Pipeline for nitrogen crystal pulling and nitrogen-doping single crystal pulling process

A technology of nitrogen tube and nitrogen, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems that the furnace gas cannot be switched, the chemical properties are inactive, and only argon can be used, so as to reduce the crystal pull. cost, ease of installation, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

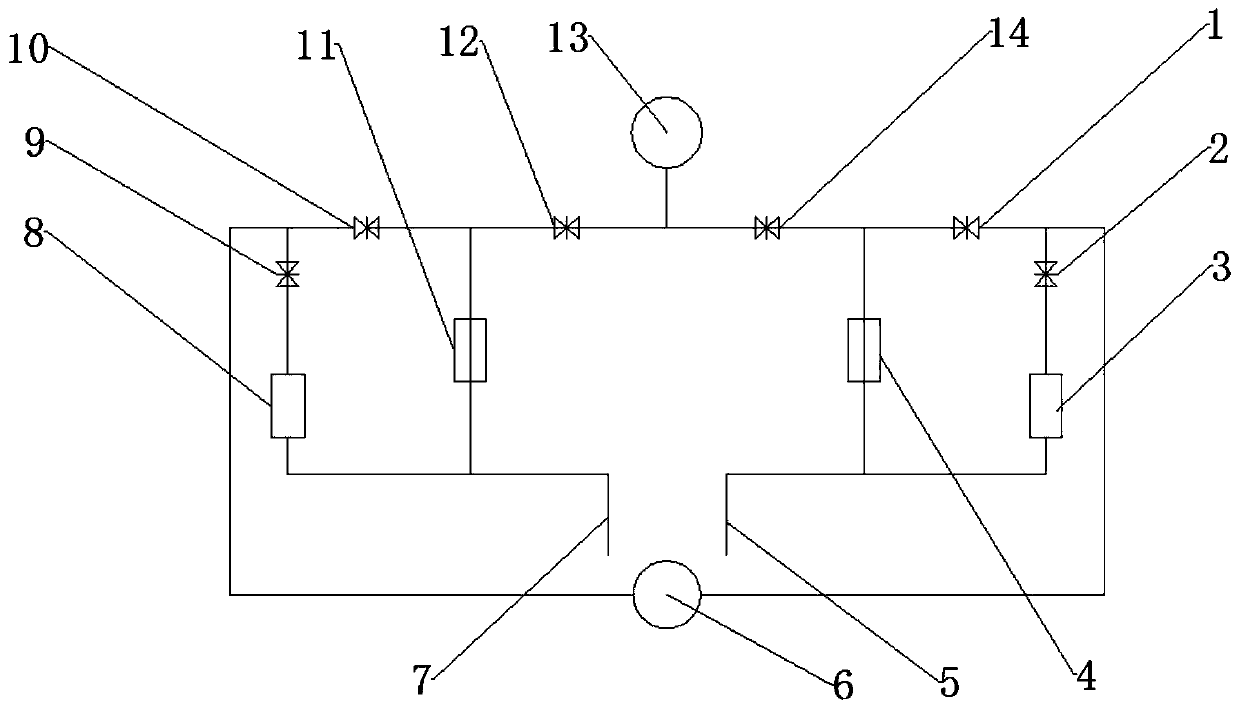

[0029] The present embodiment will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] figure 1 The structure of an embodiment of the present invention is shown, and the specific pipeline connection relationship of this embodiment is shown. This embodiment relates to a pipeline for nitrogen gas pulling crystals and the use of the pipeline for nitrogen gas pulling crystals for nitrogen doping single The crystal pulling process is suitable for use in the Czochralski single crystal process. When the Czochralski single crystal is pulled, the nitrogen gas distribution plate and the argon gas distribution plate are connected in pipelines, and are respectively connected to the main chamber and the auxiliary chamber of the single crystal furnace. Nitrogen and argon are input to the single crystal furnace, and the feeding time and flow rate of nitrogen and argon are controlled to realize the pull-down in the atmosphere of nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com