Topological semi-metal material bismuth telluride and preparation method thereof

A semi-metal material, bismuth telluride technology, applied in chemical instruments and methods, polycrystalline material growth, self-solidification method, etc., to achieve the effect of improving the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of topological semimetal material bismuth telluride of the present invention comprises the following steps:

[0016] (1) Use Bi and Te of 5N purity as initial raw material, carry out weighing according to molar ratio Bi:Te=2:3, put into the quartz crucible that ultrapure water cleans, the crucible is evacuated to 10 -3 Pa level and sealed;

[0017] (2) Put the quartz crucible into a swing furnace at a temperature of 700°C to 1000°C, a swing speed of 10 turns / min to 20 turns / min, and a swing time of 15 to 30 minutes;

[0018] (3) The synthesized Bi 2 Te 3 The source material is placed in a crucible descending furnace for deposition and growth at a temperature of 750°C to 880°C. After 3 to 5 hours of holding time, the deposition and growth begin. The growth rate is 2 mm / day to 5 mm / day, and the growth days are 2 to 5 days .

[0019] The topological semimetal material bismuth telluride prepared by the above preparation method.

[0020] Bismuth t...

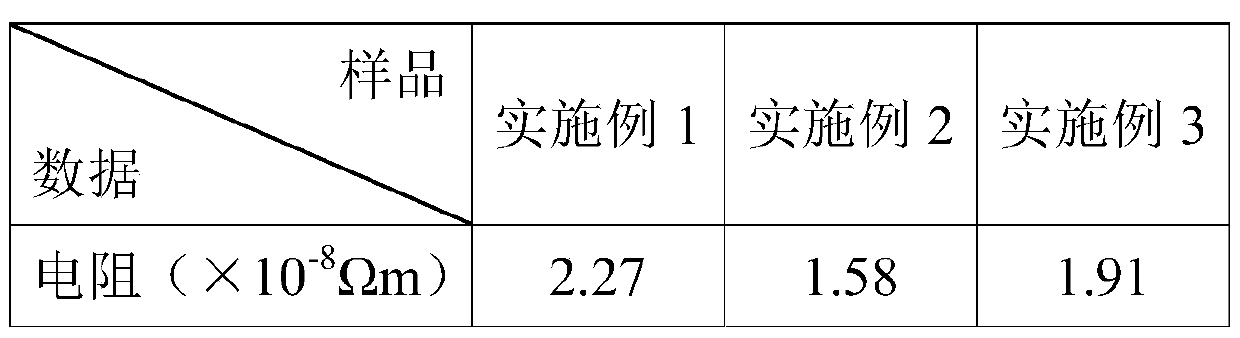

Embodiment 1

[0022] Select Bi and Te with 5N purity as initial raw materials, weigh 20 g according to the stoichiometric ratio of molar ratio Bi:Te=2:3, put into a quartz crucible cleaned with ultrapure water, and vacuumize the crucible to 10 -3 Pa level and sealed; put the quartz crucible into a swing furnace at a temperature of 700°C, a swing speed of 10 cycles / min, and a swing time of 15 minutes; the synthesized Bi 2 Te 3 The source material is placed in a crucible descending furnace for deposition and growth at a temperature of 750 ° C. After 3 hours of heat preservation, the deposition and growth begin. The growth rate is 2 mm / day, and the growth days are 2 days.

Embodiment 2

[0024] Select Bi and Te with 5N purity as initial raw materials, weigh 20 g according to the stoichiometric ratio of molar ratio Bi:Te=2:3, put into a quartz crucible cleaned with ultrapure water, and vacuumize the crucible to 10 -3 Pa level and sealed; put the quartz crucible into a swing furnace at a temperature of 850°C, a swing speed of 15 cycles / min, and a swing time of 23 minutes; the synthesized Bi 2 Te 3 The source material was placed in a crucible descending furnace for deposition and growth at a temperature of 815°C. After 4 hours of heat preservation, the deposition and growth began. The growth rate was 3.5 mm / day, and the growth days were 3.5 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com