Trickle bed reactor

A reactor and trickle bed technology, applied in the field of fixed bed reactors, can solve the problems of long time consumption, increased production cost, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

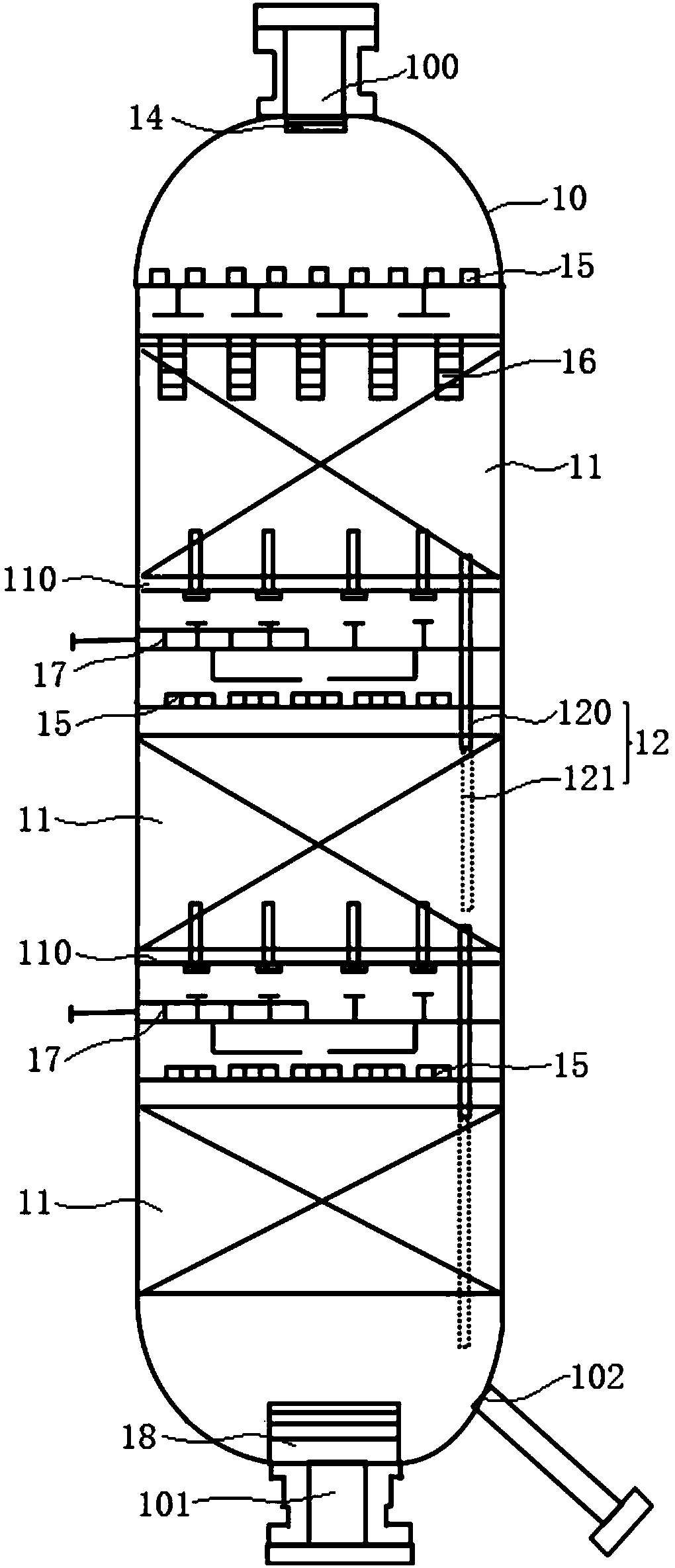

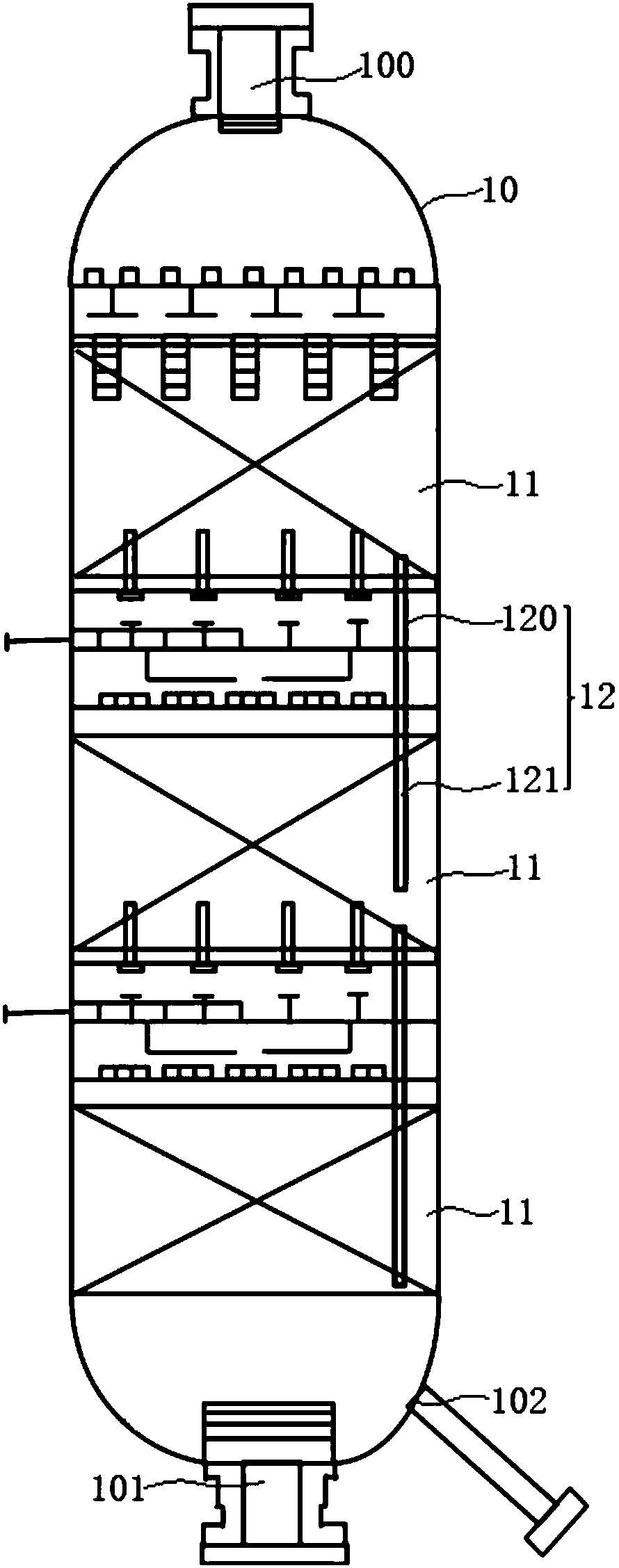

Embodiment 1

[0059] After the trickle bed reactor completes a reaction cycle, gradually reduce the input amount of raw material, and also pass into naphtha in the described trickle bed reactor, afterward, nitrogen is passed in the trickle bed reactor, Then the discharge port 102 is opened to discharge the catalysts in each bed 11 in sequence. Wherein, the configuration in the trickle bed reactor is as follows:

[0060] The reactor shell 10 provided with the feed port 100, the discharge port 101 and the discharge port 102 is roughly cylindrical, and the inner diameter of the reactor shell 10 is 2438mm, and three beds 11 are arranged in the reactor shell 10. The top is the first bed, the second bed and the third bed, in which:

[0061] The headroom height of the first bed is 5300mm, and the height of the upper part of the first bed is 300mm. The first bed is provided with a ceramic ball layer with a thickness of 200mm from top to bottom (the ceramic ball layer is filled with a diameter of 1...

