A column-column-beam assembly integrated variable beam height node and its construction method

A prefabricated, node technology, applied in the direction of architecture, building structure, etc., can solve problems such as singleness, and achieve the effect of reducing weak links, increasing safety, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

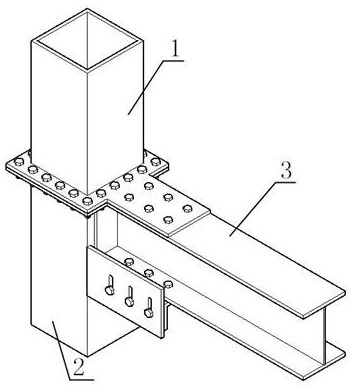

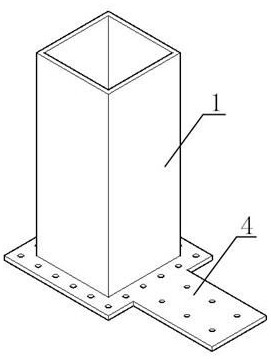

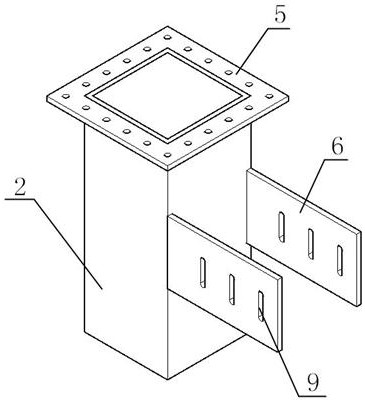

[0034] refer to Figure 1-6 , in an embodiment of the present invention, a column-column-beam assembly type integrated variable beam height node, the node includes a steel pipe column section 1 above the node area, a steel pipe column section 2 below the node area, and an H-shaped steel beam section 3 in the node area and connectors, the connectors include T-shaped flange plate 4, lower column square flange plate 5, ear plate 6, end plate 7 and independently arranged connector 8; T-shaped flange plate 4 is welded to the upper steel pipe column section 1 , the square flange plate 5 and ear plate 6 are welded to the lower steel pipe column section 2, and the end plate 7 is welded to the H-shaped beam section 3; cutting to avoid collision between the square flange plate 5 and the H-shaped steel beam during installation.

specific Embodiment approach 2

[0036] The T-shaped flange plate 4 of the upper column and the square flange plate 5 of the lower column are connected by high-strength bolts, and the axial force, shear force and bending moment of the upper column are transmitted to the lower column section to realize the connection of the upper and lower steel pipe columns. The H-shaped beam 2 The upper flange is connected to the T-shaped flange plate 4 of the upper column through high-strength bolts, and the lower flange is connected to the ear plate 6 on the column side through the connecting piece 8 and high-strength bolts, so as to transmit the bending moment and shear force of the beam section to the ear plate, realizing the H-shaped The steel beam is connected to the square steel pipe column, and then the integrated connection of column-column-beam assembly is realized at the same time.

specific Embodiment approach 3

[0038] The ear plates 6 are symmetrically welded on both sides of the lower steel pipe column 2, aligned with the outer edge of the column, and the ribs are welded inside the column, and connected with the connector 8 through high-strength bolts. The connecting piece 8 is groove-shaped, and its width is equal to the difference between the width of the column and the thickness of the ear plate. The connecting piece 8 is arranged between two ear plates 6, and forms a reliable connection with the ear plate 6 on the column side and the lower flange of the steel beam through high-strength bolts; The lug plate 6 has an oblong hole 9, and the bolt connected to the connector 8 can slide freely up and down in the oblong hole. During implementation, the installation elevation of the connector 8 can be freely adjusted according to the height of the H-shaped beam 2, so that the same node can be adapted to different heights. The connection of H-shaped beams increases the versatility of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com