Rotomolding-grade polyethylene filled modified composite material and preparation method thereof

A composite material and polyethylene technology, applied in the field of rotomolding grade materials, can solve the problems of poor antibacterial properties, poor mechanical properties, weak strength, etc., and achieve the effects of enhancing acid and alkali resistance, improving strength, and good bacteriostatic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

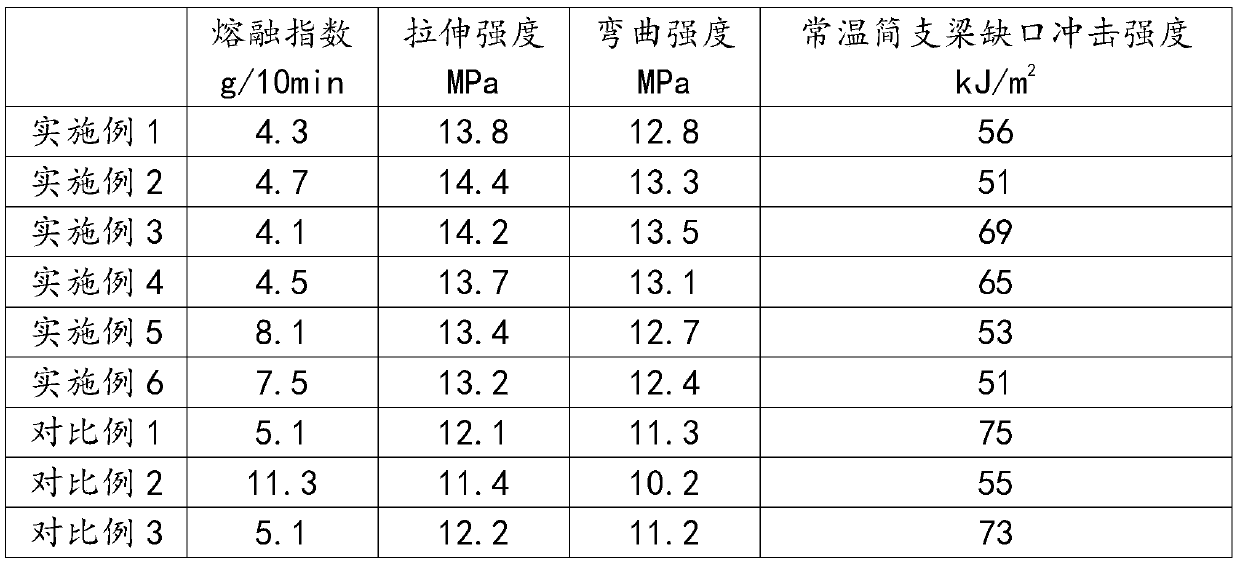

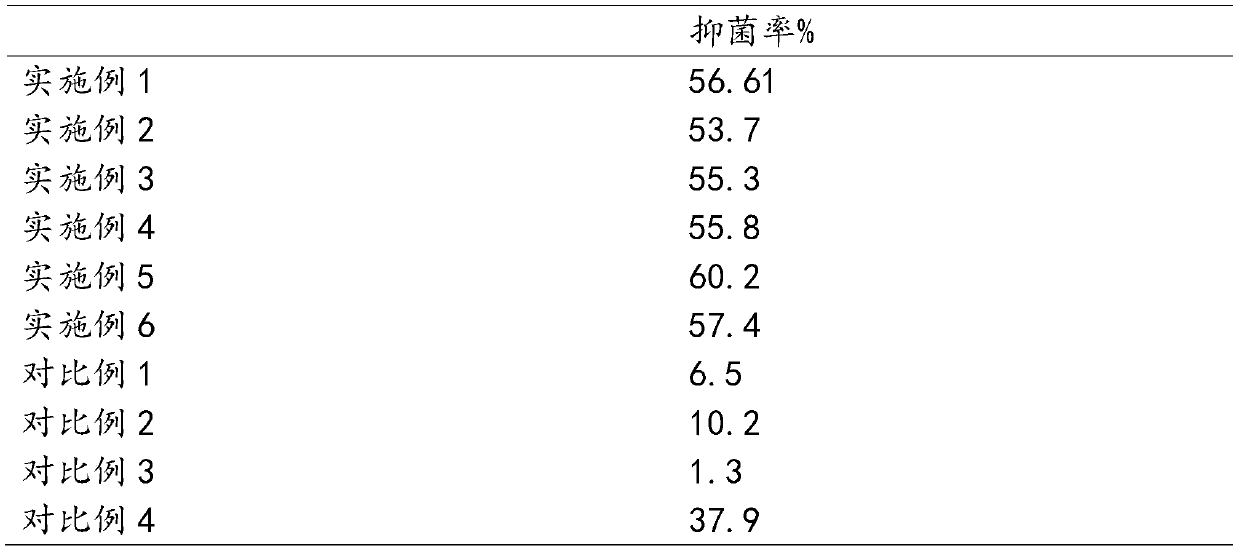

Examples

Embodiment 1

[0033] Preparation of a rotomoulding grade polyethylene filled modified composite material: 72 parts of linear low density polyethylene LLDPE1, 20 parts of glass beads, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of lubricant EBS -SF, 5 parts of POE-g-MAH, and 3 parts of PE grafted maleic anhydride were put into the low-speed mixer, mixed for 5 minutes, and the speed of the mixer was 20rpm; then the mixed materials were put into the co-rotating twin-screw extruder Extrusion and granulation in the extruder, the parameters of the extruder are: main engine speed 400rpm, main feeding frequency 10Hz, temperature 180-200°C, melt pressure ≤ 10MPa; put the granulated plastic particles into an oven for drying at a temperature of 90 ℃, dry for 2 hours; grind the dried plastic particles in a mill with a 40-mesh sieve, a grinding disc rotation speed of 4000rpm, a milling current of 60A, and a powder outlet temperature of ≤70°C.

Embodiment 2

[0035] Preparation of a modified composite material filled with rotomoulding grade polyethylene: add 66 parts of linear low density polyethylene LLDPE1, 25 parts of glass beads, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.3 part of lubricant EBS -SF, 6 parts of POE-g-MAH, and 3 parts of PE grafted maleic anhydride were put into the low-speed mixer and mixed for 8 minutes, and the speed of the mixer was 10rpm; then the mixed materials were put into the twin-screw extruder Extrusion granulation, extruder parameters are: host speed 350rpm, main feeding frequency 8Hz, temperature 180-200°C, melt pressure ≤ 10MPa; put the granulated plastic particles into an oven for drying, temperature 90°C, dry 2h; then grind the dried plastic particles in a mill with a 40-mesh sieve, a milling disc rotation speed of 4000rpm, a milling current of 55A, and a powder outlet temperature of ≤70°C.

Embodiment 3

[0037] Preparation of a modified composite material filled with rotomolding grade polyethylene: add 61 parts of linear low density polyethylene LLDPE1, 30 parts of glass beads, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of lubricant EBS -SF, 5 parts of POE-g-MAH, 4 parts of PE grafted maleic anhydride were put into the low-speed mixer and mixed for 10 minutes, and the speed of the mixer was 20rpm; then the mixed materials were put into the twin-screw extruder Extrusion granulation, extruder parameters: main engine speed 400rpm, main feeding frequency 12Hz, temperature 180-200°C, melt pressure ≤ 10MPa; put the granulated plastic particles into an oven for drying, temperature 90°C, dry 2h; then grind the dried plastic particles in a mill with a 40-mesh sieve, a milling disc rotation speed of 5000rpm, a milling current of 60A, and a powder outlet temperature of ≤70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com