Wood powder modified renewable polyvinyl chloride composition and preparation method thereof

The technology of polyvinyl chloride and the composition is applied in the field of wood powder modified regenerated polyvinyl chloride composition and its preparation field, which can solve the problems of poor product mechanical properties, large difference in bulk density, easy scorching of wood powder, and the like, To achieve the effect of improving adhesion of wood powder and improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take by weighing 100 parts by weight of regenerated polyvinyl chloride and 1 part by weight of ethylene bis-stearamide, add in the mixer, and mix for 2 minutes at 600 rpm;

[0035] (2) Add 25 parts by weight of 150 mesh wood powder, and mix for another 2 minutes at 300 rpm;

[0036] (3) Continue to add 2 parts by weight of polymethylene polyphenylisocyanate, 0.1 parts by weight of antioxidant 1010, and 0.2 parts by weight of antioxidant 168, mix at high speed for 2 minutes, and take it out for later use;

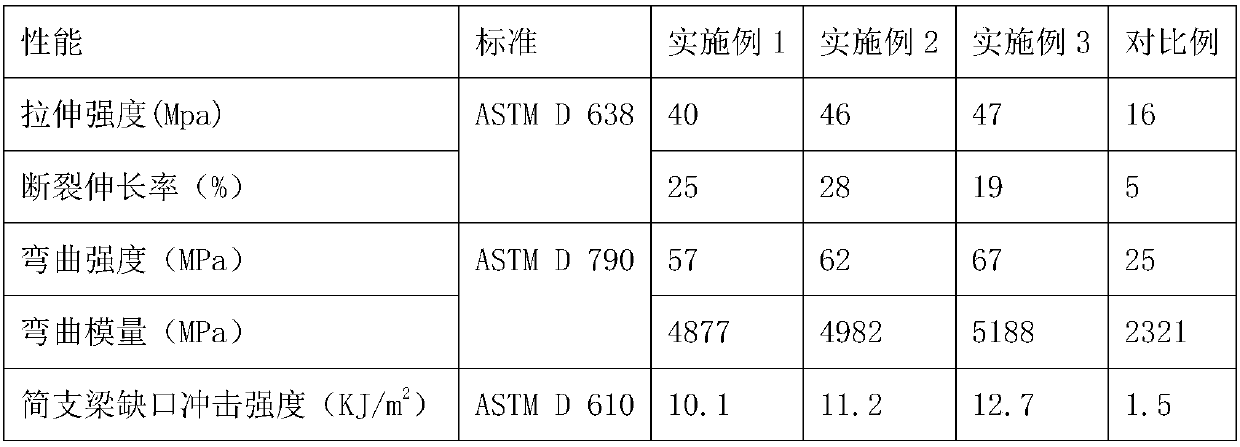

[0037] (4) Pre-compressing in a hot pressing mold, pressure 2MPa, time 10s; hot pressing molding, temperature 160°C, pressure 20MPa, time 5 minutes, to obtain the wood powder modified recycled polyvinyl chloride combination of the present invention The material was injection molded and tested for mechanical properties. The results are shown in Table 1.

Embodiment 2

[0039] (1) Take by weighing 100 parts by weight of regenerated polyvinyl chloride, 2 parts by weight of ethylene bis stearamide, add in the mixer, 800 rpm, mix for 5 minutes;

[0040] (2) Take 40 parts by weight of 120 mesh wood flour, add it to the mixer described in step (1), mix it for 5 minutes at 400 rpm;

[0041] (3) Continue to add 2.5 parts by weight of polymethylene polyphenylisocyanate, 0.1 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168, and 0.3 parts by weight of antioxidant DSTDP for high mixing for 1 min, and take it out for later use.

[0042] (4) Pre-compressing in a hot-pressing mould, pressure 3MPa, time 30s; hot-pressing, temperature 200°C, pressure 100MPa, time 30 minutes, to obtain the wood powder modified recycled polyvinyl chloride combination of the present invention The material was injection molded and tested for mechanical properties. The results are shown in Table 1.

Embodiment 3

[0044] (1) Take by weighing 100 parts by weight of regenerated polyvinyl chloride and 1 part by weight of ethylene bisstearamide and add it to the mixer, and mix for 5 minutes at 700 rpm;

[0045] (2) Take 55 parts by weight of 130 mesh wood flour, add it to the mixer described in step (1), and continue mixing for 5 minutes at 400 rpm;

[0046] (3) Continue to add 3 wt. parts of polymethylene polyphenylisocyanate, 0.2 wt. parts of antioxidant 1010, 0.3 wt.

[0047] (4) Pre-compressing in a hot-pressing mould, pressure 2.5MPa, time 25s; hot-pressing molding, temperature 180°C, pressure 50MPa, time 10 minutes, the wood flour modified recycled polyvinyl chloride of the present invention is obtained The composition was injection molded and tested for mechanical properties. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com