Manufacturing process of composite paint-free thin-coating wood veneer

A production process and veneer technology, which is applied in the field of production technology of composite paint-free thin-coated veneer, can solve the problems such as the inability to reflect the three-dimensional texture of natural veneer, the inability to improve the production efficiency, the cumbersome production process, etc. The effect of improving market competitiveness and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

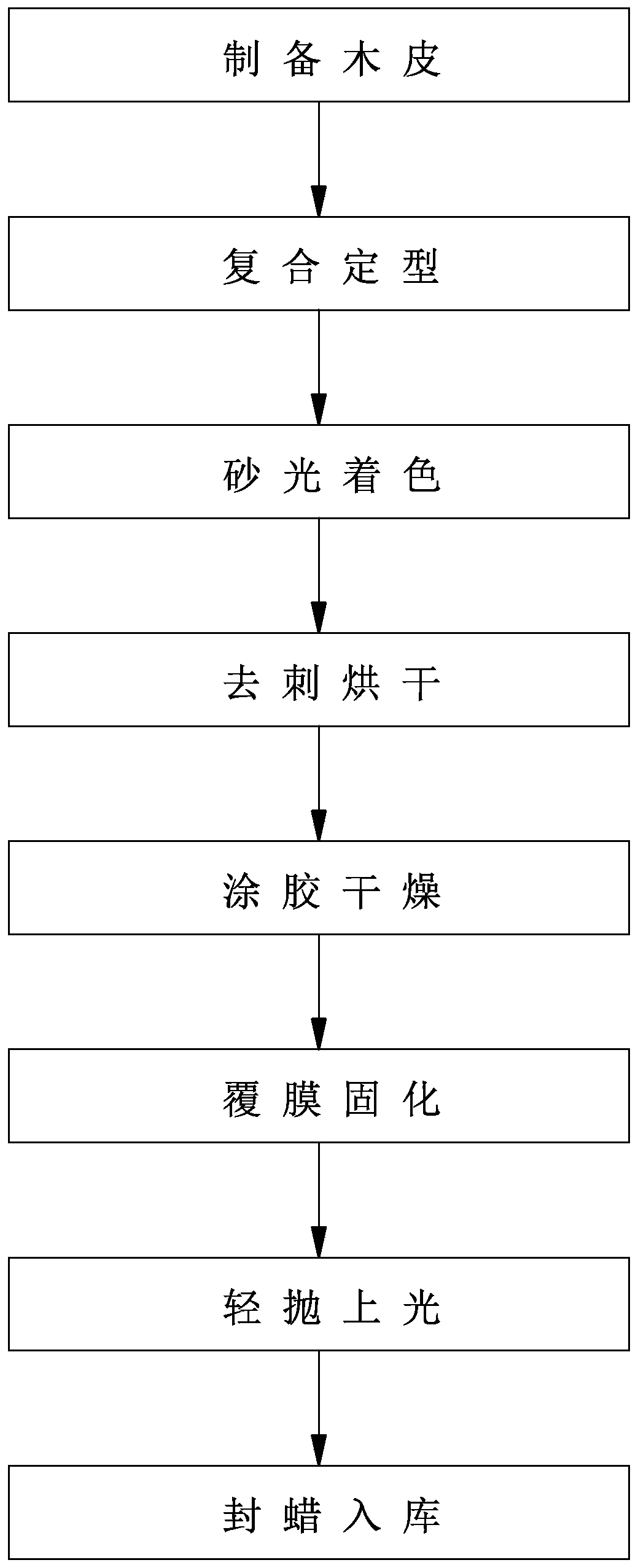

[0029] The manufacturing process of the composite paint-free thin-coated veneer comprises the following steps:

[0030] Step 1. Preparation of veneer: use natural trees as raw materials, select and cut logs to obtain a predetermined length, then select uncracked logs, and slice them according to the log texture, and then prepare a veneer with a length and width of 500x 150mm and a thickness of 4mm ;

[0031] Step 2. Composite shaping: apply environmentally friendly glue on the surface of the substrate that is composited with the veneer, and then adhere the veneer to the substrate to form a composite assembly, and then perform hot pressing on the composite assembly. The temperature is 80°C, the hot pressing pressure is 10kgf / c㎡, and the hot pressing time is 280s, and then the veneer is hot-pressed and shaped on the substrate to form a composite blank;

[0032] Step 3, sanding and coloring: sanding the veneer on the composite blank with a sander to make the surface of the venee...

