Wall-type component lateral support device and low cycle repeated loading test device

A technology of lateral support and test equipment, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc. It can solve problems such as eccentricity and torsion, large errors in test data, and deformation of structures under stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

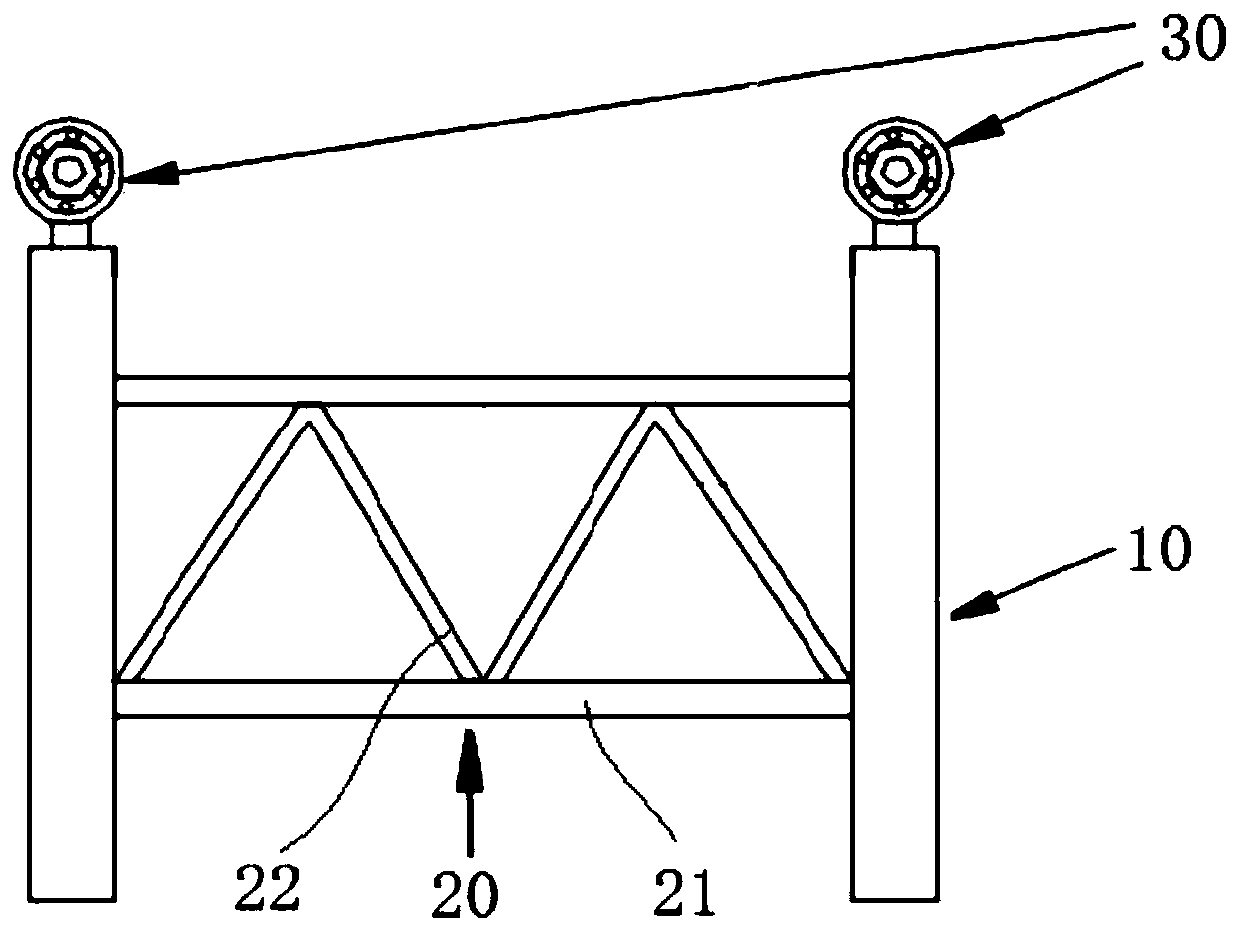

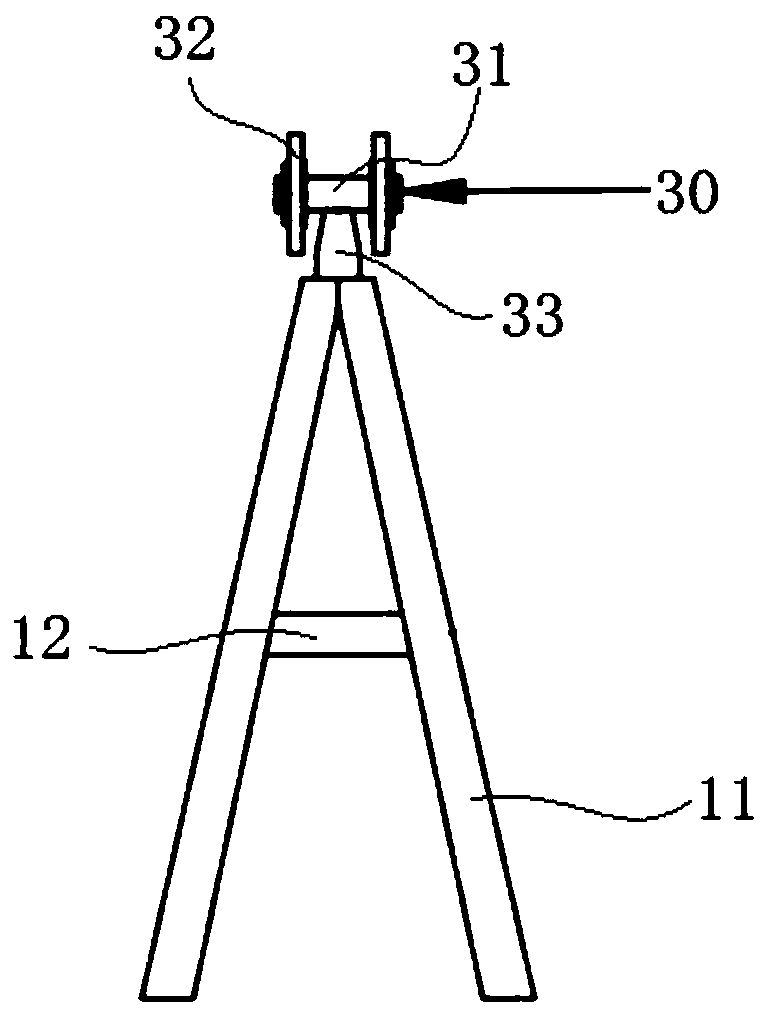

[0034] refer to Figure 1 to Figure 3 , the present embodiment provides a lateral support device for a wall structure, which includes at least one connecting bracket 20 , a pair of lateral supports 10 and two sets of pulleys 30 .

[0035] One end of each lateral support body 10 is perpendicular to its length direction and is provided with pulley block 30, and described pulley block 30 can press against the surface of the wall type component to be tested and can apply vertical or horizontal force to the wall type component to be tested in the loading device Rotate downward, the other end of the lateral support 10 is a free end, which can be embedded in the lateral support beam in the low cycle repeated loading test device.

