Water heater pipeline

A technology for water heaters and hot water pipes, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of wasting water resources, waiting for a long time, easy cooling of hot water, and cooling, so as to reduce waste and shorten waiting times. time, the effect of reducing the waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

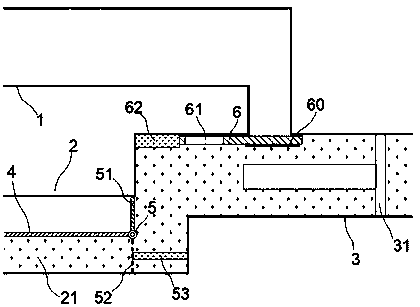

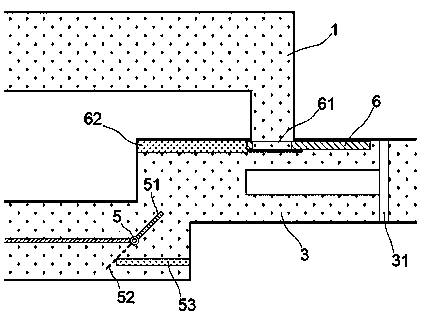

[0017] exist figure 1 , figure 2 In the embodiment shown, the water heater pipeline includes a cold water pipe 1 and a hot water pipe 2; the water inlet end of the hot water pipe 2 is communicated with the main body of the water heater, and the water outlet ends of the cold water pipe 1 and the hot water pipe 2 are connected to a mixing unit. The water pipe 3 is connected; a valve 31 is provided at the water outlet of the mixing pipe 3;

[0018] A separation film 4 extending along the axis of the hot water pipe 2 is arranged in the hot water pipe 2, and the separation film 4 is made of heat insulating material; the separation film 4 divides the hot water pipe 2 into two water channels 21, A control valve is installed at one end of the separation membrane 4 close to the water outlet end of the hot water pipe 2, the control valve includes a fixed rotating shaft arranged on the separation membrane 4, and a rotating drum 5 is sleeved on the fixed rotating shaft; 5 is fixedly pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com