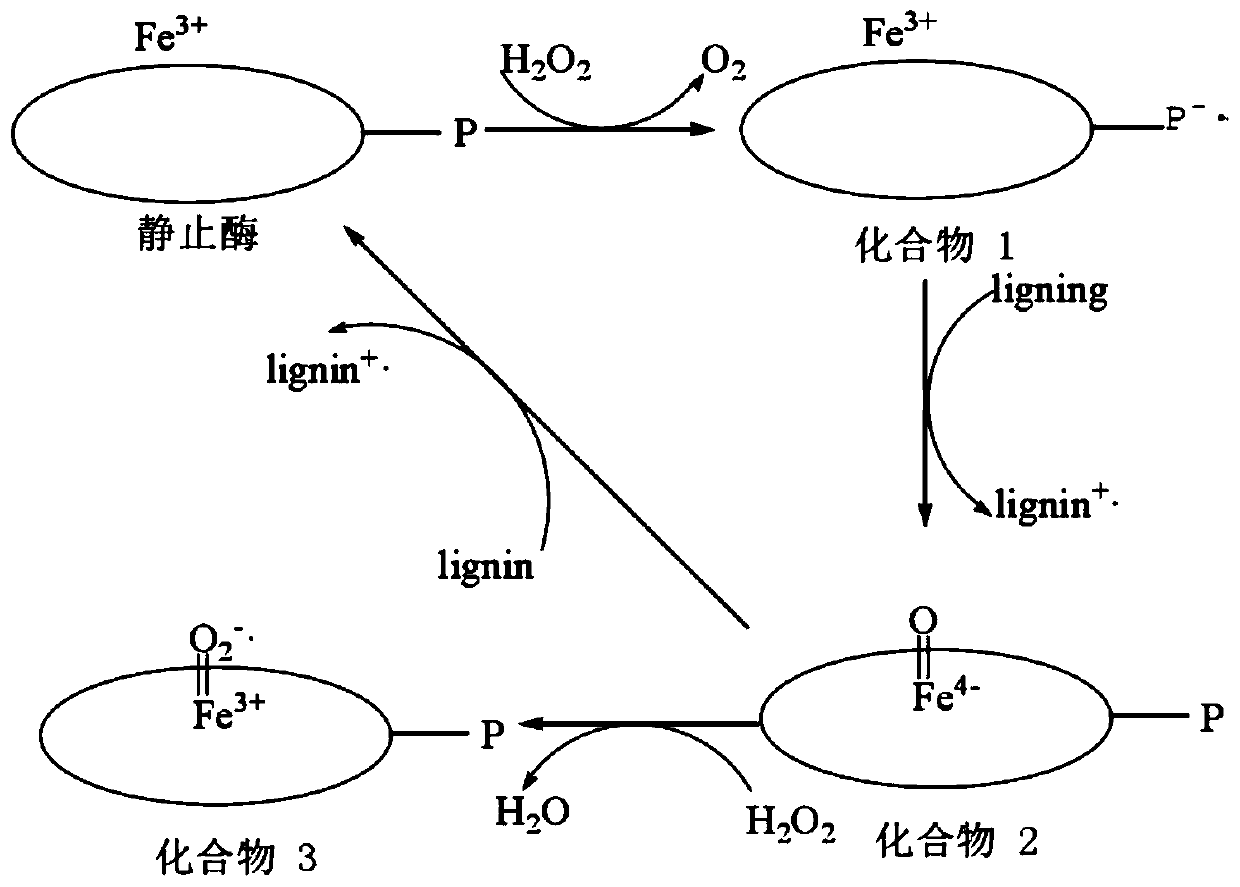

Method for improving quality of paper-making reconstituted tobacco by using Fe-CA/H2O2 biomimetic system

A technology of reconstituted tobacco leaf and papermaking method, which is applied in the fields of tobacco, application, and preparation of tobacco. It can solve the problems of product inherent quality and flavor adverse effects, poor coloring ability, poor selectivity, etc., and achieve good use conditions, not easy to turn yellow, fiber The effect of less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

