Aging-resistant rubber belt track

A rubber crawler and anti-aging technology, which is applied in the field of rubber materials and its preparation, can solve the problems of insufficient strength, aging and aging performance of the rubber crawler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

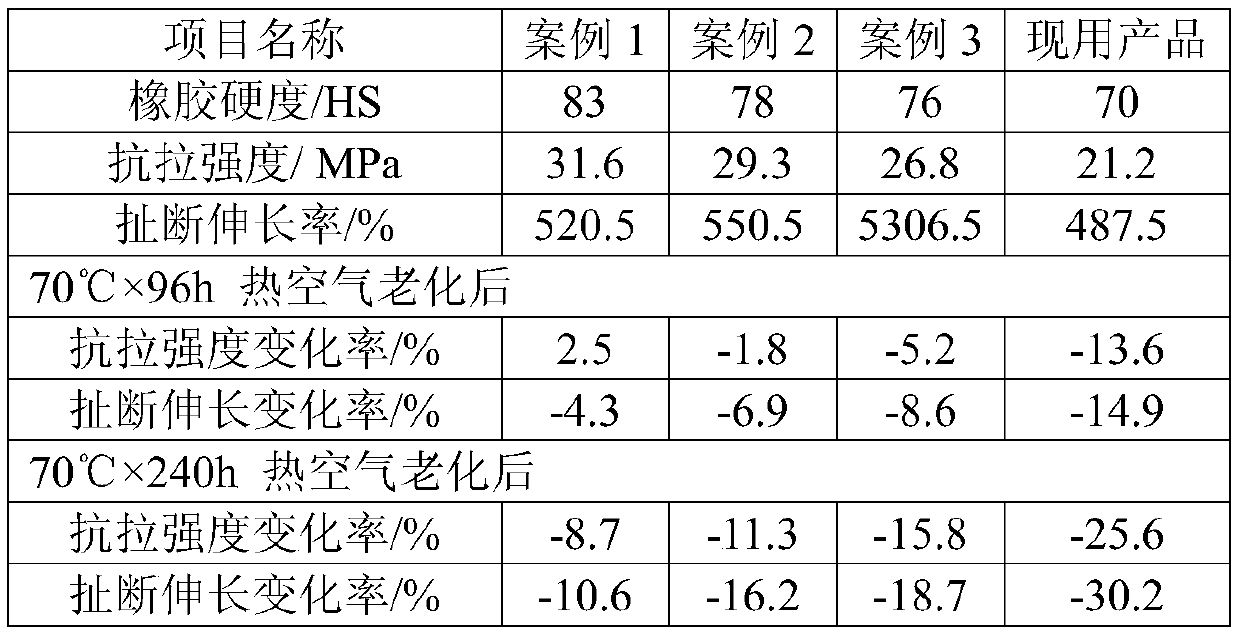

Examples

preparation example Construction

[0034] The preparation method of described aging-resistant rubber track is as follows:

[0035] step one:

[0036] Preparation of ingredients: Prepare accelerators AZ and / or BZ, magnesium oxide, anti-scorch agent, silane coupling agent, stearic acid, low-density naphthenic oil and other compounding ingredients, crush and dry, sieve, weigh and put in according to the proportion Stir well in the container.

[0037] Step two:

[0038] Initial mixing: Set the speed ratio of the front and rear rollers of the open mill to 1:1.3, adjust the roll distance of the open mill to 1mm, add raw rubber for mastication, and add the ingredients in step 1 to continue mixing after the plasticization is completed.

[0039] Step three:

[0040] Mixing: Adjust the roller distance of the open mill to 0.8mm, and then mix the rubber after the initial mixing with calcium carbonate, flame retardant, and light stabilizer; after the mixing is completed, add carbon black, The ultra-fine activated clay i...

Embodiment 1

[0044] A kind of aging-resistant rubber track provided by the present embodiment, described aging-resistant rubber track comprises the following raw materials in parts by weight: 60 parts of EPDM rubber, 40 parts of neoprene rubber, 1 part each of accelerator BZ and TMTD, 3.5 parts of magnesium oxide, 4 parts of zinc oxide, 2 parts of antioxidant NBC, NMB, DFC-34, 40 parts of carbon black N550, 1 part of anti-scorch agent PVI, 1 part of silane coupling agent kh550, 1 part of stearic acid, 3 parts of low-density naphthenic oil, 15 parts of superfine activated clay, 4 parts of calcium carbonate, 1 part of light stabilizer PDS, 1 part of antimony trioxide, and 1 part of chlorinated paraffin.

[0045] step one:

[0046] Preparation of ingredients: Prepare accelerator BZ, magnesium oxide, anti-aging agent NBC, NMB, DFC-34, anti-scorch agent PVI, silane coupling agent kh550, stearic acid, low-density naphthenic oil and other compounding ingredients, crush and dry Sieve, weigh in pr...

Embodiment 2

[0054] A kind of aging-resistant rubber crawler provided by the present embodiment, described aging-resistant rubber crawler comprises the raw material of following parts by weight: EPDM rubber 60 parts, butadiene rubber 40 parts, accelerator AZ and TMTD each 1.5 parts, 4 parts of magnesium oxide, 4 parts of zinc oxide, 2.5 parts of antioxidant NMB, DFC-34, and CMA each, 50 parts of carbon black N770, 1.5 parts of anti-scorch agent PVI, 2 parts of silane coupling agent kh5502, 1.5 parts of stearic acid, low 3.5 parts of density naphthenic oil, 16 parts of superfine activated clay, 3.5 parts of calcium carbonate, 1.5 parts of light stabilizer PDS, 1.5 parts of antimony trioxide and 1.5 parts of decabromodiphenyl ether.

[0055] step one:

[0056] Preparation of ingredients: prepare accelerator AZ, magnesium oxide, anti-aging agent NMB, DFC-34, CMA, anti-scorch agent PVI, silane coupling agent kh550, stearic acid, low-density naphthenic oil and other compounding ingredients, cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com