[0036] In this embodiment, the lateral support body 10 includes two pillars A11 and a connecting pillar 12, the pillars A11 and the connecting pillar 12 form an A-shaped lateral supporting body, between the two pillars A11, the pillar A11 Both are connecte...

Embodiment 2

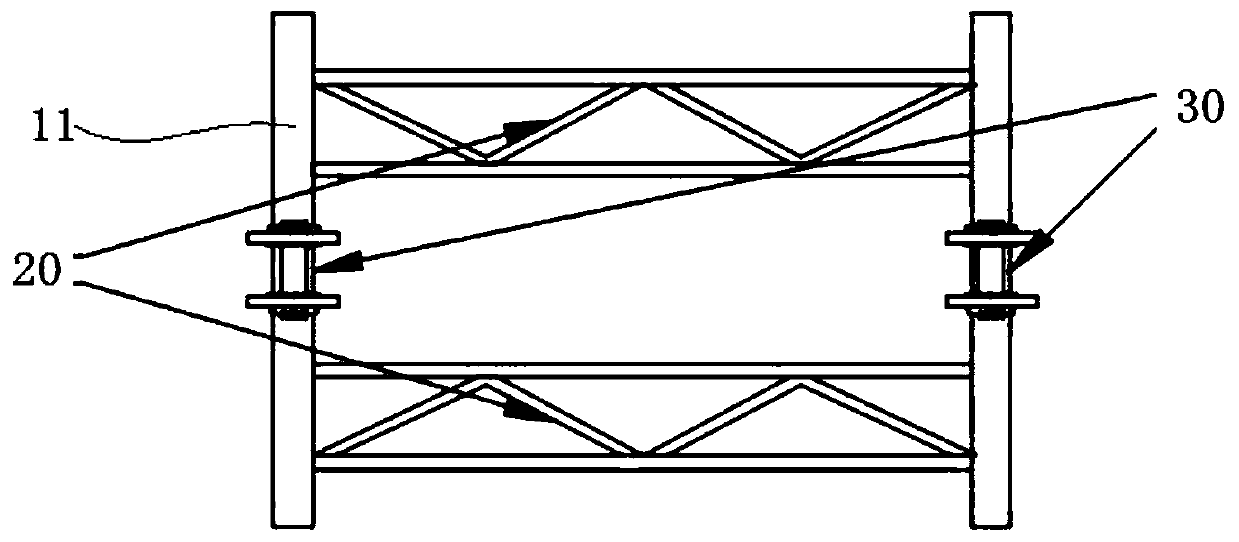

[0043] Such as Figure 4 and Figure 5 As shown, this embodiment provides a low-cycle repeated loading test device suitable for wall components, which includes a reaction force frame 40 and at least two Lateral support beams 60 .

[0044]Wherein, the reaction force frame 40 is built with a wall member 50 to be tested, and is equipped with a vertical load loading device 71 and a horizontal load loading device 72 . The lateral support beam 60 is installed symmetrically on both sides of the wall member 50 to be tested; The test wall member 50 rotates under a vertical or horizontal force, and the free end of the lateral support 10 is embedded in the lateral support beam 60 .

[0045] In this embodiment, the lateral support beam 60 is I-shaped steel, and the free end of the lateral support body 10 is embedded in the inner surface of the groove body of the lateral support beam 60, so that the lateral support body 10 can be stressed more stable and reliable.

[0046] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com