PET film with good oxygen barrier performance

A technology of oxygen barrier and performance, applied in the field of new materials, it can solve the problems of poor oxygen barrier property and can not meet the barrier packaging, etc., and achieve the effect of improving tensile strength, reducing the gap between molecules, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

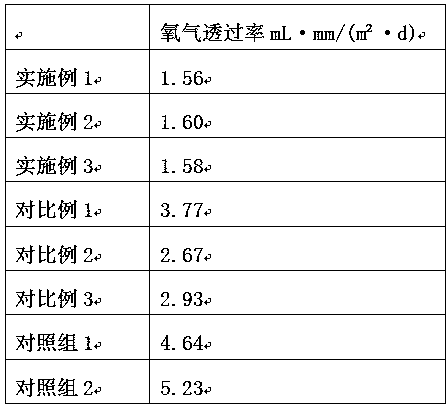

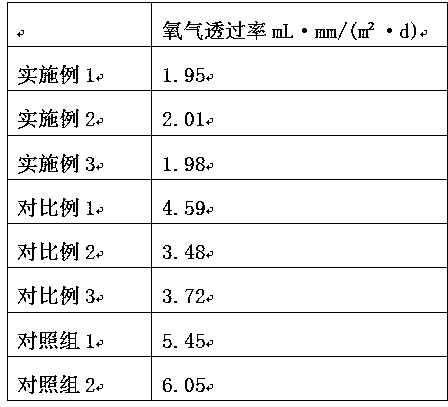

Examples

Embodiment 1

[0020] A PET film with good oxygen barrier performance, made of the following components in parts by weight: 4-chloro-2-nitroaniline modified PET polyester chip 90, dopamine modified rosin resin 31, nanometer zinc dioxide 8 , trioctyl phosphate 1.2, glyceryl stearate 2, hydroxypropyl acrylate 1.8, sodium sulfosuccinate 0.5; the dopamine-modified rosin resin contains 20% of its quality nano-sericite.

[0021] Further, the preparation method of the 4-chloro-2-nitroaniline modified PET polyester chip comprises the following steps:

[0022] (1) Dissolving 4-chloro-2-nitroaniline in a hydrochloric acid solution with a concentration of 2.3mol / L to obtain a modified solution;

[0023] (2) Add PET polyester chips to the modified solution prepared above, under the protection of inert gas, heat to 90°C, stir at 200r / min for 2 hours, then filter, vacuum dry to constant weight, and get Pre-modified PET polyester chips;

[0024] (3) Add the PET polyester chips obtained above into the rea...

Embodiment 2

[0034] A PET film with good oxygen barrier performance, made of the following components in parts by weight: 4-chloro-2-nitroaniline modified PET polyester chip 93, dopamine modified rosin resin 35, nanometer zinc dioxide 12 , trioctyl phosphate 1.5, glyceryl stearate 5, hydroxypropyl acrylate 2.2, sodium sulfosuccinate 0.8; the dopamine-modified rosin resin contains 25% of its quality nano-sericite.

[0035] Further, the preparation method of the 4-chloro-2-nitroaniline modified PET polyester chip comprises the following steps:

[0036] (1) Dissolving 4-chloro-2-nitroaniline in a hydrochloric acid solution with a concentration of 2.3mol / L to obtain a modified solution;

[0037] (2) Add PET polyester chips to the modified solution prepared above, under the protection of inert gas, heat to 92°C, stir at 200r / min for 2 hours, then filter, vacuum dry to constant weight, and get Pre-modified PET polyester chips;

[0038] (3) Add the PET polyester chips obtained above into the re...

Embodiment 3

[0048] A PET film with good oxygen barrier performance, made of the following components in parts by weight: 4-chloro-2-nitroaniline modified PET polyester chip 91, dopamine modified rosin resin 32, nano zinc dioxide 10 , trioctyl phosphate 1.3, glyceryl stearate 4, hydroxypropyl acrylate 1.9, sodium sulfosuccinate 0.6; the dopamine-modified rosin resin contains 22% of its quality nano-sericite.

[0049] Further, the preparation method of the 4-chloro-2-nitroaniline modified PET polyester chip comprises the following steps:

[0050] (1) Dissolving 4-chloro-2-nitroaniline in a hydrochloric acid solution with a concentration of 2.3mol / L to obtain a modified solution;

[0051] (2) Add PET polyester chips to the modified solution prepared above, under the protection of inert gas, heat to 91°C, stir at 200r / min for 2 hours, then filter, vacuum dry to constant weight, and get Pre-modified PET polyester chips;

[0052] (3) Add the PET polyester chips obtained above into the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com