Forming process for V-shaped composite material part with thickened bottom of training plane

A composite material and molding process technology, applied in household components, other household appliances, household appliances, etc., can solve the problems of high cost and the difficulty of forming V-shaped composite material parts with thickened bottom, achieve broad promotion value and reduce molding costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

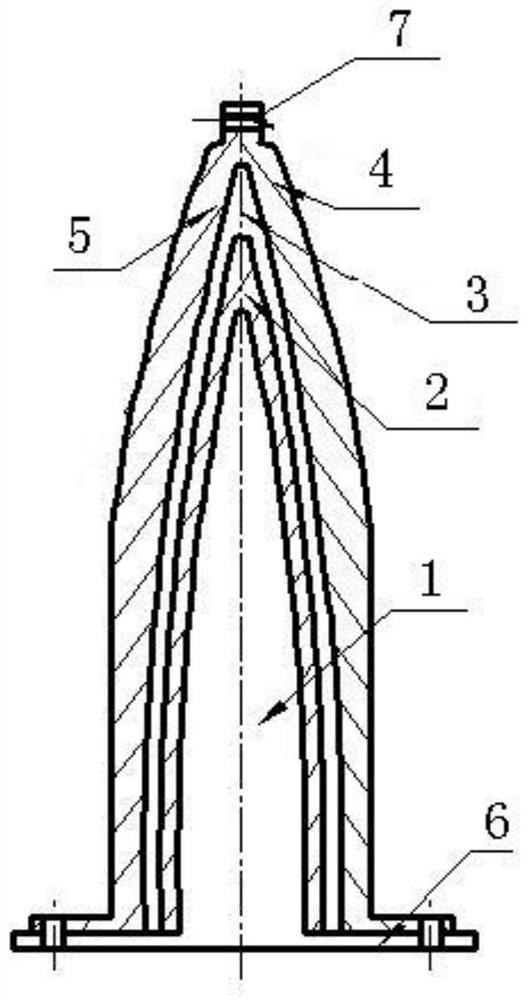

[0012] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0013] The molding process of the thickened V-shaped composite material parts at the bottom of the trainer includes the following steps:

[0014] (1) Clean up the formed silicone soft mold 2 and install it on the metal male mold 1 of the part to form a combined male mold;

[0015] (2) Spread release cloth or brush release agent on the combined male mold, then spread fiber cloth, vacuumize for exhaust and pre-compact every time 3 to 5 layers of fiber cloth are laid, until the laying reaches Desired thickness, forming a pre-composite material preform 3;

[0016] (3) Combine the demoulding-processed female mold 1 4 and female mold 2 5 and fasten them on the outer surface of the composite material prefabricated part 3 , the top is assembled in place with fixed connecting bolts, and the bottom is fixed on the base 6 of the metal male mold 1 with bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com