Embodiment 2

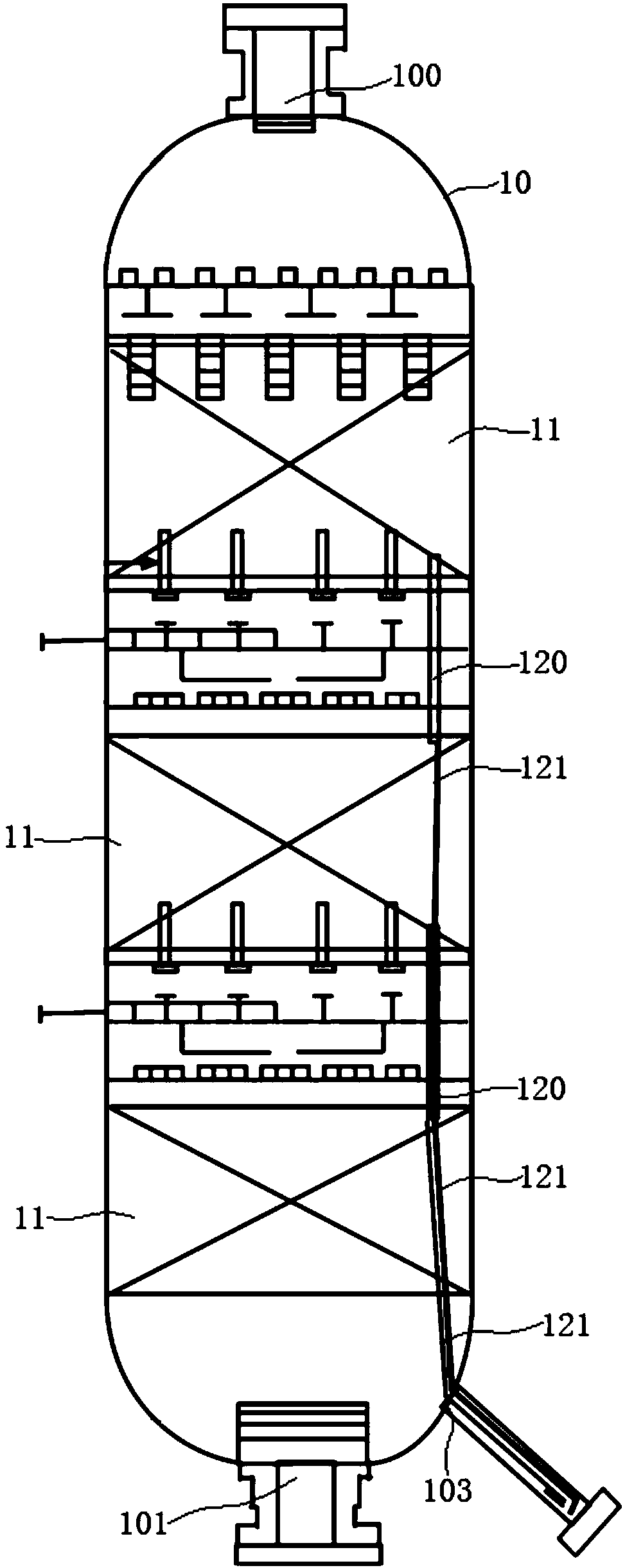

[0067] Select the same trickle bed reactor as in Example 1, wherein the extension pipe section 121 of each discharge pipe 12 is a carbon fiber cloth bag with open ends at both ends, and the rest of the configuration conditions are the same, and the same method as in Example 1 is selected. The catalyst in each bed 11 is unloaded.

Embodiment 3

[0069] Select the trickle bed reactor identical with embodiment 1, and the opening and closing unit 13 is set at the bottom port of the extension pipe section 121 of each discharge pipe 12, wherein, the opening and closing unit 13 is to have the preferred structure provided by the present invention (i.e. Figure 5 The opening and closing unit 13 of the structure shown in ), the rest of the configuration conditions are the same, and the catalyst in each bed 11 is unloaded in the same way as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com