Coal mill

A technology of coal mills and grinding discs, applied in cocoa, grain processing, food science, etc., can solve problems such as large ventilation resistance, high grinding efficiency, complex structure, etc., to meet production needs, good extrusion effect, and feed in place effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

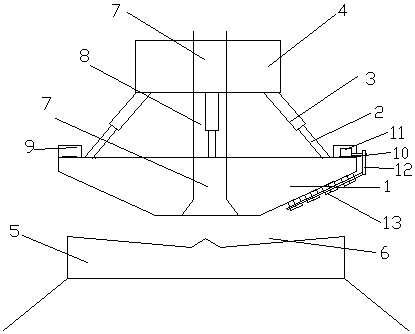

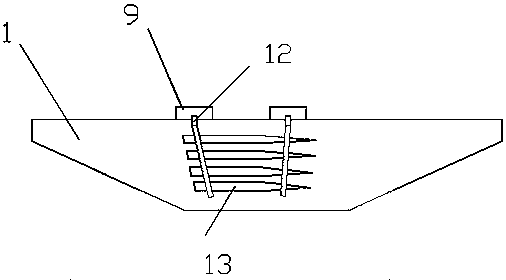

[0012] The figure shows an embodiment of the coal mill of the present invention, including a coal mill top cover, an upper millstone, a lower pressure plate 5, and a coal mill chassis. The upper millstone is movably connected to the coal mill top cover, and the lower pressure plate Set on the chassis of the coal mill, the upper grinding plate includes an upper platen 1, a hydraulic telescopic rod 2 connected to the upper platen, a hydraulic telescopic machine 3 and a controller 4, and the upper platen is rounded. There are multiple telescopic rods, which are equidistantly arranged on the top of the upper platen and connected to the hydraulic expansion machine, which is connected to the controller, and a scraping device is arranged on the outer side of the upper platen; the circular table of the lower platen is set , the upper surface of the circular table is set by a groove 6 that is gradually sunken outward toward the central area.

[0013] The center of the upper platen and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com