Polyethylene compositions and articles made therefrom

A kind of composition, polymer technology, applied in the field of polyethylene composition and products made therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

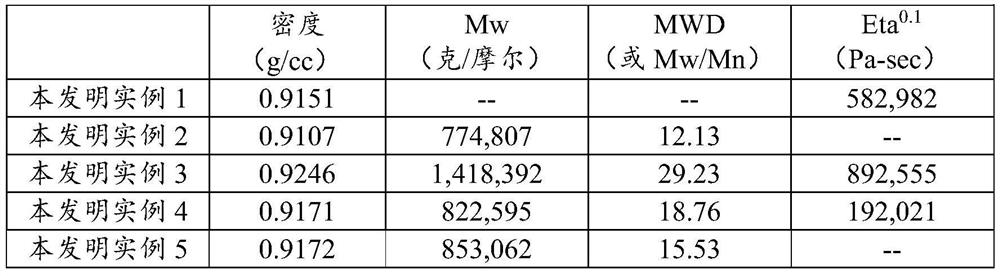

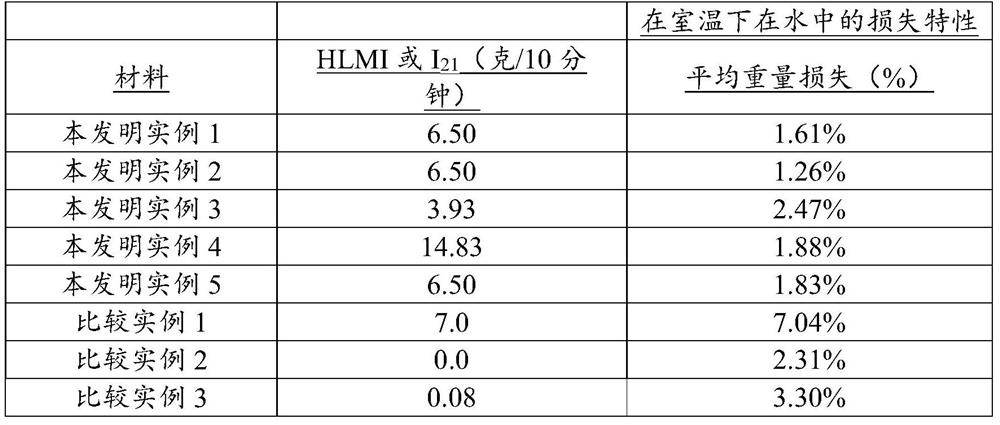

[0120] The following compositions were used in the examples described below.

example 1

[0122] Ultra-high molecular weight ethylene-based polymer (UTEC) with a weight average molecular weight of 8,000,000 g / mol, a density of 0.925 g / cc, an intrinsic viscosity of 28 dL / g, and an average particle size D50 of 150 μm TM 6541, available from Brasco, Brazil); polyethylene resin comprising a first molecular weight ethylene polymer component and a second molecular weight ethylene polymer component (DGDA-2420NT, density = 0.940 g / cc, high Load Melt Index I 21 =9.5g / 10min, melt index I2 of 0.15g / 10min, and Mw / Mn of 9, available from The Dow Chemical Company, USA); and thermoplastic polyolefin elastomer (INFUSE TM 9010, density = 0.877 g / cc, melt index I2 = 0.5 g / 10min, Mw / Mn of 2.6, available from The Dow Chemical Company, USA) was blended in a weight ratio of 50:15:35 to form a composition. The composition was mixed with 600 ppm of a fluoropolymer processing aid (melt flow index (265°C, 5 kg) of 10 g / 10 min (Dynamar) using a LabTech 26 mm twin screw compounder at the f...

example 2

[0128] Ultra-high molecular weight ethylene-based polymer (UTEC) with a weight average molecular weight of 8,000,000 g / mol, a density of 0.925 g / cc, an intrinsic viscosity of 28 dL / g, and an average particle size D50 of 150 μm TM 6541, available from Brasco, Brazil); polyethylene resin comprising a first molecular weight ethylene polymer component and a second molecular weight ethylene polymer component (DGDA-2420NT, density = 0.940 g / cc, high Load Melt Index I 21 =9.5g / 10min, melt index I2 is 0.15g / 10min, and Mw / Mn is 9, available from Dow Chemical Company, USA); and thermoplastic polyolefin elastomer (ENGAGE TM 7387, density=0.870 g / cc, melt index I2=0.5 g / 10min, available from The Dow Chemical Company, USA) was blended in a weight ratio of 50:15:35 to form a composition. The composition was mixed with 600 ppm of a fluoropolymer processing aid (melt flow index (265°C, 5 kg) of 10 g / 10 min (Dynamar FX5911, available from Available from 3M Company in the United States)) co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com