Low-foam neutral water-based chain plate lubricant and preparation method thereof

A neutral water and lubricant technology, which is applied in lubricating compositions and the petroleum industry, etc., can solve the problems of poor lubricating effect, high foaming, low foaming, etc., and achieve good lubricating effect, good lubricating ability, high The effect of resistance to hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

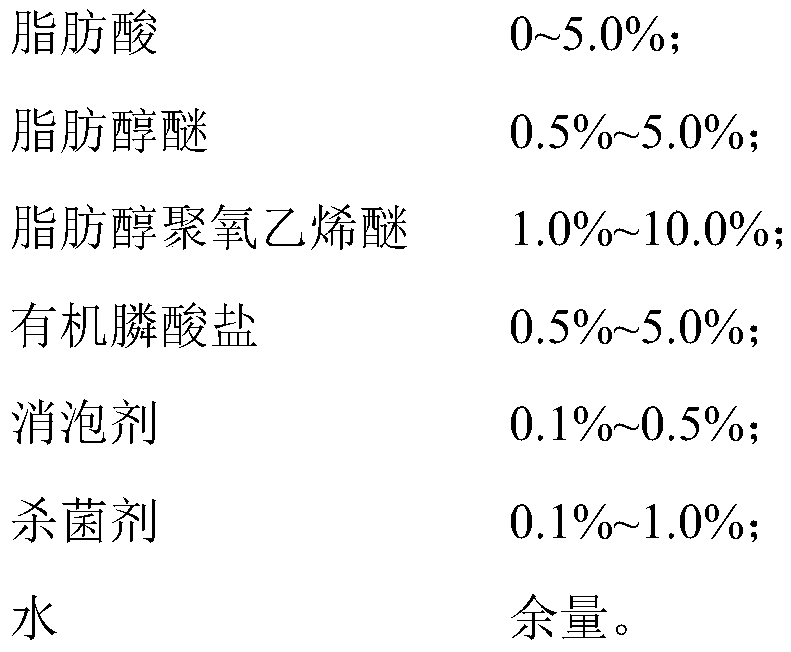

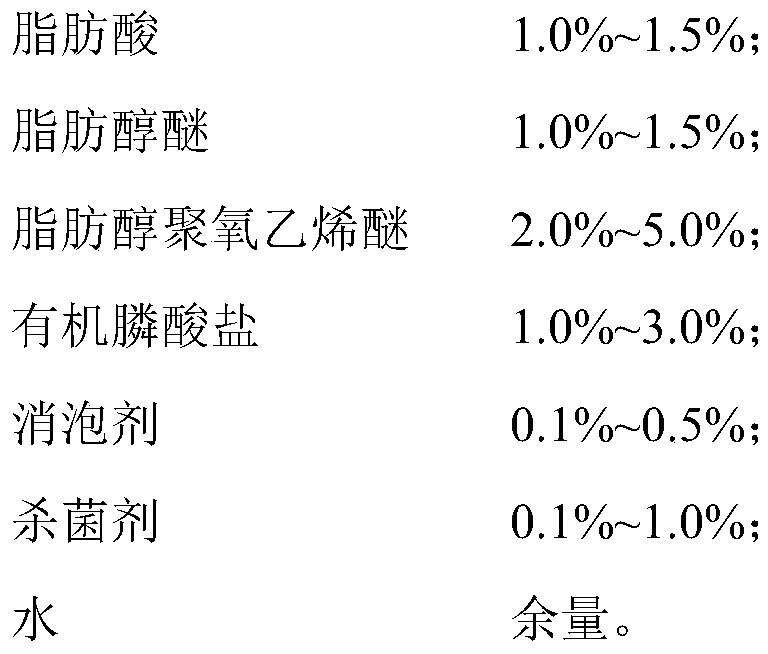

Method used

Image

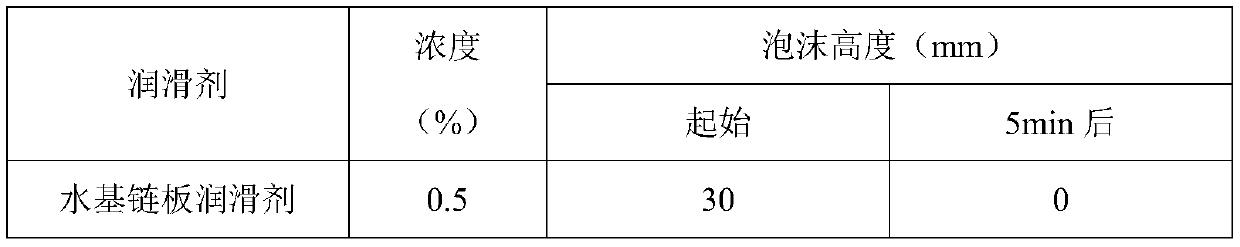

Examples

Embodiment 1

[0043] 1. Preparation of water-based chain plate lubricant

[0044] (1) Take 10g of cis-9-octadecenoic acid, 50g of isodecacarbonyl alcohol polyoxyethylene ether, 10g of dipropylene glycol methyl ether, 30g of ethylenediaminetetramethylenephosphonate sodium, respectively, and 200g of pure water will The above substances are evenly dispersed;

[0045] (2) add 5g bactericide and 3g defoamer wherein, stir;

[0046] (3) Make up the remaining amount of water until the total mass of the solution is 1000 g, stir evenly, and detect that the pH value of the solution is 7.02.

[0047] 2. Lubrication performance test of water-based chain plate lubricants

[0048] (1) The water-based chain plate lubricant prepared in Example 1 is diluted with pure water at a ratio of 1:125, and the diluted solution is evenly sprayed with a jet flow rate of 40ml / min to a running speed of 50cm / s. On the engineering plastic chain plate moving at a uniform speed, the tensile force of the stationary vessel ...

Embodiment 2

[0052] 1. Preparation of water-based chain plate lubricant

[0053] (1) respectively get 50g isodecacarbonyl alcohol polyoxyethylene ether, 10g dipropylene glycol methyl ether, 30g sodium ethylenediamine tetramethylene phosphonate, and disperse the above substances uniformly with the pure water of 200g;

