A smooth modeling method for a centrifugal pump volute

A centrifugal pump and volute technology, which is applied in the field of UGNX-based centrifugal pump volute smoothing modeling, can solve problems such as modeling distortion and surface connection is not smooth, and achieve the effect of natural surface transition, improve modeling quality, and reduce modeling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

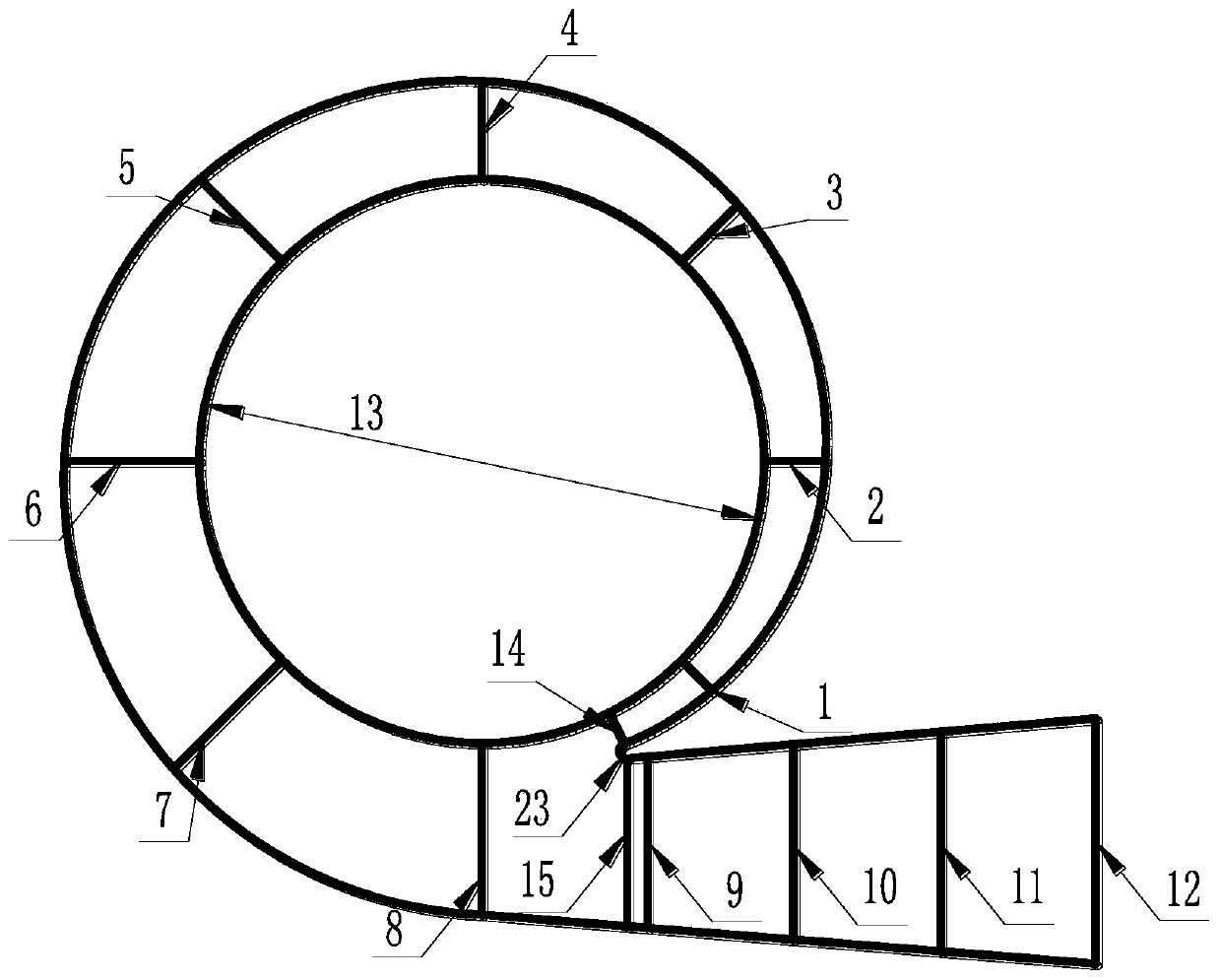

[0101] Carry out modeling according to the complete smooth molding method of the centrifugal pump volute:

[0102] a. Draw the three-dimensional sketches of the spiral part and the diffuser part of the centrifugal pump volute respectively.

