Reference mode programmer assistant method and device

A benchmark and program technology, applied in the field of programming assistance, can solve problems such as low efficiency, cumbersome operation process, and failure to meet the efficiency and cost requirements of benchmark models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0115] Such as figure 1 As shown, the embodiment of the present invention provides a reference model programmer assistance method, including 3D model generation step S1, sketch extension step S2, curve projection step S3, fine grain slice processing step S4, operation transformation step S5, operation modification step One or more of S6, circumferential transformation step S7, automatic operation generation step S8, pitch splicing step S9, pore mark making step S10, material program generation step S11, template program generation step S12, modeling tool preparation step S13 .

[0116] The 3D model generating step S1 includes: receiving the curve-related parameters of the XY plane entered by the user, and automatically realizing the generation of 3D sheet or solid model by applying the material entity program and tread creation program of NX software. The function of generating 3D modeling from the 2D curve of the tire section is realized by the two-part program of "material ...

specific Embodiment 2

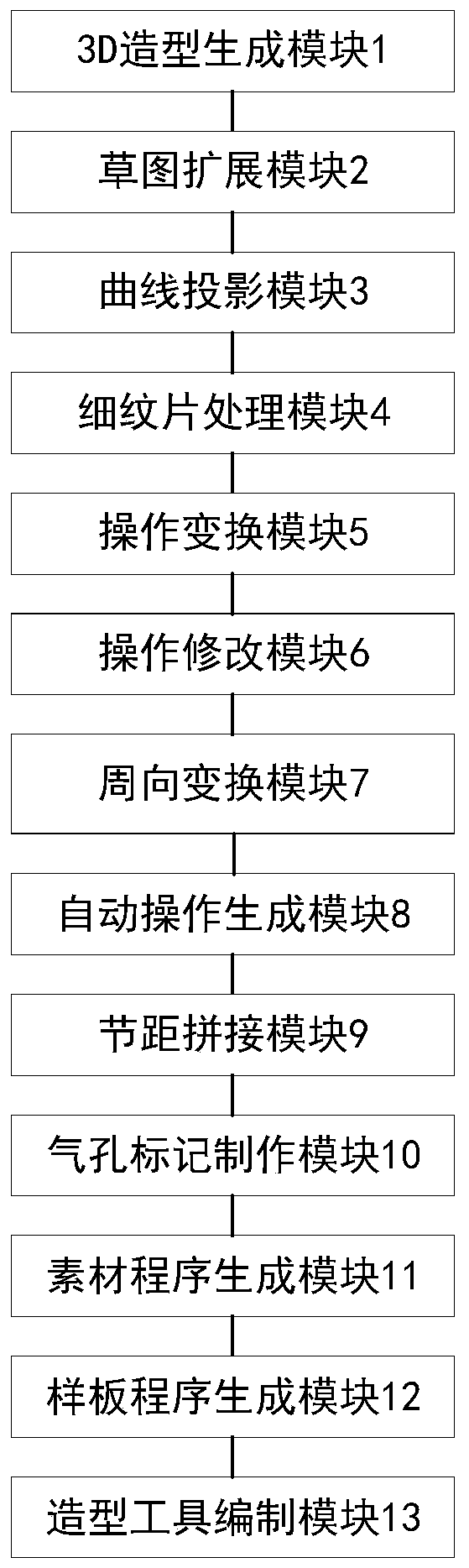

[0154] Such as figure 2 As shown, the embodiment of the present invention provides an auxiliary device for programmers of reference models, including a 3D model generation module 1, a sketch expansion module 2, a curve projection module 3, a fine grain slice processing module 4, an operation conversion module 5, and an operation modification module 6. One or more of the circumferential transformation module 7, the automatic operation generation module 8, the pitch splicing module 9, the pore mark production module 10, the material program generation module 11, the template program generation module 12, and the modeling tool preparation module 13 ;in,

[0155] The 3D modeling generation module 1 is used for:

[0156] Receive the curve-related parameters of the XY plane entered by the user, and automatically realize the generation of 3D sheet or solid shape through the material entity program and tread creation program applied to NX software;

[0157] The Sketch Extension Mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com