A kind of method for continuously preparing isopentenol

A technology of prenol and butene, applied in the field of continuous preparation of prenol, can solve the problems of difficult separation, high production cost, long reaction time, etc., and achieve the reduction of regeneration links, short reaction cycle and safe reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

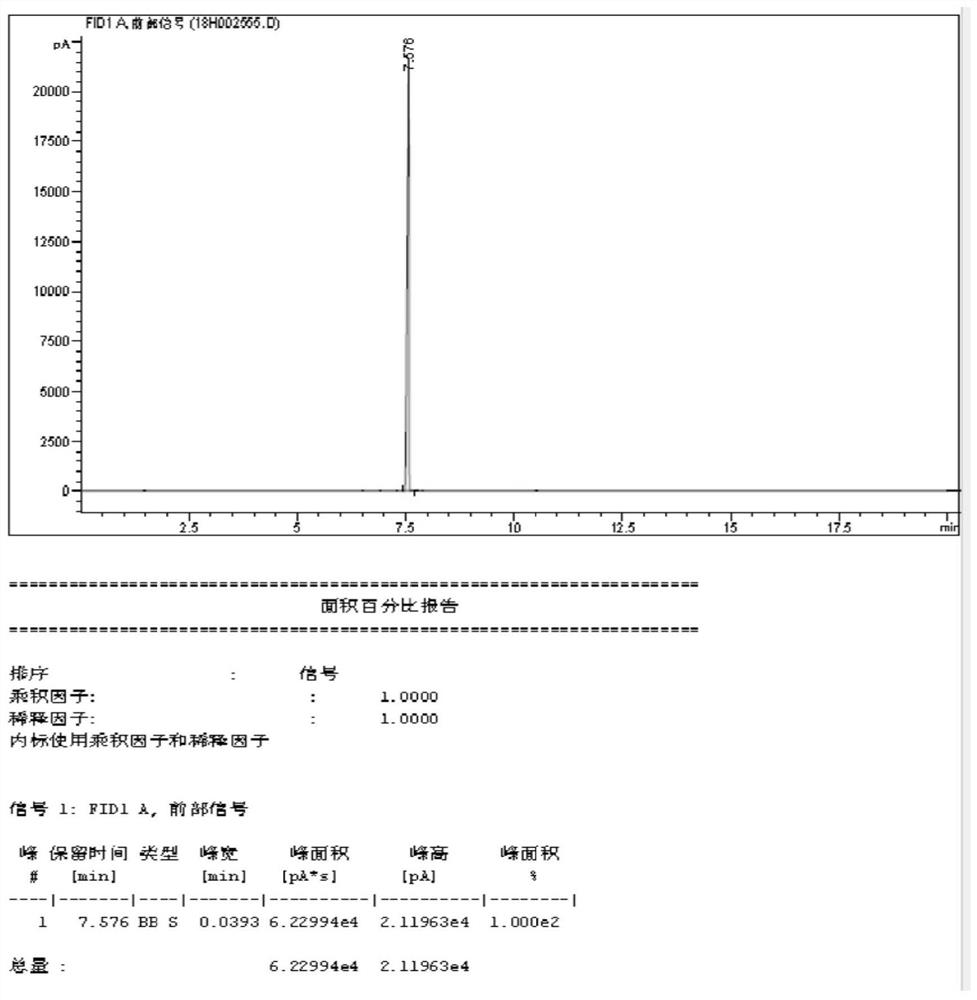

Embodiment 1

[0022] Weigh 2kg of raw materials 3-methyl-3-butene-1-ol, 3kg of methanol, and 20g of sodium methoxide; mix the three materials evenly, pressurize the reaction tube to 10mpa with methanol, start feeding, and use a plunger for the mixture. Pump feeding, flow rate: 50g / h, control the reaction temperature to 170℃, control the reaction pressure to 10mpa, collect the reaction liquid, the raw material conversion rate: 42%, the selectivity of the main product is more than 90%; the obtained reaction liquid is rectified to obtain isoprene Enol, the product purity is greater than 99%.

