High-power resilience dual drive resilience circulating water pump unit

A circulating water pump, dual-drive technology, applied in the direction of machine/engine, pump, pump device, etc., can solve the problems of limitation, slip, inability to automatically overrun the clutch or the direct-connected operation of the pneumatic tire clutch, etc., to reduce the conveying energy consumption, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with embodiment and accompanying drawing.

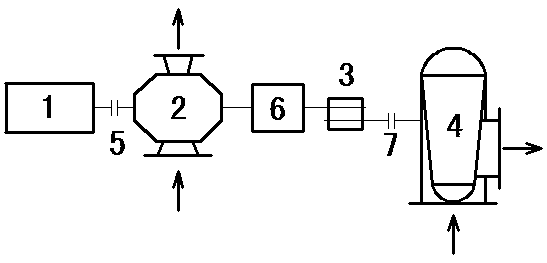

[0023] see figure 1 , a high-power energy-regenerating double-drive energy-regenerating circulating water pump unit, the circulating water pump 2 adopts a single-stage double-suction double-shaft extension mid-opening water pump, the motor 1 adopts a high-voltage rare earth permanent magnet synchronous motor, and the hydraulic turbine unit 4 is a mixed-flow type Water turbine unit; the motor 1 is connected to one end of the circulating water pump 2 through the first diaphragm coupling 5, the other end of the circulating water pump 2 is connected to the output shaft of the gearbox 3 through the pneumatic tire clutch 6, and the input shaft of the gearbox 3 passes through the first The two-diaphragm coupling 7 is connected with the output shaft of the hydraulic turbine unit 4 .

[0024] The gearbox 3 is a speed-up gearbox with the input shaft and the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com