Embodiment 2

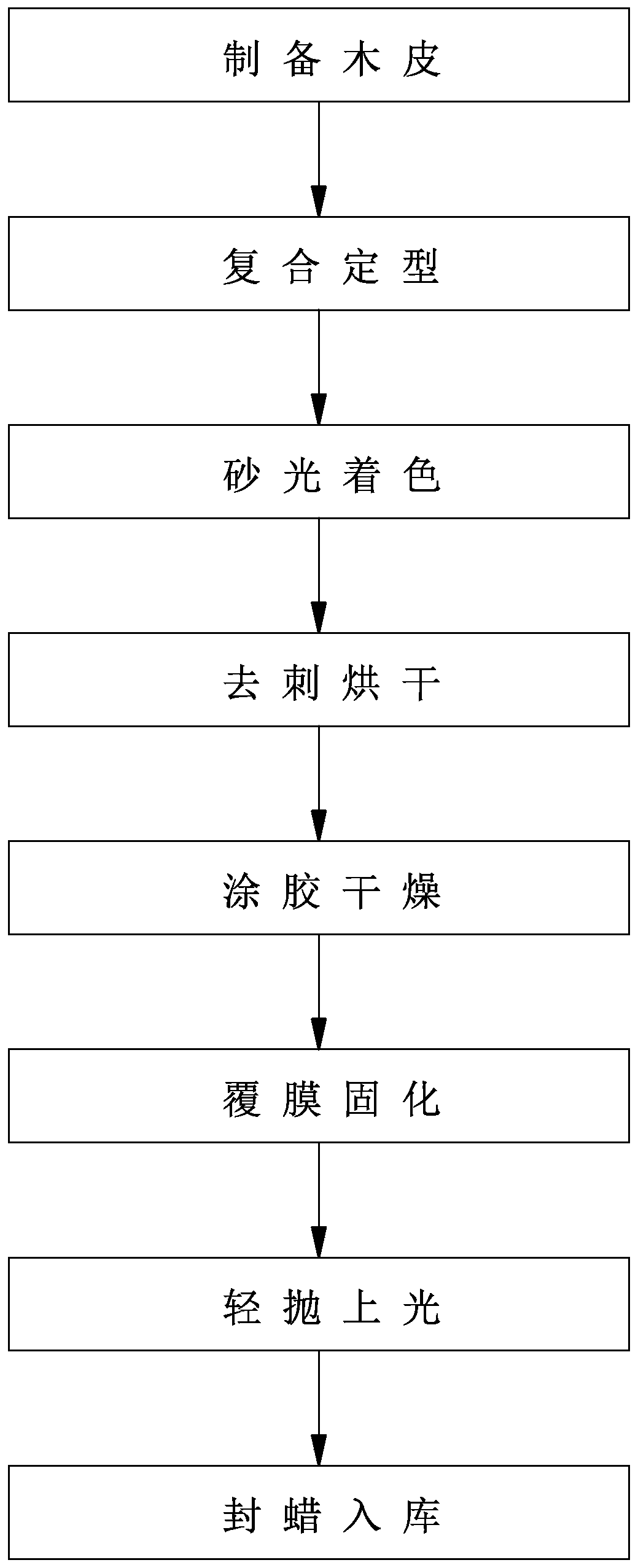

[0039] The manufacturing process of the composite paint-free thin-coated veneer comprises the following steps:

[0040] Step 1. Preparation of veneer: use natural trees as raw materials, select and cut logs to obtain a predetermined length, then select uncracked logs, and slice them according to the log texture, and then prepare a veneer with a length and width of 500x 150mm and a thickness of 4mm ;

[0041] Step 2. Composite shaping: apply environmentally friendly glue on the surface of the substrate that is composited with the veneer, and then adhere the veneer to the substrate to form a composite assembly, and then perform hot pressing on the composite assembly. The temperature is 90°C, the hot pressing pressure is 8.5kgf / c㎡, the hot pressing time is 350s, and then the veneer is hot pressed on the substrate to form a composite blank;

[0042] Step 3, sanding and coloring: sanding the veneer on the composite blank with a sander to make the surface of the veneer smooth, then...

Embodiment 3

[0049] The manufacturing process of the composite paint-free thin-coated veneer comprises the following steps:

[0050] Step 1. Preparation of veneer: use natural trees as raw materials, select and cut logs to obtain a predetermined length, then select uncracked logs, and slice them according to the log texture, and then prepare a veneer with a length and width of 500x 150mm and a thickness of 4mm ;

[0051] Step 2. Composite shaping: apply environmentally friendly glue on the surface of the substrate that is composited with the veneer, and then adhere the veneer to the substrate to form a composite assembly, and then perform hot pressing on the composite assembly. The temperature is 100°C, the hot pressing pressure is 9kgf / c㎡, and the hot pressing time is 375s, and then the veneer is hot pressed on the substrate to form a composite blank;

[0052] Step 3, sanding and coloring: sanding the veneer on the composite blank with a sander to make the surface of the veneer smooth, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com