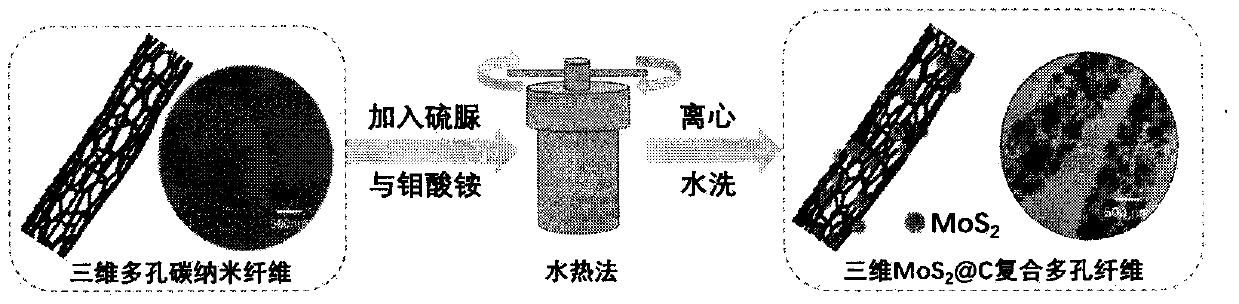

Preparation method of three-dimensional MoS2@C composite porous fiber for lithium ion capacitor negative electrode material

A technology of porous fibers and negative electrode materials, which is applied in the field of preparation of three-dimensional MoS2@C composite porous fibers for lithium ion capacitor negative electrode materials, which can solve problems such as difficult loading, carbon nanofibers with less pores, and difficulty in large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention firstly prepares a three-dimensional porous carbon nanofiber matrix material based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery cathode material and its preparation method (CN105161722A).

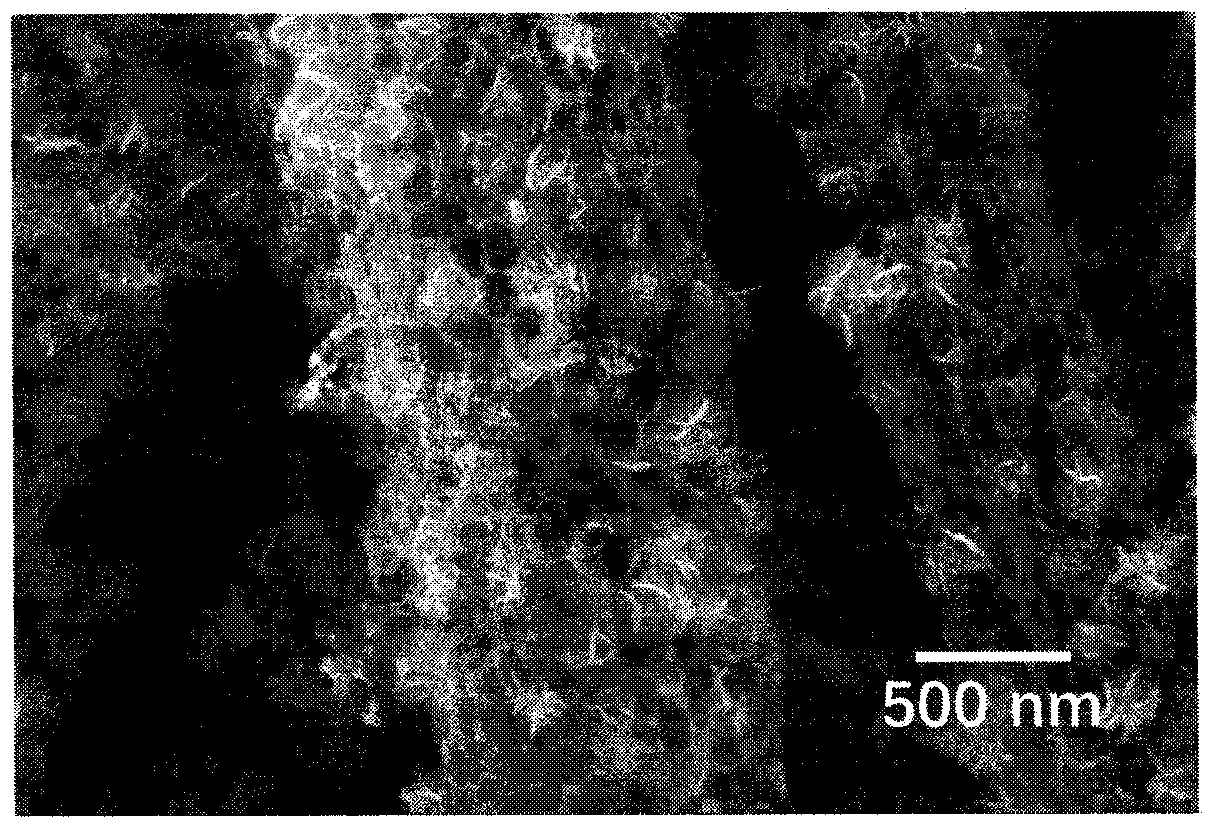

[0022] The three-dimensional porous carbon nanofiber matrix material is uniformly dispersed in distilled water by means of stirring and ultrasound, and ammonium molybdate is added with ammonium molybdate: three-dimensional porous carbon nanofiber matrix material molar ratio of 4: 1, and ammonium molybdate: The molar ratio of thiourea is 1:28. Add thiourea to prepare the reaction solution, and transfer it to a hydrothermal reaction kettle. The hydrothermal reaction temperature is controlled at 200°C, and the hydrothermal reaction time is 6h. , to remove excess impurities on the surface, and after vacuum drying, a three-dimensional MoS 2 @C composite porous fiber with a specific surf...

