Tunnel lining concrete pouring quality control method and device

A quality control method, concrete technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., to achieve the effect of avoiding insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a method for controlling the quality of tunnel lining concrete pouring, which can strictly control the lining concrete pouring process during the construction process, effectively avoiding insufficient strength, segregation, accumulation of aggregates, insufficient lining thickness, voids, cracks, etc. Quality issues include: methods to prevent concrete defects, methods to prevent concrete vault cavities, methods to protect end forms, methods to prevent over-vibration and displacement of trolleys, and methods to protect against overloads of trolleys.

[0060] Wherein, the method for preventing concrete defects specifically includes:

[0061] When the concrete pump truck 3 is turned on for lining concrete pouring, the trolley form composite sensor 27 is turned on at the same time; when the concrete contacts the pressure sensor in the trolley form composite sensor 27, the pressure sensor in the trolley form composite sensor 27 generates pressure Signal...

Embodiment 2

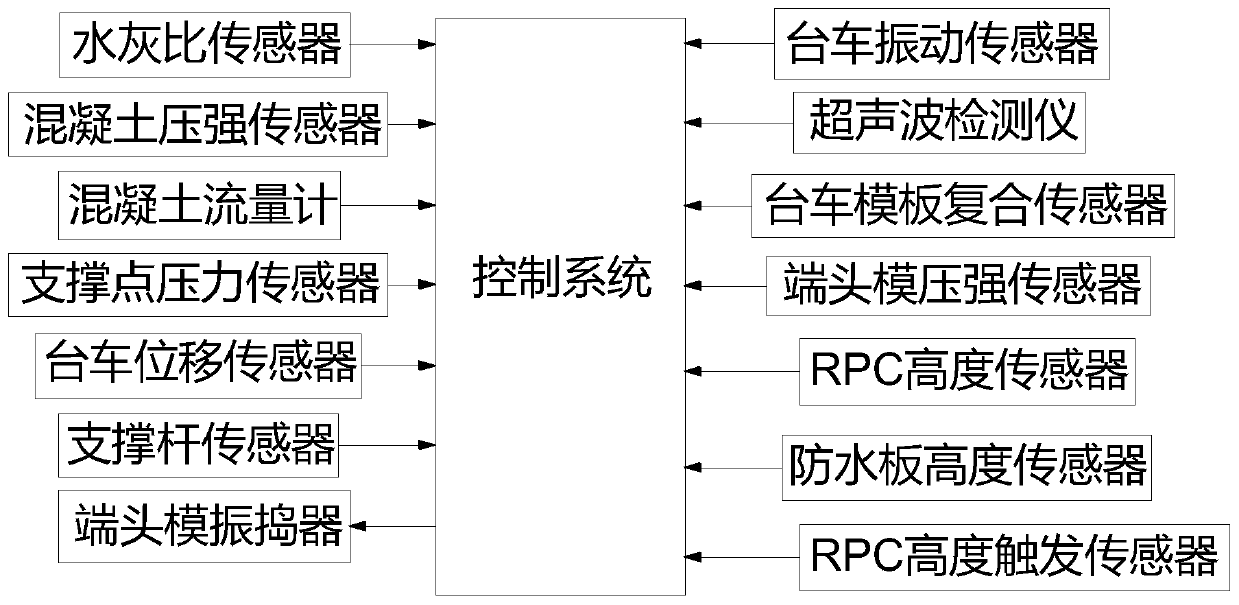

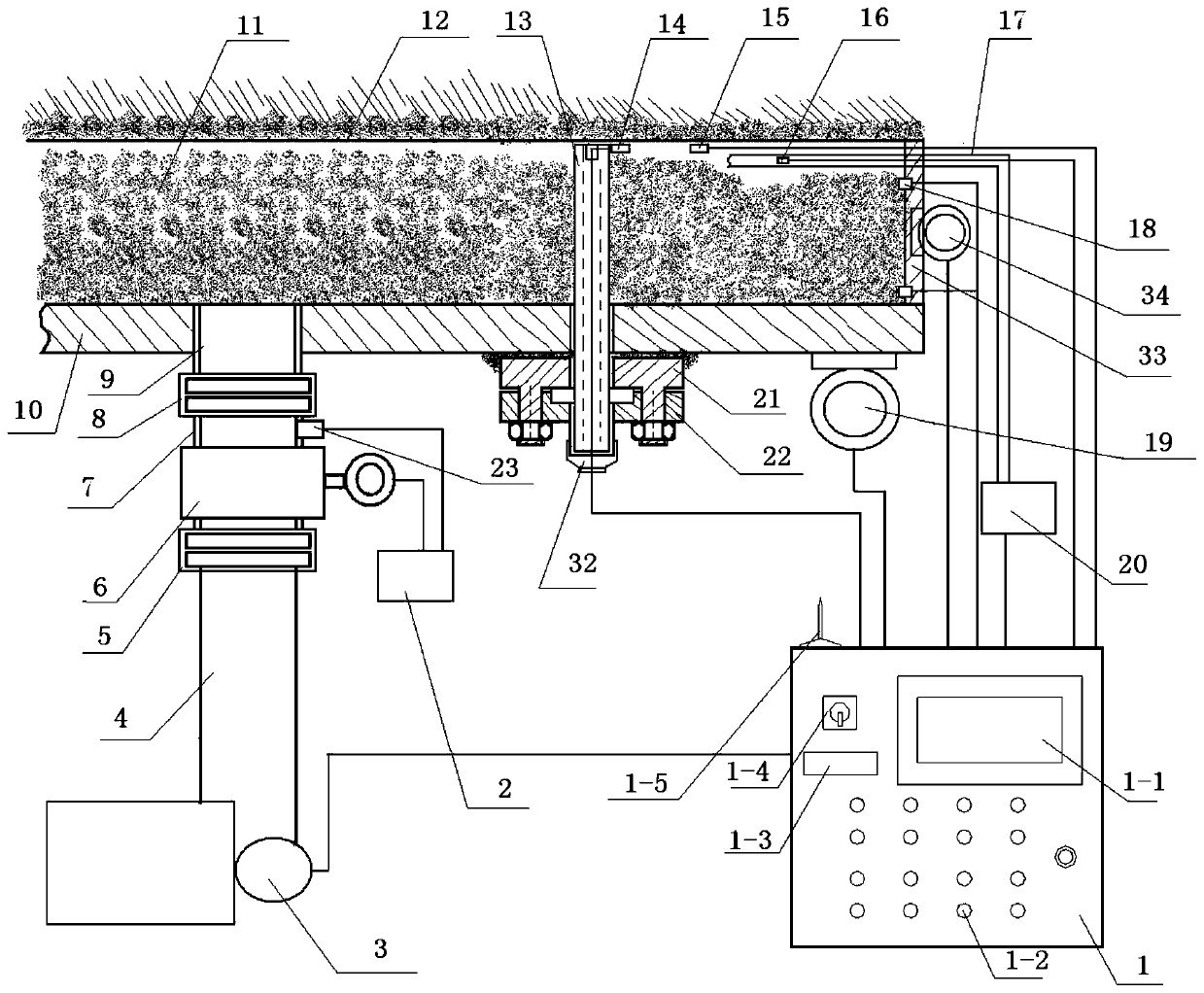

[0086] This embodiment provides a tunnel lining concrete pouring quality control device, which includes a height sensor, a water-cement ratio sensor, an end mold pressure sensor, a concrete pressure sensor, a concrete flow meter, a trolley vibration sensor, a trolley displacement sensor, and a platform Vehicle template composite sensor, support rod sensor, support point pressure sensor and control system.

