Variable cylinder hole reaming and honing floating tool

A variable cylinder, reaming and honing technology, applied in the field of variable cylinder reaming and honing floating tooling, can solve the problem of no self-centering function, and achieve the effects of simple structure, providing machining accuracy and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

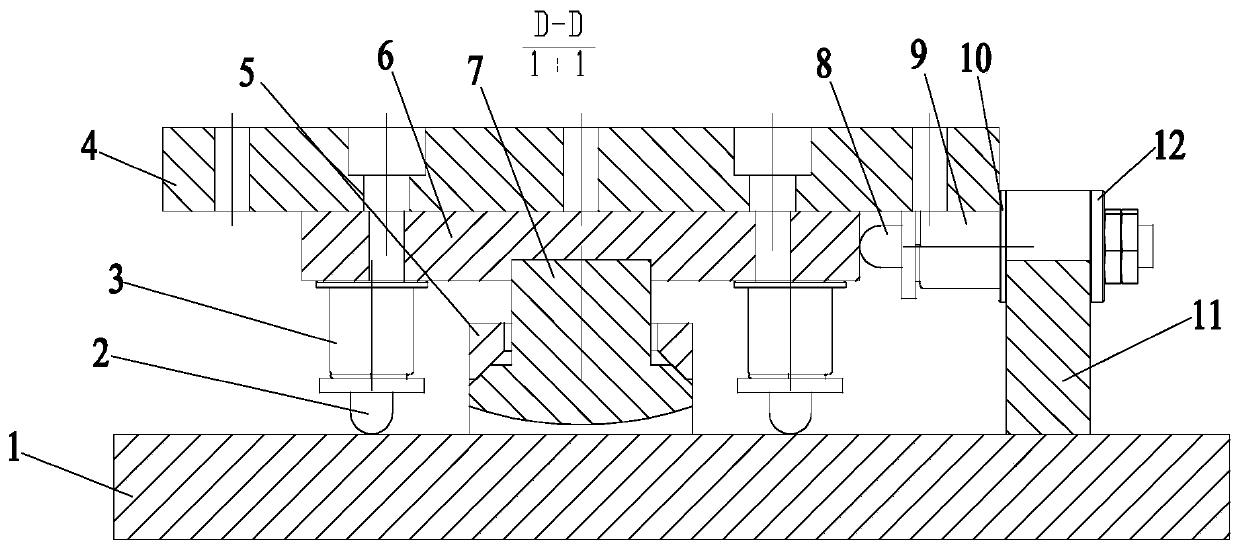

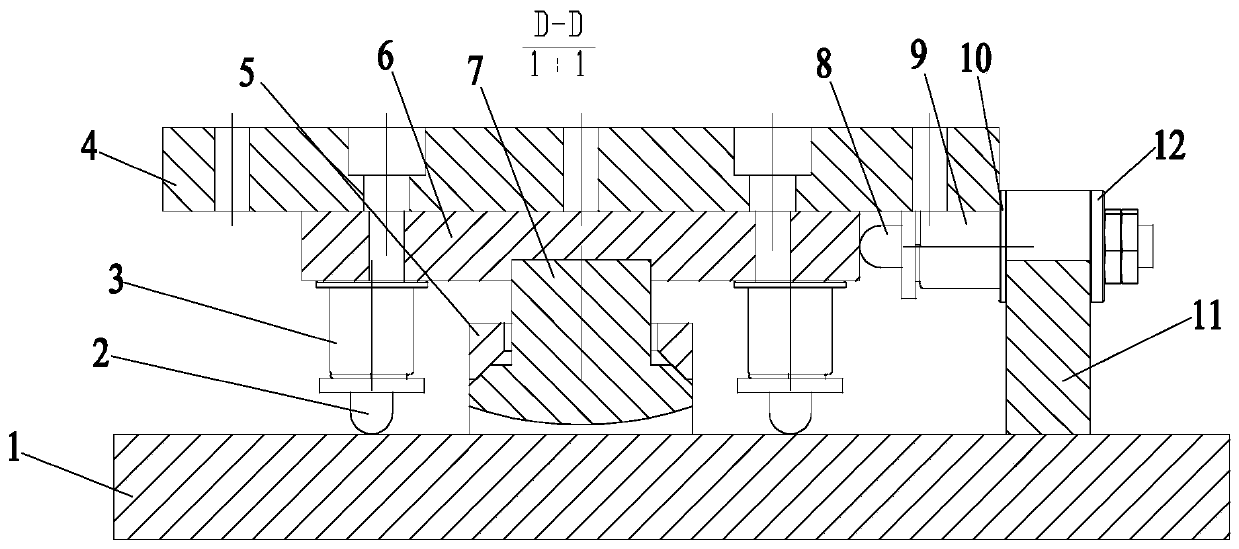

[0012] figure 1 , 2 Including installation plate 1, support pin 2, spring 3, workpiece fixture installation base plate 4, centering plate 5, connecting plate 6, ball head floating shaft 7, support pin 8, spring 9, spring seat 10, support pin installation plate 11. Gasket 12, etc.

[0013] Such as figure 1 , 2 As shown, the present invention is a variable cylinder reaming hole floating tool, including a mounting plate 1, the upper surface of the mounting plate 1 is vertically provided with a support pin mounting plate 11, and the support pin mounting plate 11 is provided with an elastically expandable first Support pin 8, the centering plate 5 is also fixed on the upper surface of the mounting plate 1; the workpiece fixture installation base plate 4 is arranged in parallel above the mounting plate 1, the bottom surface of the workpiece fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com