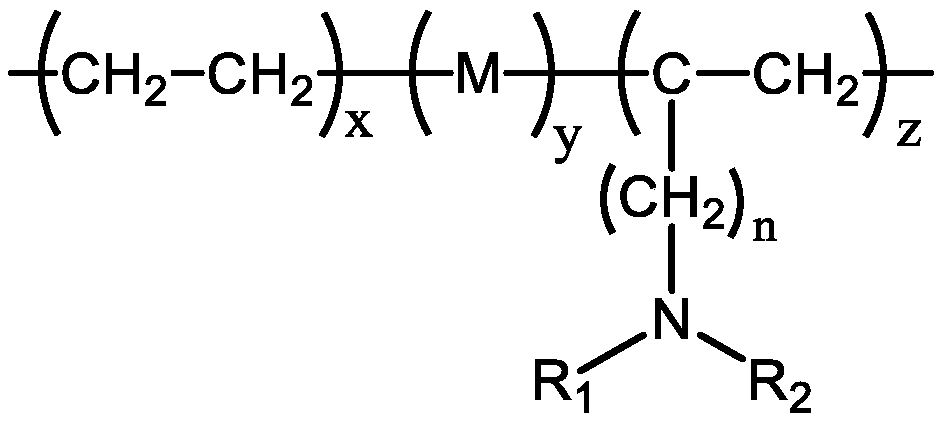

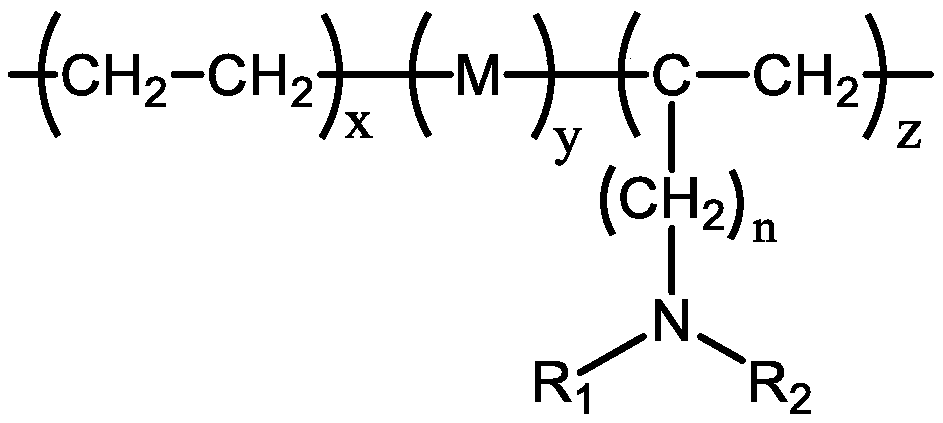

Amino-functionalized-polyolefin-elastomer-toughened nylon composite material and production method thereof

A technology of polyolefin elastomer and nylon composite materials, which is applied in the field of polymer composite materials to achieve good tensile strength, excellent mechanical properties, poor toughness, non-toxic and tasteless effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

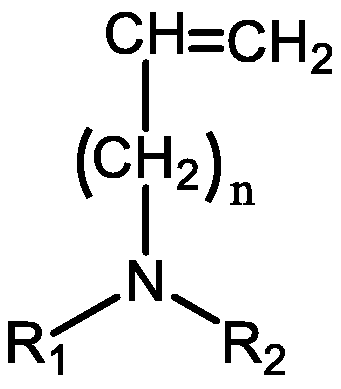

Method used

Image

Examples

preparation example 1

[0020] Synthesis steps of amino-functionalized polyolefin elastomer: adopt cationic metallocene coordination polymerization method, add 80g of octene and 30g of allylamine to 1L of alkane mixed solvent, make a solution with a concentration of 1g / 10ml, and then add it to the reaction In the kettle, after heating up to 120°C, ethylene gas was introduced to control the pressure inside the kettle to 2.5MPa. Add 1 mg of the main catalyst dimethylsilyl-tert-butylaminoindenyl titanium dichloride and 0.25 ml of the co-catalyst 10 wt % methylalumoxane toluene solution into the reactor, stir and react for 15 minutes to obtain a reactant solution, and transfer the reaction solution to The solid was precipitated in absolute ethanol, filtered and dried to obtain an amino-functionalized polyolefin elastomer with an insertion rate of the amino-functionalized monomer used in Examples 1-5 of 5 wt%.

preparation example 2

[0022] Synthesis steps of amino-functionalized polyolefin elastomer: adopt cationic metallocene coordination polymerization method, add 90g of octene and 10g of allylamine to 1L of alkane mixed solvent, make a solution with a concentration of 1g / 10ml, and then add it to the reaction In the kettle, after heating up to 120°C, ethylene gas was introduced to control the pressure inside the kettle to 2.5MPa. Add 1 mg of the main catalyst dimethylsilyl-tert-butylaminoindenyl titanium dichloride and 0.25 ml of the co-catalyst 10 wt % methylalumoxane toluene solution into the reactor, stir and react for 15 minutes to obtain the reactant solution, and transfer the reaction solution to The solid was precipitated into absolute ethanol, filtered and dried to obtain an amino-functionalized polyolefin elastomer with an insertion rate of the amino-functionalized monomer used in Example 6 of 2 wt%.

preparation example 3

[0024] Synthesis steps of amino-functionalized polyolefin elastomer: adopt cationic metallocene coordination polymerization method, add 75g of octene and 25g of allylamine to 1L of alkane mixed solvent, make a solution with a concentration of 1g / 10ml, and then add it to the reaction In the kettle, after heating up to 120°C, ethylene gas was introduced to control the pressure inside the kettle to 2.5MPa. Add 1 mg of the main catalyst dimethylsilyl-tert-butylaminoindenyl titanium dichloride and 0.25 ml of the co-catalyst 10 wt % methylalumoxane toluene solution into the reactor, stir and react for 15 minutes to obtain the reactant solution, and transfer the reaction solution to The solid was precipitated into absolute ethanol, filtered and dried to obtain an amino-functionalized polyolefin elastomer with an insertion rate of the amino-functionalized monomer used in Example 7 of 4 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com