Impeller type multi-pulse water power oscillator

A hydraulic oscillator and multi-pulse technology, used in vibration drilling, vibration generating devices, wellbore/well components, etc., can solve the problem of unsatisfactory use effect of axial vibration tools, inability to effectively transmit wellhead WOB, and carrying drilling fluids. The problem of low rock capacity, etc., can improve the rock-carrying capacity, increase the drilling speed, and reduce the consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

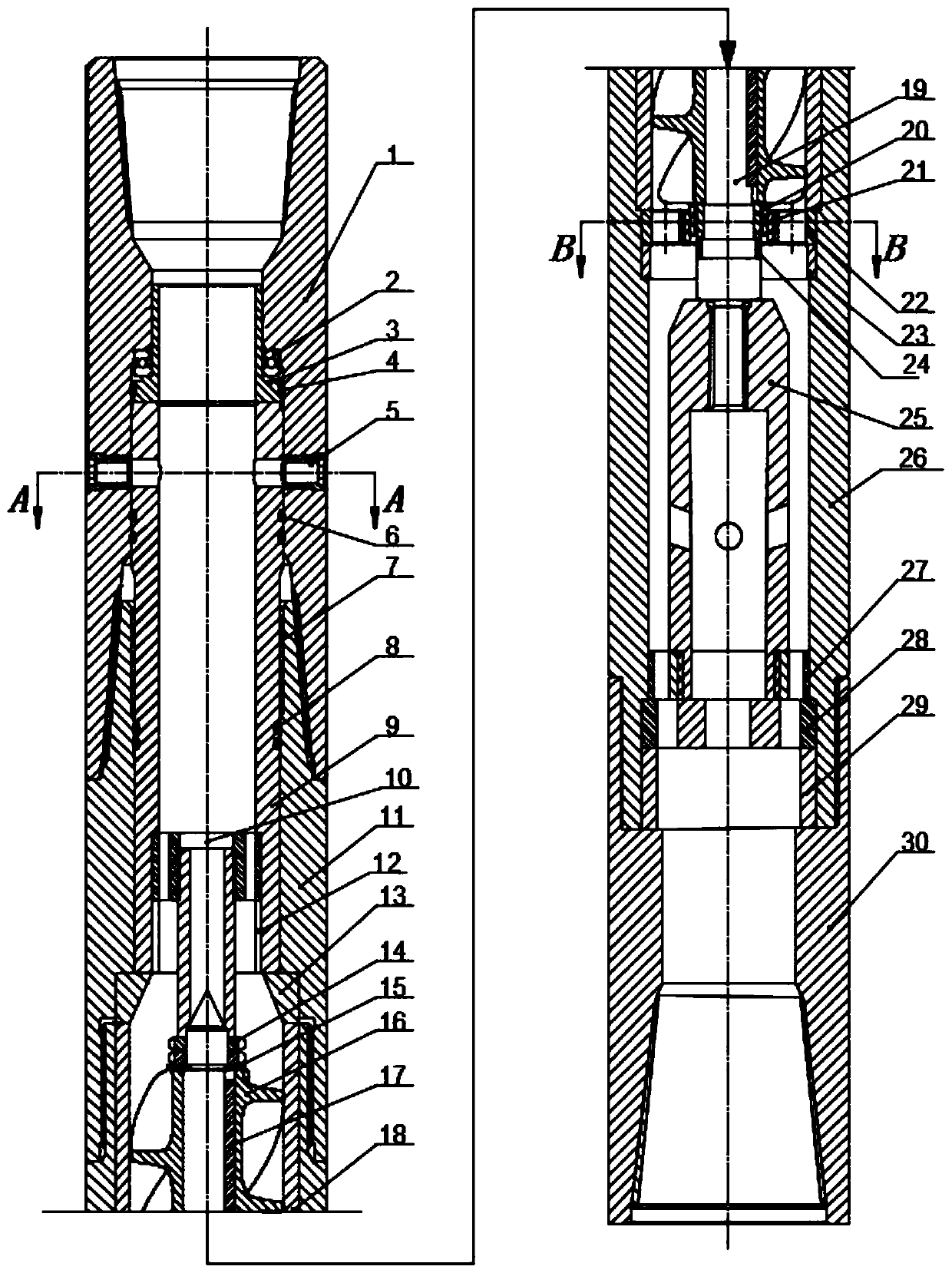

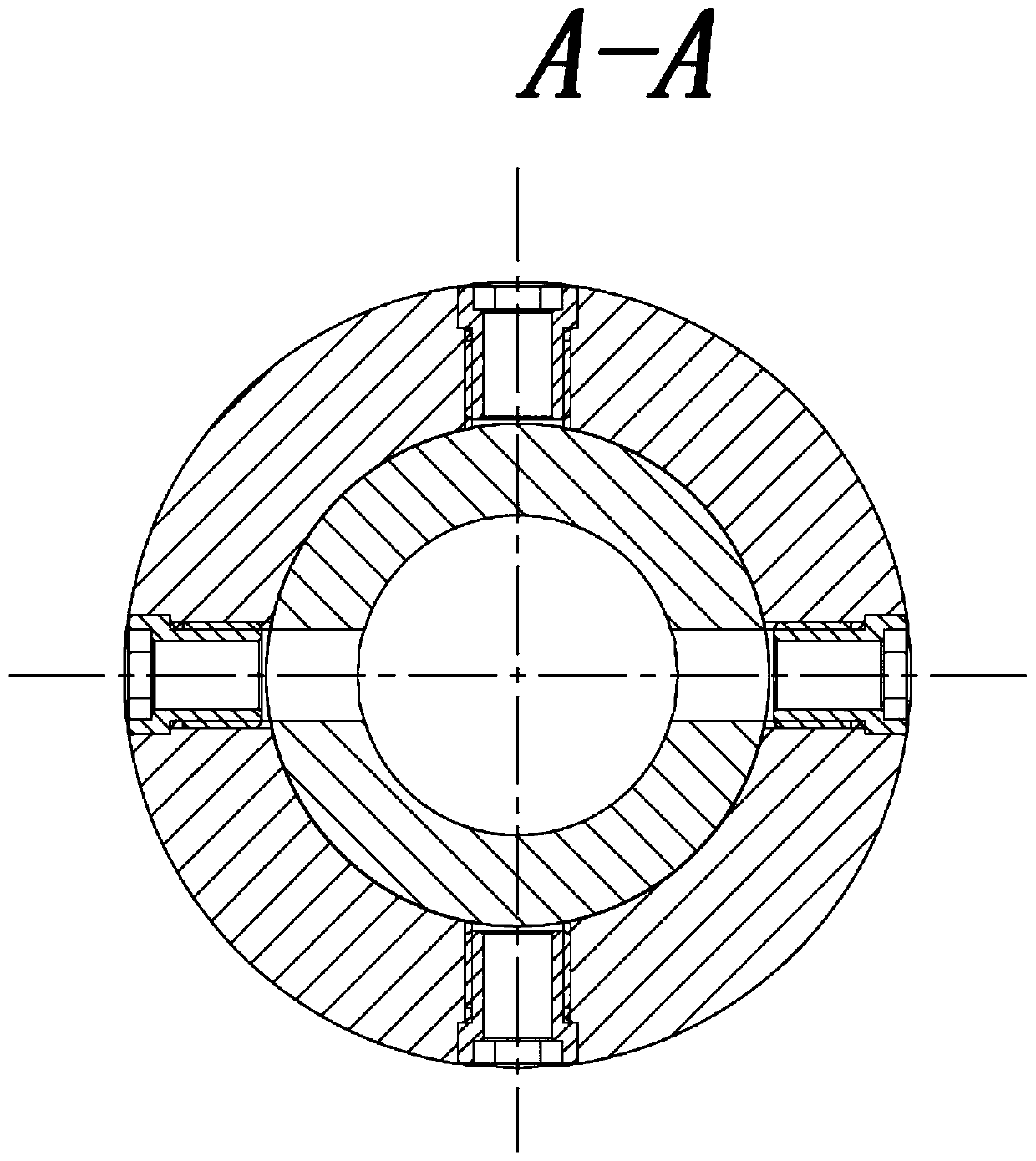

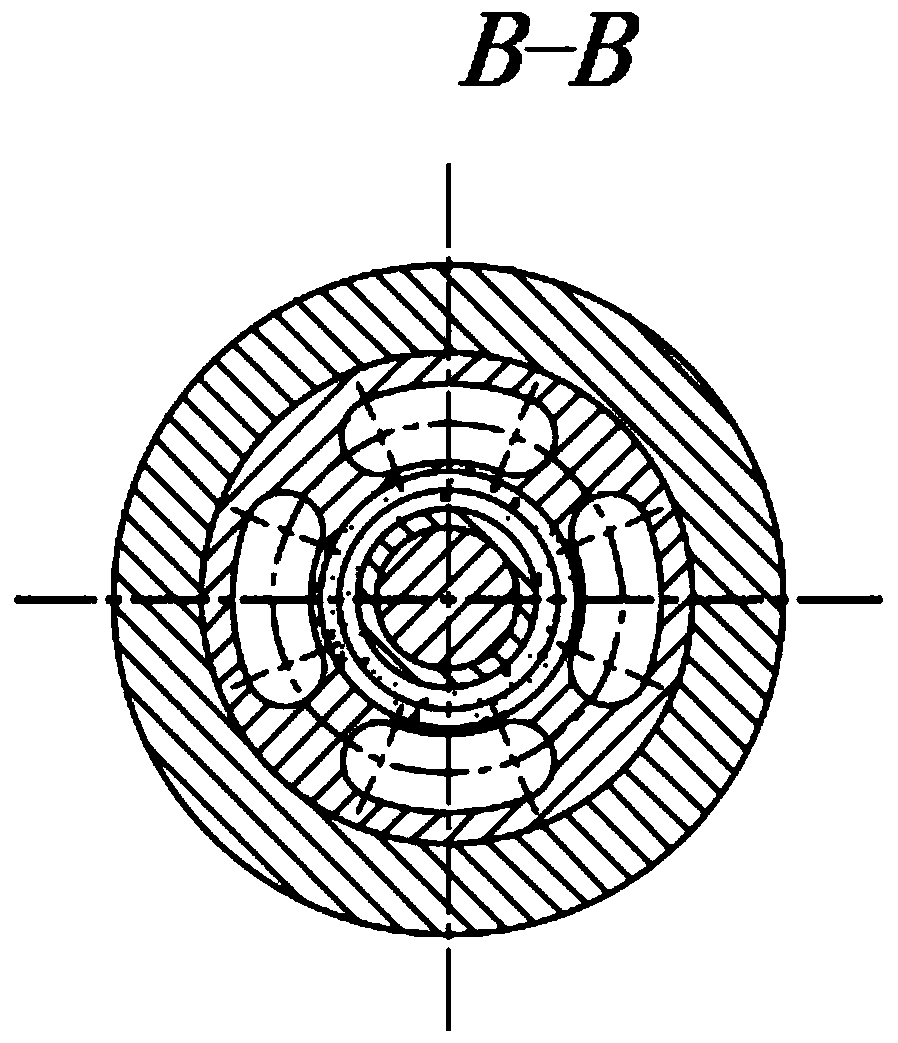

[0016] According to the drawings, the impeller-type multi-pulse hydraulic oscillator consists of an upper joint, a thrust bearing, a bearing stop ring, an O-ring A, a nozzle, an O-ring B, a wear-resistant bushing, and an O-ring C. Valve core, cylindrical connection block, flat key A, upper casing, guide sleeve, lock nut, gasket, impeller, flat key B, impeller sleeve, impeller shaft, positioning sleeve A, sliding bearing, The overflow plate, the support plate, the positioning sleeve B, the transmission nipple, the lower shell, the movable valve plate, the static valve plate, the sleeve, and the lower joint are characterized in that the upper joint 1, the upper shell 11, and the lower shell 26 and the lower joint 30 are sequentially connected by screw threads; the middle part of the upper joint 1 is provided with 4 radial through holes spaced 90° apart from each other, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com