Cover plate containing kraft paper

A technology of kraft paper and cover plate, which is applied in the manufacture of paper/cardboard layered products, electrical components, and printed circuits. It can solve the problems of high needle breakage rate and residual glue on the hole wall, and achieve excellent antibacterial and flame retardant properties. , Excellent leveling effect, good salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

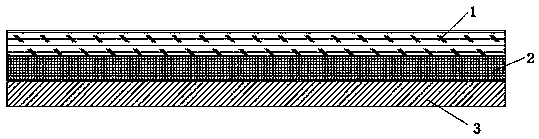

[0024] This embodiment provides a cover plate containing kraft paper. The cover plate includes: a kraft paper layer 1 , a cooling layer 2 and an anti-splash layer 3 from top to bottom.

[0025] The cover plate containing kraft paper provided by the present invention, through the organic cooperation of the kraft paper layer 1 and the cooling layer 2, minimizes the residual glue on the drill bit and the hole wall, protects the drill bit, reduces the wear of the drill bit and reduces the broken needle rate. ; and the anti-drilling layer 3 (that is, one layer in contact with the substrate to be drilled) adopts a polymer resin layer or an aluminum foil, and its hardness and compactness are close to the substrate to be drilled, which can effectively prevent the occurrence of stress on the drill needle. In case of sudden change, the rate of broken needles is reduced, and it also has a certain preventive effect on the burrs on the orifice.

[0026] Further, in the present invention, t...

Embodiment 2

[0033] This embodiment provides a cover plate containing kraft paper. The cover plate includes: a kraft paper layer 1 , a cooling layer 2 and an anti-splash layer 3 from top to bottom.

[0034] The cover plate containing kraft paper provided by the present invention, through the organic cooperation of the kraft paper layer 1 and the cooling layer 2, minimizes the residual glue on the drill bit and the hole wall, protects the drill bit, reduces the wear of the drill bit and reduces the broken needle rate. ; and the anti-drilling layer 3 (that is, one layer in contact with the substrate to be drilled) adopts a polymer resin layer or an aluminum foil, and its hardness and compactness are close to the substrate to be drilled, which can effectively prevent the occurrence of stress on the drill needle. In case of sudden change, the rate of broken needles is reduced, and it also has a certain preventive effect on the burrs on the orifice.

[0035] Further, in the present invention, t...

Embodiment 3

[0041] This embodiment provides a cover plate containing kraft paper. The cover plate includes: a kraft paper layer 1 , a cooling layer 2 and an anti-splash layer 3 from top to bottom.

[0042] The cover plate containing kraft paper provided by the present invention, through the organic cooperation of the kraft paper layer 1 and the cooling layer 2, minimizes the residual glue on the drill bit and the hole wall, protects the drill bit, reduces the wear of the drill bit and reduces the broken needle rate. ; and the anti-drilling layer 3 (that is, one layer in contact with the substrate to be drilled) adopts a polymer resin layer or an aluminum foil, and its hardness and compactness are close to the substrate to be drilled, which can effectively prevent the occurrence of stress on the drill needle. In case of sudden change, the rate of broken needles is reduced, and it also has a certain preventive effect on the burrs on the orifice.

[0043] Further, in the present invention, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com