[0087] The height sensor signal is connected to the controller of the control system for detecting the real-time height of concrete and sending the real-time height data of concrete to the controller of the control system; in this embodiment, the height sensor includes RPC height sensor 14 and waterproof board height sensor 15. The RPC height sensor is installed on the top of the RPC grouting pipe for grouting with mold, and the waterproof board height sensor is installed on the surface of the waterproof board, so that when in use, the RPC injection The slurry pipe is inserted...

Embodiment 3

[0117] This embodiment provides a method for installing a lining concrete quality control device, which is used to install the lining concrete quality control device as described in Embodiment 2, and is performed according to the following steps:

[0118] (1) Move the trolley to the position where the lining concrete needs to be poured;

[0119] (2) Install the concrete detection tube 7 on the upper pump tube 9 connected with the trolley template 10 through the upper pump tube clamp 8, connect the concrete flow meter 6 and the concrete pressure sensor 23 to the concrete detection tube 7, and then launch The signal line of the device 2 is connected with the concrete flow meter 6 and the concrete pressure sensor 23, the lower pump pipe 4 is connected to the concrete detection pipe 7 through the lower pump pipe clamp 5, and the lower end of the lower pump pipe 4 is connected to the concrete pump truck 3 ;

[0120] (3) Fix the waterproof board height sensor 15 on the waterproof board 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com