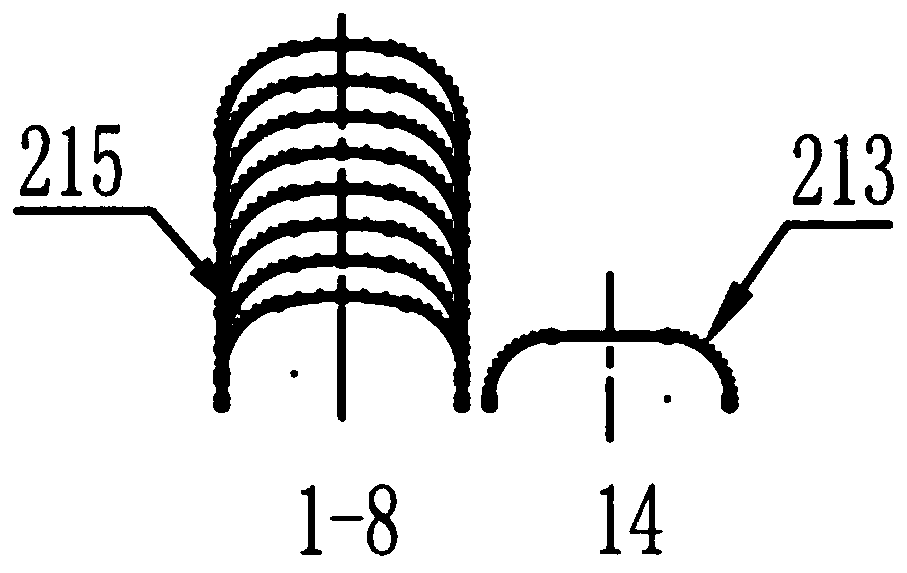

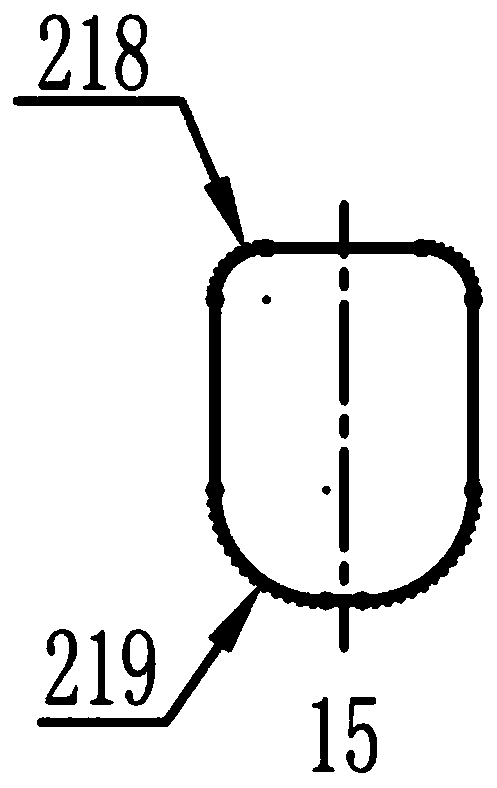

[0103] Wherein, the radius of the tongue-separating arc 23 is 3 mm. The radius of the fourteenth upper corner arc 213 of the fourteenth section 14 is 13 mm; the radius of the first upper corner arc 215 of the first section 1 is 15 mm. The radius of the fifteenth upper corner arc 218 of the fifteenth section 15 and the ninth upper corner arc 210 of the ninth section 9 are both 10mm; the radius of the fifteenth lower corner arc 219 of the fifteenth section 15 is 21.5mm , the radius of the ninth lower corner arc 222 of the ninth section 9 is 22 mm.

[0104] b. Generate the 3D surface of the spiral part and the diffuser part of the centrifugal pump volute.

[0105] c. Draw isoparametric curves and bridging curves to generate septum curved s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com