Printing method and device, printer and storage medium

A technology of printing dots and printing drive, applied in printing devices, printing and other directions, can solve the problems of insufficient image dots, large instantaneous current of printing demand, large peak current, etc., and achieve the effect of reducing the uniform distribution of heating pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

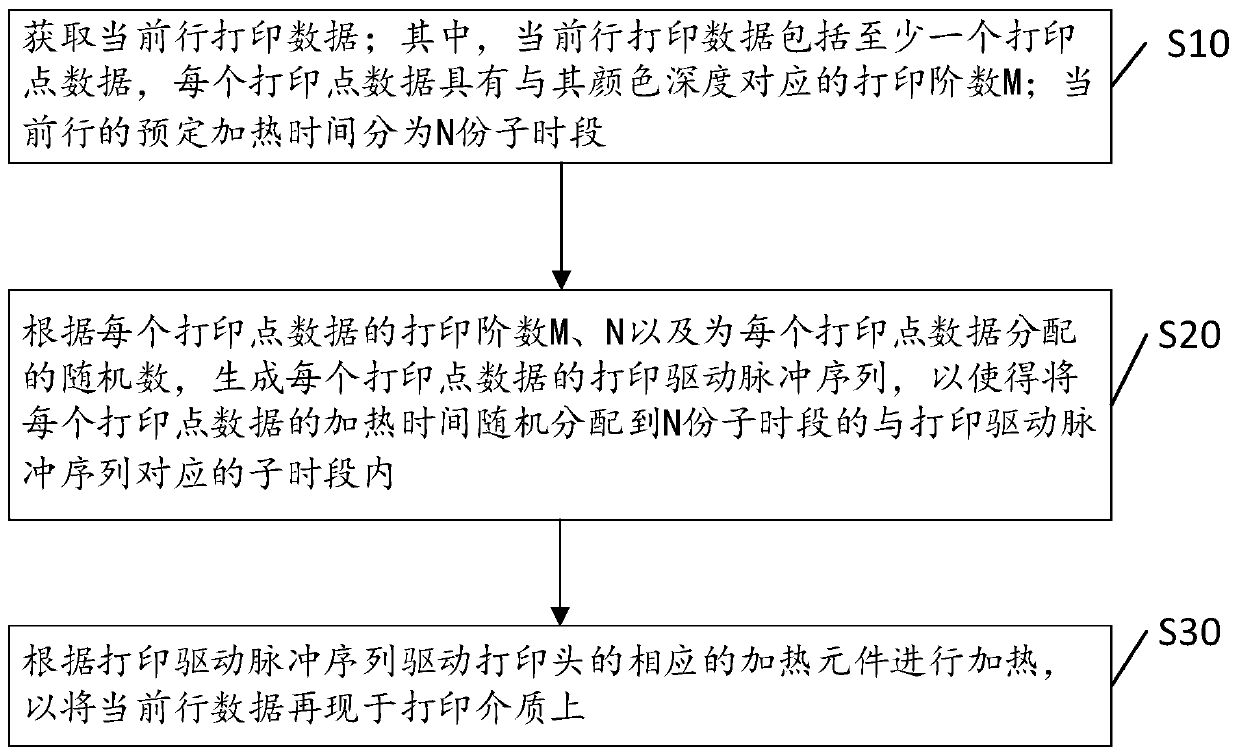

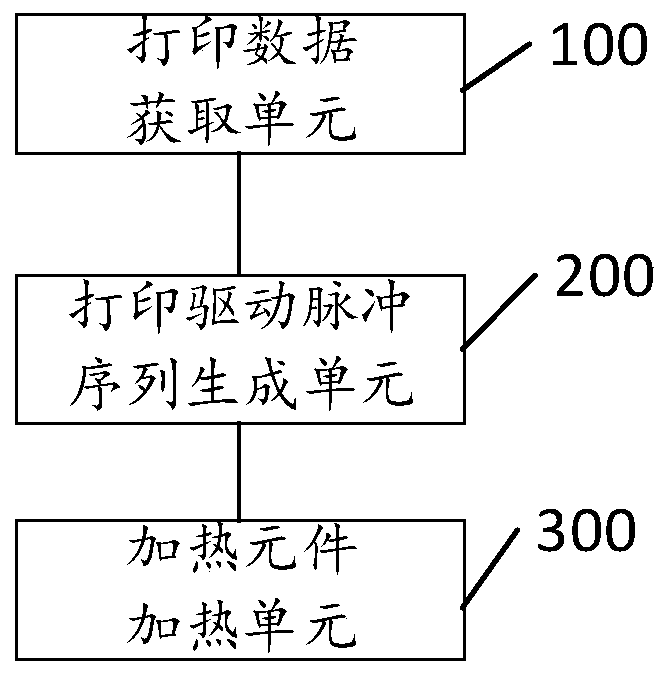

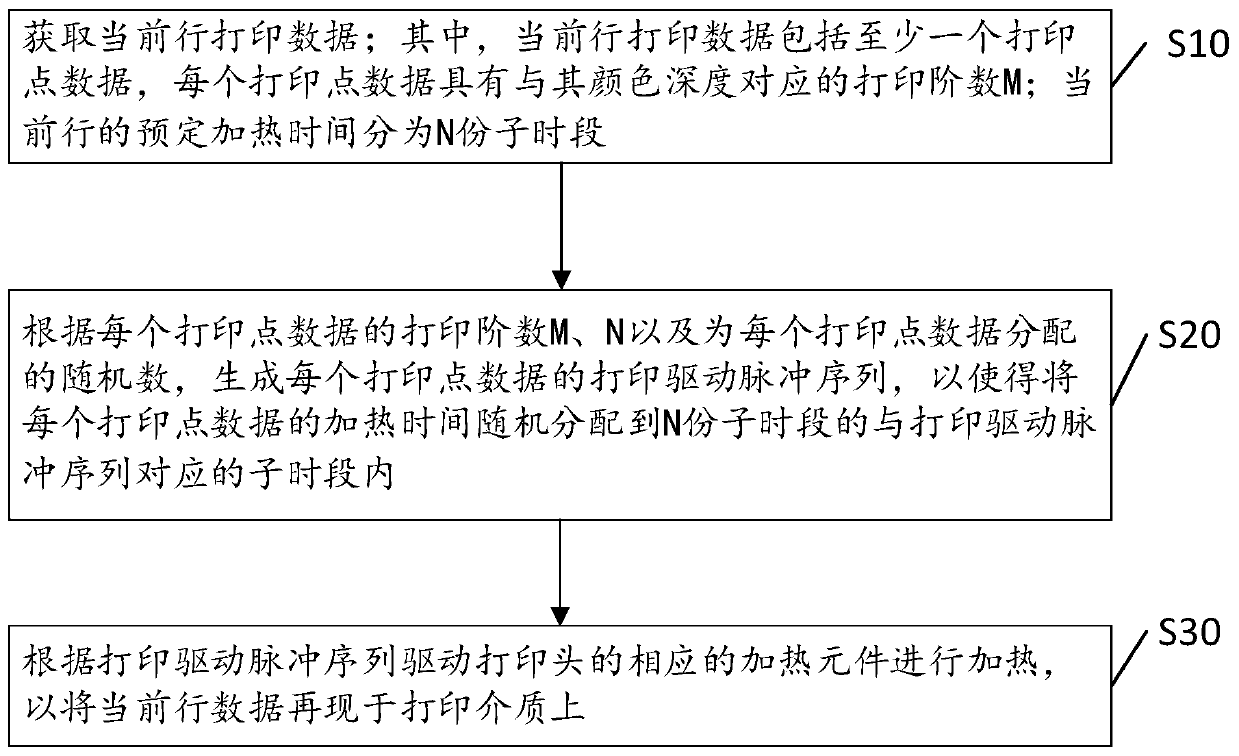

[0060] see figure 1 , the first embodiment of the present invention provides a printing method, which can be executed by a printer, and at least includes the following steps:

[0061] S10, acquire the current line of print data; wherein, the current line of print data includes at least one print point data, each print point data has a printing order M corresponding to its color depth; wherein, the scheduled print time of the current line is divided into N sub-periods .

[0062] In this embodiment, the printer can be a thermal printer, especially a photo printer, which can receive the print data of the image to be printed sent by the user terminal, and print according to the print data.

[0063] In this embodiment, the print data generally includes multiple lines of print data, and each line includes multiple print dot data, and printing needs to be performed line by line during printing, so as to reproduce each print dot data on the printing medium. Further, for photo printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com