High-speed rail wheel electromagnetic tomography flaw detection method and device

A technology of electromagnetic tomography and high-speed rail, applied in the direction of material magnetic variables, etc., can solve the problems of high cost of radiographic flaw detection, high requirements for staff, and radiation, and achieve the effects of rapid on-site detection, easy portability, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

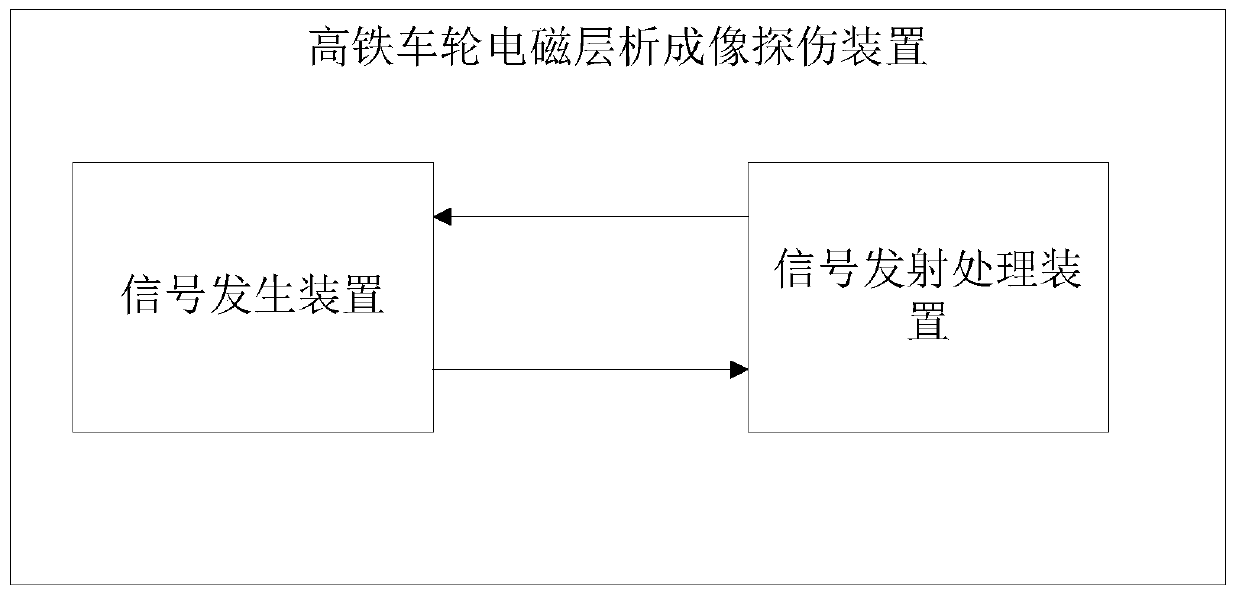

[0043] figure 1 It is the schematic diagram of the high-speed rail wheel electromagnetic tomography flaw detection device of the present embodiment, referring to figure 1 , the device includes: a signal generating device and a signal transmission processing device.