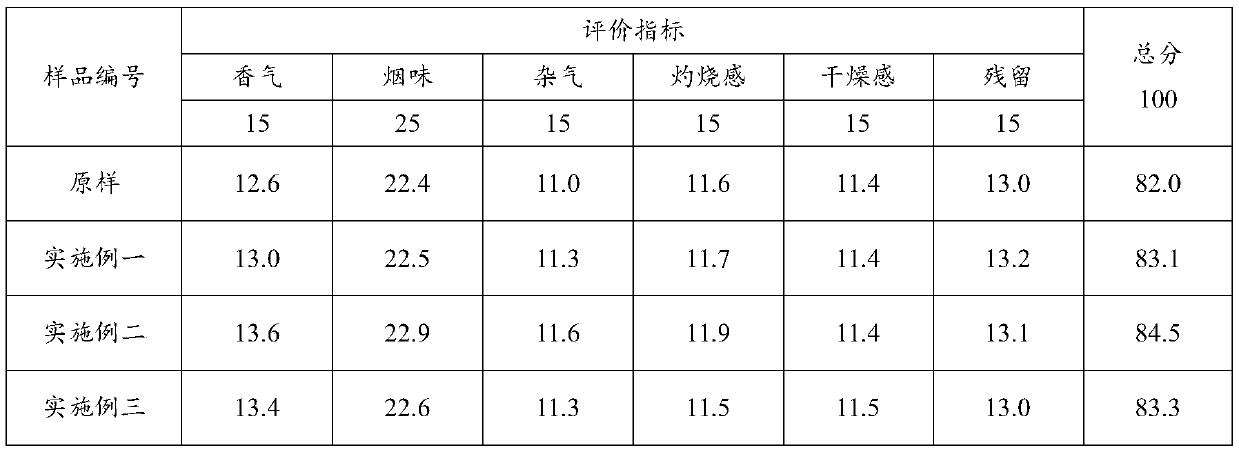

Examples

Embodiment 1

[0022] A method for improving the appearance color and quality of reconstituted tobacco leaves by papermaking method, comprising the following steps:

[0023] Step 1. The tobacco raw material is mixed with water, heated and extracted, and then filtered to obtain an extract solid and an extract, wherein the extraction temperature is 70° C., and the time is 40min, and the extract is refined and concentrated to obtain a coating. liquid;

[0024] In step 2, the solids of the extraction liquid are pulped according to the existing technology, and the pulp after beating is obtained by beating, and the beating degree is 30°SR. 2 O 2 Form Fe-CA / H 2 O 2 Imitation enzyme system, treatment temperature 50 ℃, time 20min, the iron-based imitation enzyme is 0.2mol / LFeSO 4 ·7H 2 O is mixed with 0.2mol / L polycarboxylic acid in a certain molar ratio, in which FeSO 4 : The molar ratio of Fe-EDTA (iron-based salt of EDTA) is 1:5, and the absolute dry mass ratio of the iron-based imitation en...

Embodiment 2

[0028] A method for improving the appearance color and quality of reconstituted tobacco leaves by papermaking method, comprising the following steps:

[0029] Step 1. The tobacco raw material is mixed with water, heated and extracted, and then filtered to obtain an extract solid and an extract, wherein the extraction temperature is 70° C., and the time is 40min, and the extract is refined and concentrated to obtain a coating. liquid;

[0030] In step 2, the solids of the extraction liquid are pulped according to the existing technology, and the pulp after beating is obtained by beating, and the beating degree is 30°SR. 2 O 2 Form Fe-CA / H 2 O 2 Imitation enzyme system, treatment temperature 65 ℃, time 40min, the iron-based imitation enzyme is 0.2mol / LFeSO 4 ·7H 2 O is mixed with 0.2mol / L polycarboxylic acid in a certain molar ratio, in which FeSO 4 : The molar ratio of Fe-EDTA (iron-based salt of EDTA) is 1:5, and the absolute dry mass ratio of iron-based imitation enzyme...

Embodiment 3

[0034] A method for improving the appearance color and quality of reconstituted tobacco leaves by papermaking method, comprising the following steps:

[0035] Step 1. The tobacco raw material is mixed with water, heated and extracted, and then filtered to obtain the solid matter of the extract and the extract, wherein the extraction temperature is 80 ° C, the time is 60min, the extract is fed and purified, and concentrated to obtain coating liquid;

[0036] In step 2, the solids of the extraction liquid are pulped according to the existing technology, and the pulp after beating is obtained by beating, and the beating degree is 30°SR. 2 O 2 Form Fe-CA / H 2 O 2 The imitation enzyme system, the treatment temperature is 80 ° C, the time is 60 minutes, and the iron-based imitation enzyme is 0.2mol / LFeSO 4 ·7H 2O is mixed with 0.2mol / L polycarboxylic acid in a certain molar ratio, in which FeSO 4 : The molar ratio of Fe-EDTA (iron-based salt of EDTA) is 1:5, and the absolute dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com