A new type of alloy powder for rail repair and a method for repairing rail surface damage

A technology of alloy powder and surface damage, applied in the field of additive manufacturing, can solve the problems of insufficient impact toughness of welding repair layer, difficulty in guaranteeing repair quality, and large waste of resources, etc., to achieve high work efficiency, improve corrosion resistance, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

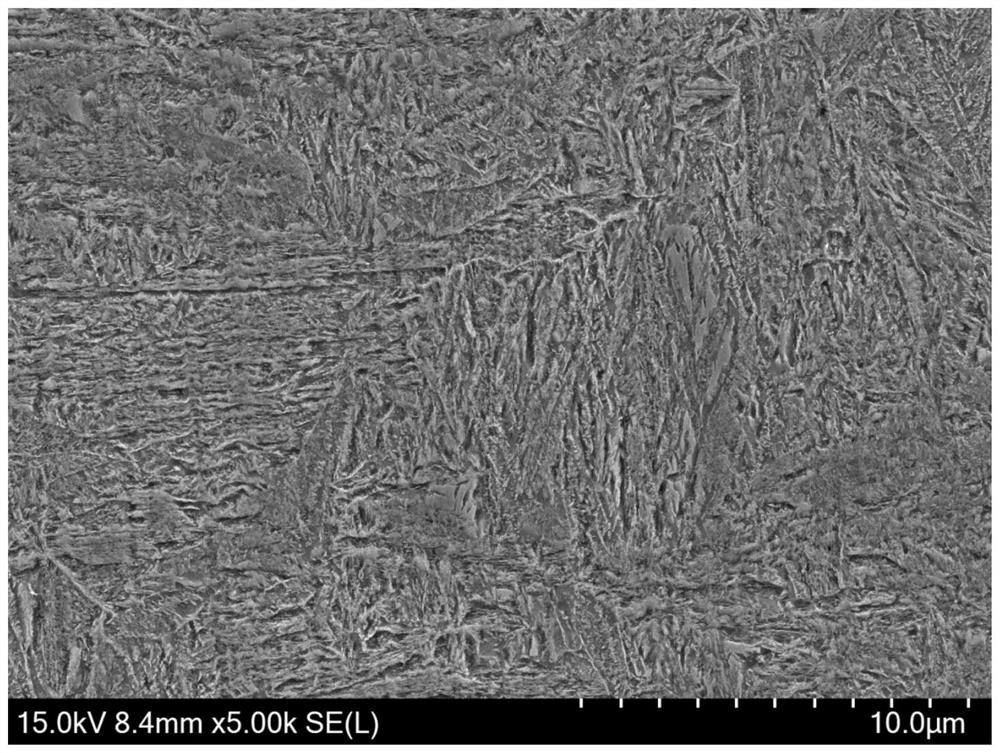

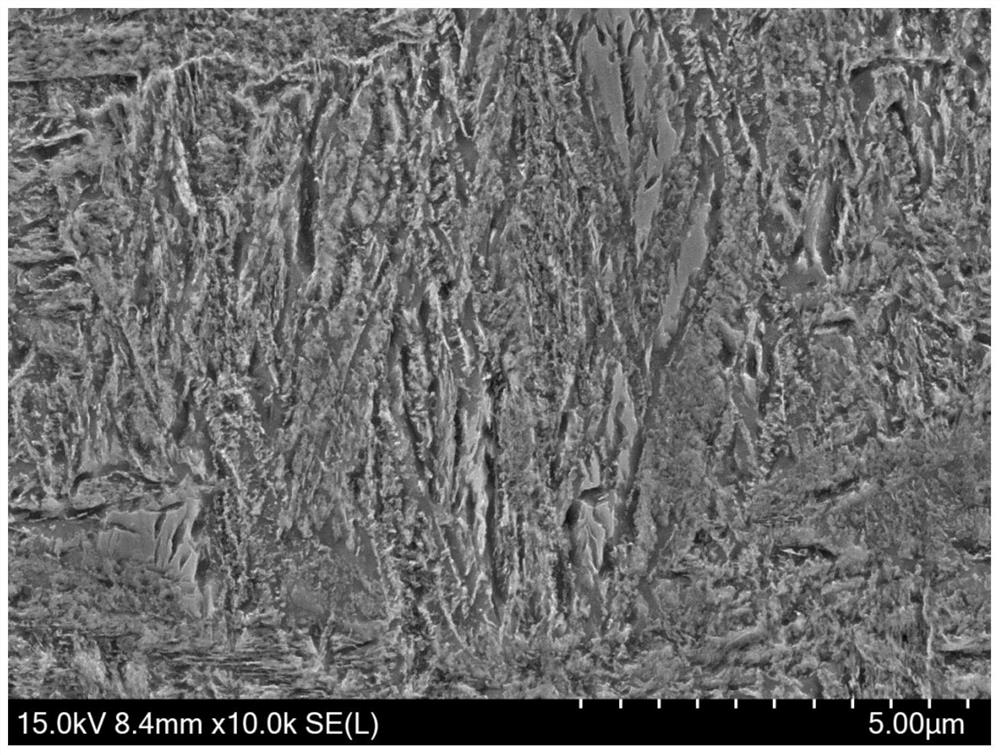

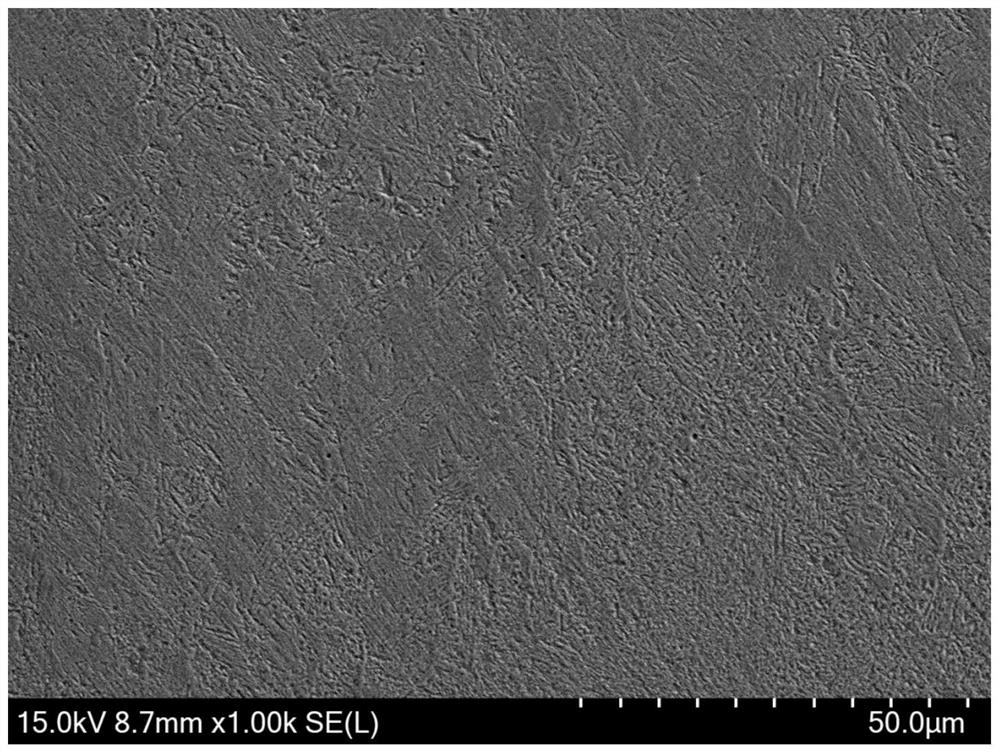

Image

Examples

Embodiment 1

[0028] The new alloy powder for rail repair includes the following components by weight percentage: 0.8% silicon, 0.61% manganese, 0.12% vanadium, 0.5% copper and 0.45% carbon, and the rest is iron.

[0029] The above-mentioned new type of alloy powder for rail repair is an alloy powder, which is obtained through a powder mixing process. The powder of metal manganese, metal copper, metal vanadium, metal iron, carbon block and raw silicon is used as raw materials for batching according to the target components. The purity of each component is greater than 99%, and the particle size of the obtained alloy powder is 250 mesh. In the powder mixing process of the alloy powder, the parameters of the powder mixing process are controlled so that the alloy powder does not produce segregation defects.

[0030] The method for repairing rail surface damage by using the above-mentioned new alloy powder for rail repair includes the following steps: (1) cleaning the damaged surface, removing i...

Embodiment 2

[0033] The new alloy powder for rail repair includes the following components by weight percentage: 1.5% silicon, 1.5% manganese, 0.15% vanadium, 0.8% copper and 0.7% carbon, and the rest is iron.

