Liquefied gas loading and unloading position spraying device

A spray device, liquefied gas technology, applied in gas/liquid distribution and storage, container discharge method, container filling method, etc. The effect of safety, smooth and safe loading and unloading, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

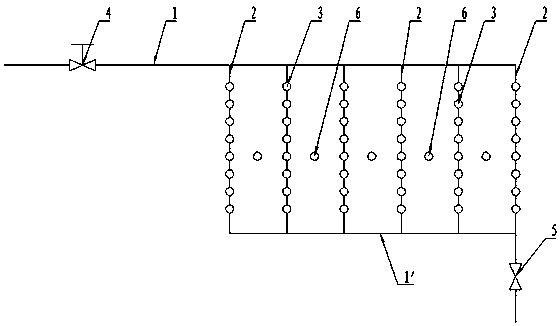

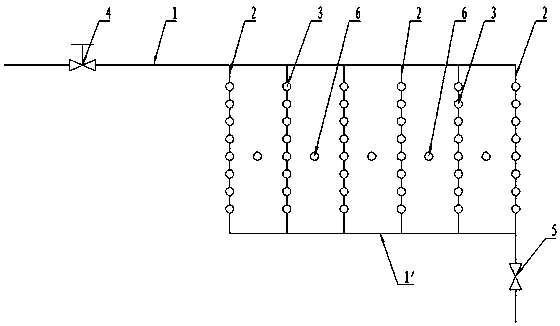

[0010] The novel liquefied gas loading and unloading parking space spray device of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0011] Depend on figure 1 It can be seen that the liquefied gas loading and unloading parking space spray device of the present invention includes upper and lower fire-fighting pipes 1, 1', and several vertical fire-fighting pipes 2 are arranged between the upper and lower fire-fighting pipes 1, 1', each The vertical fire-fighting pipeline 2 is provided with a plurality of spray nozzles 3; one end of the upper fire-fighting pipeline 1 is provided with a spray shut-off valve 4, and one end of the last vertical fire-fighting pipeline 2 is provided with a drain valve 5; A combustible gas alarm 6 is provided below each vertical fire-fighting pipeline 2.

[0012] see figure 1 , when the present invention is working, the present invention is installed above the loading and unloading parking spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com