Composite basalt fiber material and making method and application thereof

A technology of basalt fiber and production method, which is applied in the application, fiber processing, separation method and other directions, can solve the problems of high cost, hidden dangers, difficult production of microbial carriers, etc., and achieves low cost, simple production process, and increased antibacterial function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Pulverize the basalt, heat and melt it at a high temperature of 1450°C to form a high-temperature basalt solution;

[0028] (2) Add nano-zinc oxide with a volume ratio of 0.5% and a particle size of 40nm to the high-temperature basalt solution to form a high-temperature mixed basalt solution;

[0029] (3) High-temperature mixed basalt solution is drawn at high speed to form composite basalt fiber precursors;

[0030] (4) The composite basalt fiber precursors are subjected to surface modification treatment by precipitation reaction coating method in the environment of silica;

[0031] (5) Twisting the surface-modified composite basalt fiber precursors into a composite basalt fiber material.

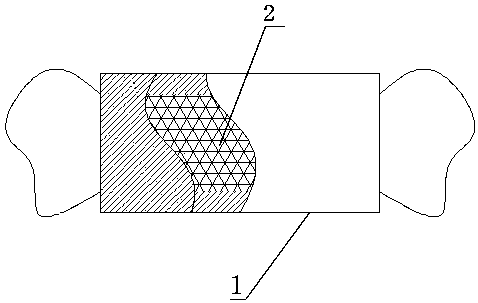

[0032] Such as figure 1 As shown, the composite basalt fiber material made by the above method is interlaced into basalt fiber cloth by warp and weft, the basalt fiber cloth is cut into a mask filter element 1 of suitable size, and the mask filter element 1 is placed in the ma...

Embodiment 2

[0034] (1) Pulverize the basalt, heat and melt at a high temperature of 1475°C to form a high-temperature basalt solution;

[0035] (2) Add nano-zinc oxide with a volume ratio of 1% and a particle size of 60nm to the high-temperature basalt solution to form a high-temperature mixed basalt solution;

[0036] (3) High-temperature mixed basalt solution is drawn at high speed to form composite basalt fiber precursors;

[0037] (4) The composite basalt fiber precursors are subjected to surface modification treatment by precipitation reaction coating method in the environment of silica;

[0038] (5) Twisting the surface-modified composite basalt fiber precursors into a composite basalt fiber material.

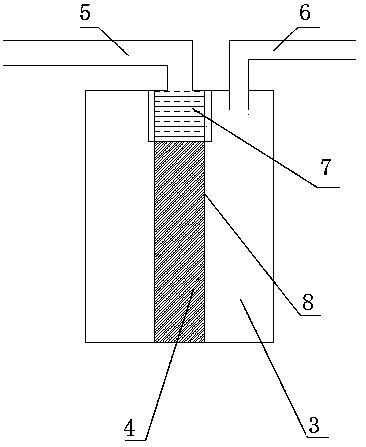

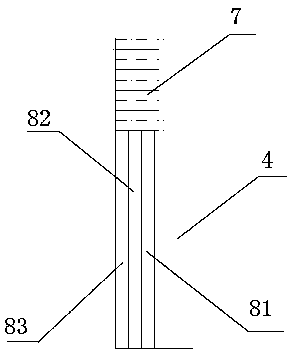

[0039] Such as figure 2 As shown, the composite basalt fiber material made by the above method is interlaced into a basalt fiber filter layer 83, and the PP cotton filter layer 81, activated carbon filter layer 82 and basalt fiber filter layer 83 are sequentially compounded from t...

Embodiment 3

[0041] (1) Pulverize the basalt, heat and melt it at a high temperature of 1500°C to form a high-temperature basalt solution;

[0042] (2) Add nano-zinc oxide with a volume ratio of 1.5% and a particle size of 80nm to the high-temperature basalt solution to form a high-temperature mixed basalt solution;

[0043] (3) High-temperature mixed basalt solution is drawn at high speed to form composite basalt fiber precursors;

[0044] (4) The composite basalt fiber precursors are subjected to surface modification treatment by precipitation reaction coating method in the environment of silica;

[0045] (5) Twisting the surface-modified composite basalt fiber precursors into a composite basalt fiber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com