Embodiment 2

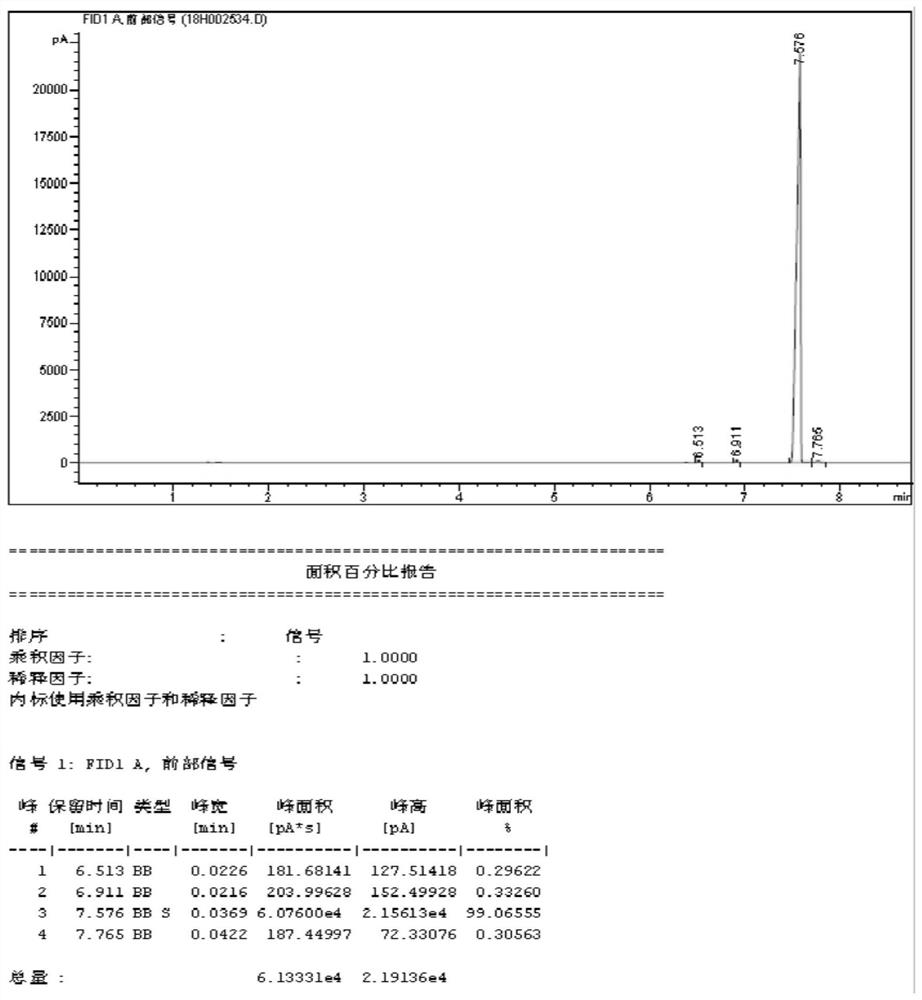

[0024] Weigh 2kg of raw materials 3-methyl-3-butene-1-ol, 4kg of methanol, and 40g of sodium methoxide; mix the three materials evenly, pressurize the reaction tube to 12mpa with methanol, start feeding, and use a plunger for the mixture. Pump feeding, flow rate: 70g / h, control the reaction temperature to 190℃, control the reaction pressure to 12mpa, the reaction liquid is collected, the raw material conversion rate: 45%, the selectivity of the main product is more than 90%; the obtained reaction liquid is rectified to obtain isoprene Enol, the product purity is greater than 99%.

Embodiment 3

[0026] Weigh 2kg of raw materials 3-methyl-3-butene-1-ol, 3kg of acetonitrile, and 40g of sodium methoxide; mix the three materials evenly, pressurize the reaction tube to 10mpa with methanol, start feeding, and use a plunger for the mixture. Pump feeding, flow rate: 70g / h, control the reaction temperature to 190℃, control the reaction pressure to 10mpa, the reaction liquid is collected, the raw material conversion rate: 44%, the selectivity of the main product is more than 90%; the obtained reaction liquid is rectified to obtain isoprene Enol, the product purity is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com