Fuel oil filter applied to gas turbine

A technology of fuel oil filter and gas turbine, which is applied to the fuel valve of turbine/propulsion device, engine components, turbine/propulsion fuel delivery system, etc. It can solve the problems of large volume, poor shock and vibration resistance, etc., to ensure sealing performance, The effect of high reliability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

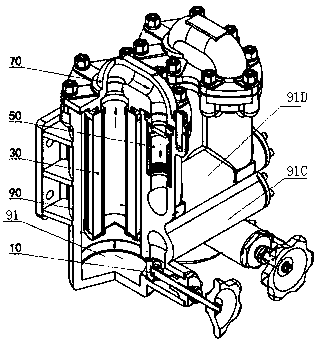

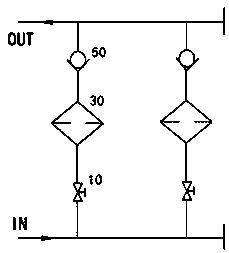

[0022] A fuel filter applied to a gas turbine, comprising a filter housing 90, such as Figure 1-Figure 7 As shown, the filter housing 90 is provided with an inlet main pipe 91C and an outlet main pipe 91D, and the inlet main pipe 91C is respectively connected to one end of two shut-off valves 10 installed in the filter housing 90, and the other end of the shut-off valve 10 is Connected with the bottom end of the filter cartridge 91, the filter cartridge 91 is provided with a filter element 30, the upper end of the filter cartridge 91 is connected to one end of the check valve 50 through the filter cover 70, and the other end of the check valve 50 is connected to the outlet main pipe 91D. There are two filter cartridges 91 , filter elements 30 , filter covers 70 and check valves 50 , and they are all symmetrically arranged in the filter housing 90 .

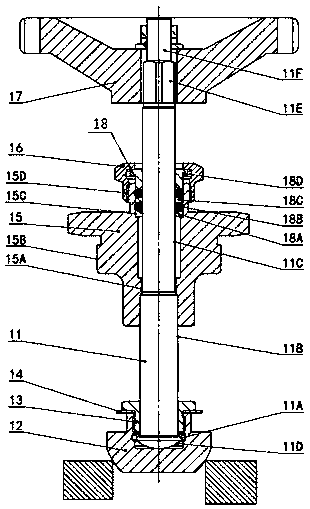

[0023] The stop valve 10 includes a valve stem 11, a valve 12, a nut 13, a stop washer 14, a screw plug 15, a compression nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com