Embodiment 2

[0024] The present invention firstly prepares a three-dimensional porous carbon nanofiber matrix material based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery cathode material and its preparation method (CN105161722A).

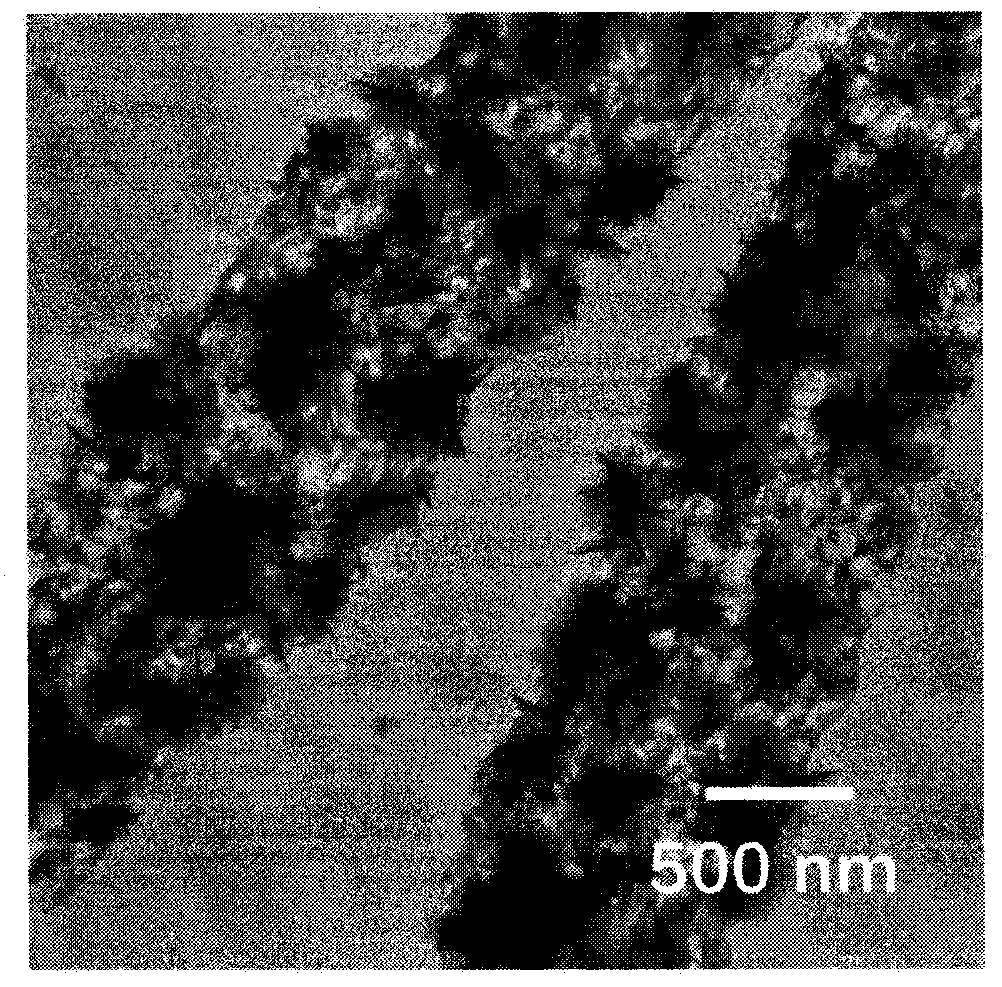

[0025] By means of stirring and ultrasound, etc., the three-dimensional porous carbon nanofiber matrix material is uniformly dispersed in distilled water, ammonium molybdate is added with ammonium molybdate: the three-dimensional porous carbon nanofiber matrix material molar ratio is 2: 1, and ammonium molybdate: The molar ratio of thiourea is 1:28. Add thiourea to prepare the reaction solution, and transfer it to a hydrothermal reaction kettle. The hydrothermal reaction temperature is controlled at 180°C, and the hydrothermal reaction time is 4h. , to remove excess impurities on the surface, and after vacuum drying, a three-dimensional MoS 2 @C composite porous fiber with a specif...

Embodiment 3

[0027] The present invention firstly prepares a three-dimensional porous carbon nanofiber matrix material based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery cathode material and its preparation method (CN105161722A).

[0028] By means of stirring and ultrasound, etc., the three-dimensional porous carbon nanofiber matrix material is uniformly dispersed in distilled water, ammonium molybdate is added with ammonium molybdate: three-dimensional porous carbon nanofiber matrix material molar ratio is 5: 1, and ammonium molybdate: The molar ratio of thiourea is 1:28. Add thiourea to prepare the reaction liquid, and transfer it to a hydrothermal reaction kettle. The hydrothermal reaction temperature is controlled at 240°C, and the hydrothermal reaction time is 12h. , to remove excess impurities on the surface, and after vacuum drying, a three-dimensional MoS 2 @C composite porous fiber with a specific su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com