[0054] (2) add 5g bactericide and 3g defoamer wherein, stir;

[0055] (3) Make up the remaining amount of water until the total mass of the solution is 1000 g, stir evenly, and detect that the pH value of the solution is 7.56.

[0056] The water-based linker lubricant component of Example 2 contains no fatty acids; the water-based linker lubricant combination of Example 1 contains fatty acids.

[0057] 2. Lubrication performance test of water-based chain plate lubricants

[0058] (1) The water-based chain plate lubricant prepared in Example 2 is diluted with pure water at a ratio of 1:125, and the diluted solution is evenly sprayed with a jet flow rate of 40ml / min to a runn...

Embodiment 3

[0062] 1. Preparation of water-based chain plate lubricant

[0063] (1) Take 10g of 12-hydroxy-cis-9-octadecenoic acid, 50g of isodecacarbonyl alcohol polyoxyethylene ether, 10g of dipropylene glycol methyl ether, 30g of ethylenediaminetetramethylenephosphonate sodium respectively, and use 200g of pure water will disperse the above substances evenly;

[0064] (2) add 5g bactericide and 3g defoamer wherein, stir;

[0065] (3) Make up the remaining amount of water until the total mass of the solution is 1000 g, stir evenly, and detect that the pH value of the solution is 7.15.

[0066] The fatty acid contained in the water-based chain plate lubricant component in Example 3 is 12-hydroxy-cis-9-octadecenoic acid; the fatty acid contained in the water-based chain plate lubricant component in Example 1 is cis- 9-octadecenoic acid.

[0067] 2. Lubrication performance test of water-based chain plate lubricants

[0068] (1) The water-based chain plate lubricant prepared in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com