[0034] The above-mentioned new type of alloy powder for rail repair is alloy powder. The preparation method of alloy powder is according to the preparation method of alloy powder in Example 1. The particle size of the obtained alloy powder is 250 mesh. In the powder mixing process of alloy powder, control mixing The powder process parameters make the alloy powder not produce segregation defects.

[0035]The method for repairing rail surface damage by using the above-mentioned new alloy powder for rail repair includes the following steps: (1) cleaning the damaged surface, removing impurities such as floating rust, dust, oil stains, ensuring the cleanliness of the repaired surface, and preventing impurities from affecting the joint The composition of the ingredients reduces the compr...

Embodiment 3

[0038] The new alloy powder for rail repair includes the following components by weight percentage: 0.6% carbon, 1.2% silicon, 0.8% manganese, 0.15% vanadium and 0.6% copper, and the rest is iron.

[0039] The above-mentioned new type of alloy powder for rail repair is alloy powder. The preparation method of alloy powder is according to the preparation method of alloy powder in Example 1. The particle size of the obtained alloy powder is 250 mesh. In the powder mixing process of alloy powder, control mixing The powder process parameters make the alloy powder not produce segregation defects.

[0040] The method for repairing rail surface damage by using the above-mentioned new alloy powder for rail repair includes the following steps: (1) cleaning the damaged surface, removing impurities such as floating rust, dust, oil stains, ensuring the cleanliness of the repaired surface, and preventing impurities from affecting the joint The composition of the ingredients reduces the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com