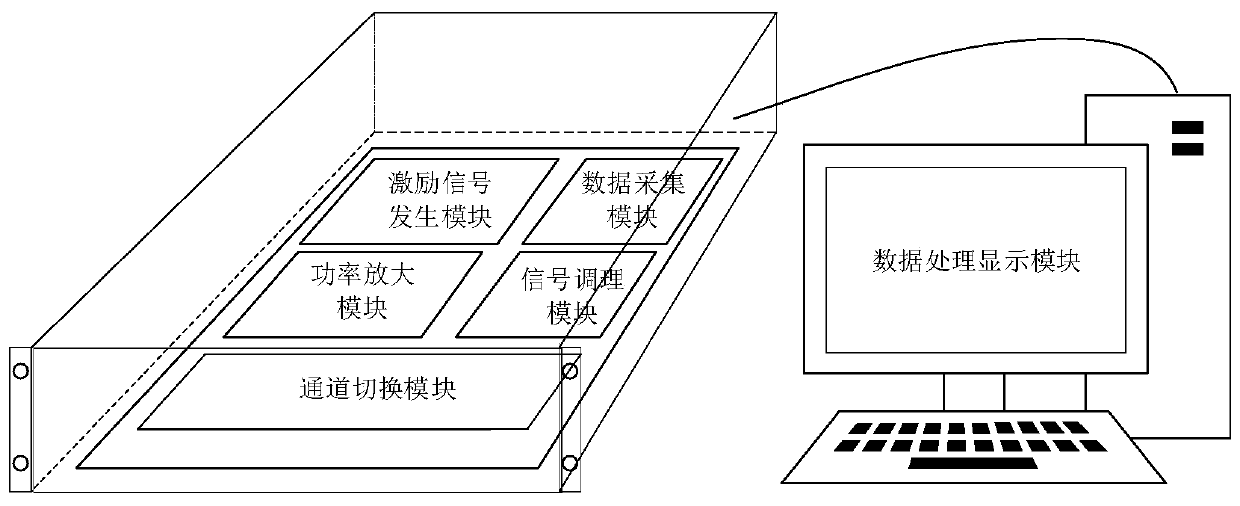

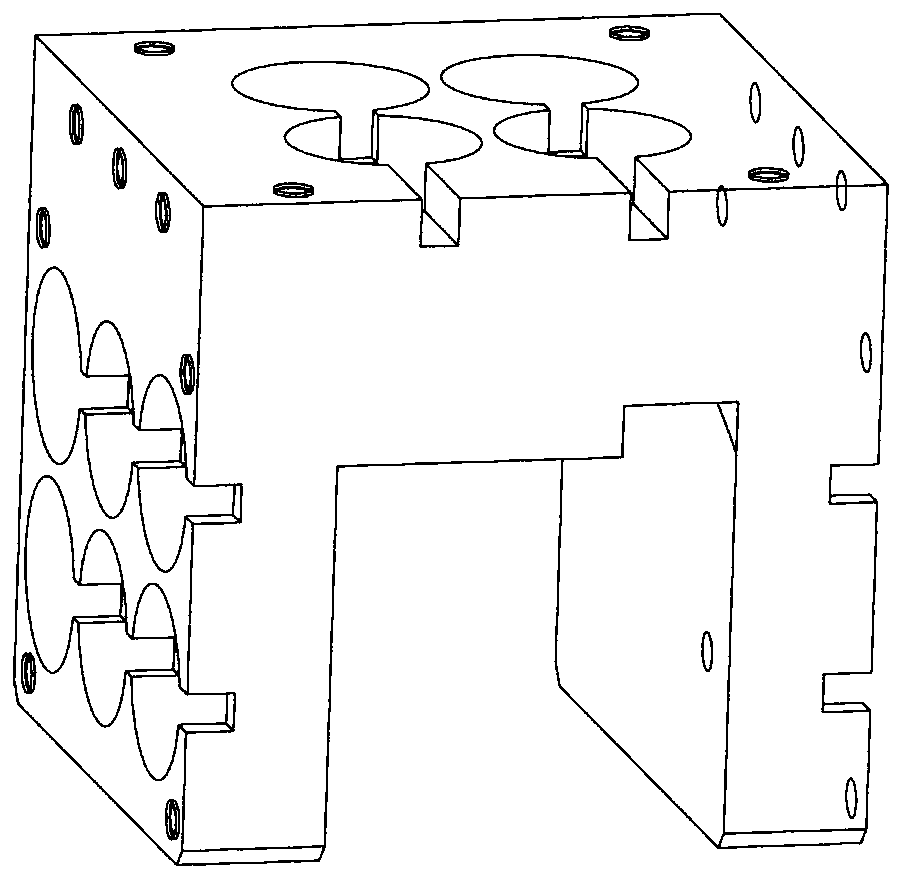

[0044]The signal generating device includes a U-shaped electromagnetic tomography sensor bracket and an electromagnetic coil, and the electromagnetic coil is evenly installed in the U-shaped electromagnetic tomography sensor bracket, and is used to transmit the signal according to the signal transmission processing device, Collect the induced voltage signal of the high-speed rail wheel. When in use, the U-shaped electromagnetic tomography sensor bracket is fixedly installed on the flaw detection platform to detect the rim, tread and rim of the high-speed rail wheel. image 3 It is a schematic diagram of U-shaped electromagnetic tomography sensor bracket, refer to image 3 , there are 2n grooves on the U-shaped ...

Embodiment 2

[0060] Electromagnetic tomography is a new type of electrical tomography based on the principle of electromagnetic induction. By applying multi-frequency excitation signals to the excitation coil, an alternating excitation main magnetic field will be generated in the measured object field. It will generate multi-frequency eddy currents in the measured object, and the eddy currents will induce secondary magnetic fields. The secondary magnetic field is coupled with the main magnetic field to generate a distorted magnetic field. The distorted magnetic field acts on the detection coil, and a voltage signal is induced on the detection coil. Each coil is excited in turn, and the other coils are detected in turn, so that the projection data in all directions can be obtained. Finally, a suitable image reconstruction algorithm is used to reconstruct the defect distribution of the cross-section of the high-speed rail wheel.

[0061] Figure 5 This embodiment provides a flow chart of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com