2 mm. It can be better and more effectively stirred during the stirring process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com