A high temperature resistant flexible flat cable and its processing technology

A flat cable and processing technology, applied in the direction of flat/ribbon cables, cables, insulated cables, etc., to achieve the effect of improving signal transmission capacity, overcoming lamination and non-welding, and improving extreme temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described in non-limiting detail below in conjunction with the preferred embodiments and the accompanying drawings.

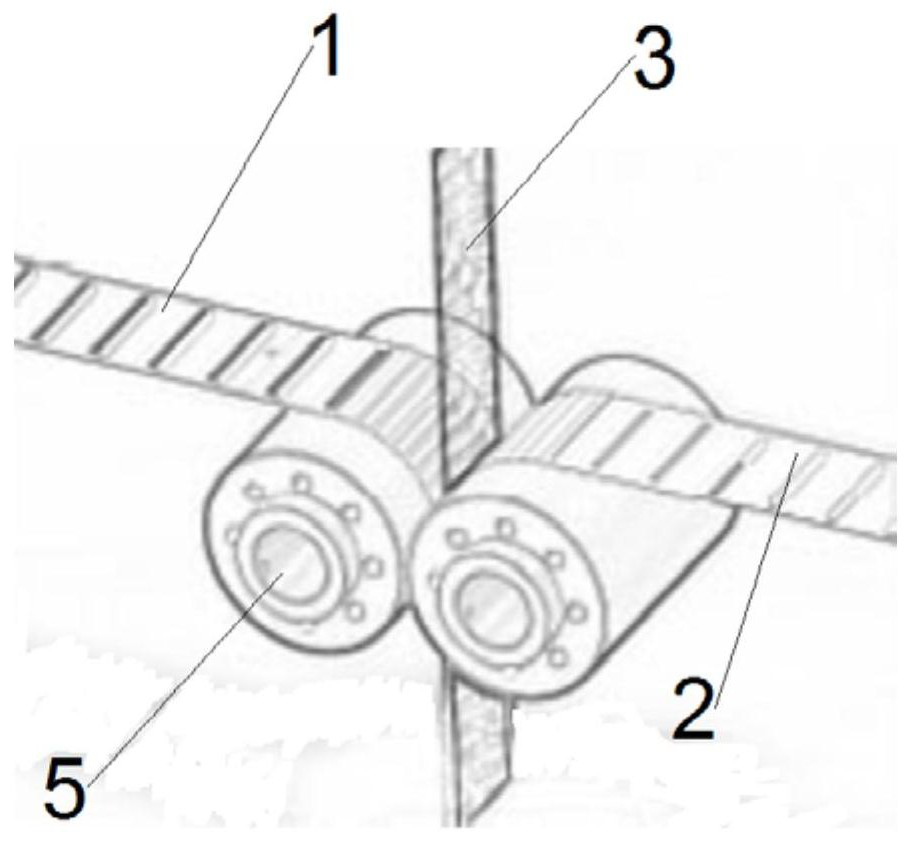

[0027] like Figure 1 to Figure 5 As shown, this embodiment provides a high temperature resistant flexible flat cable and a processing technology. The flexible flat cable includes an upper PI adhesive film 1, a lower PI adhesive film 2, and a PI adhesive film 1, 2 attached between the upper and lower PI adhesive films. the flat conductor 3.

[0028] The flexible flat cable processing process specifically includes the following steps:

[0029] S1. Conductor calendering; press the circular section copper conductor into a flat copper conductor 3 of a specified specification by a calendering machine. The calender is known in the art and will not be repeated in the present invention.

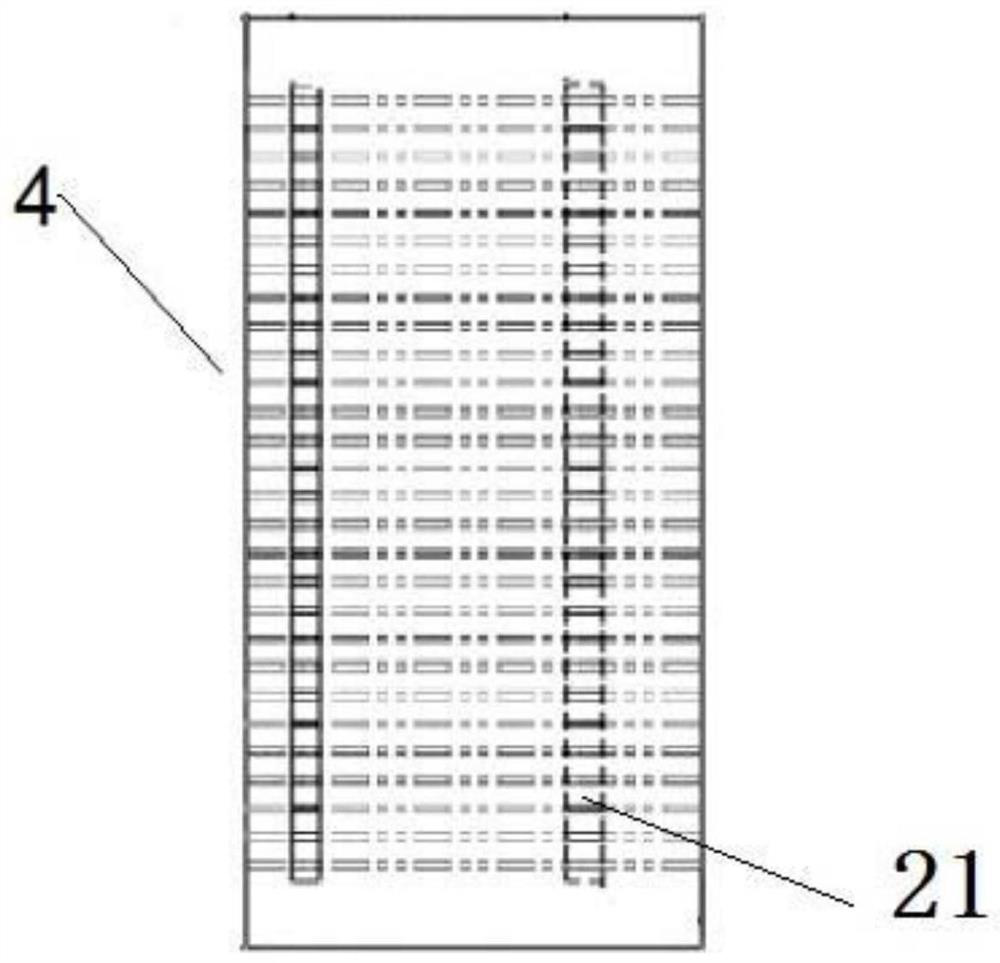

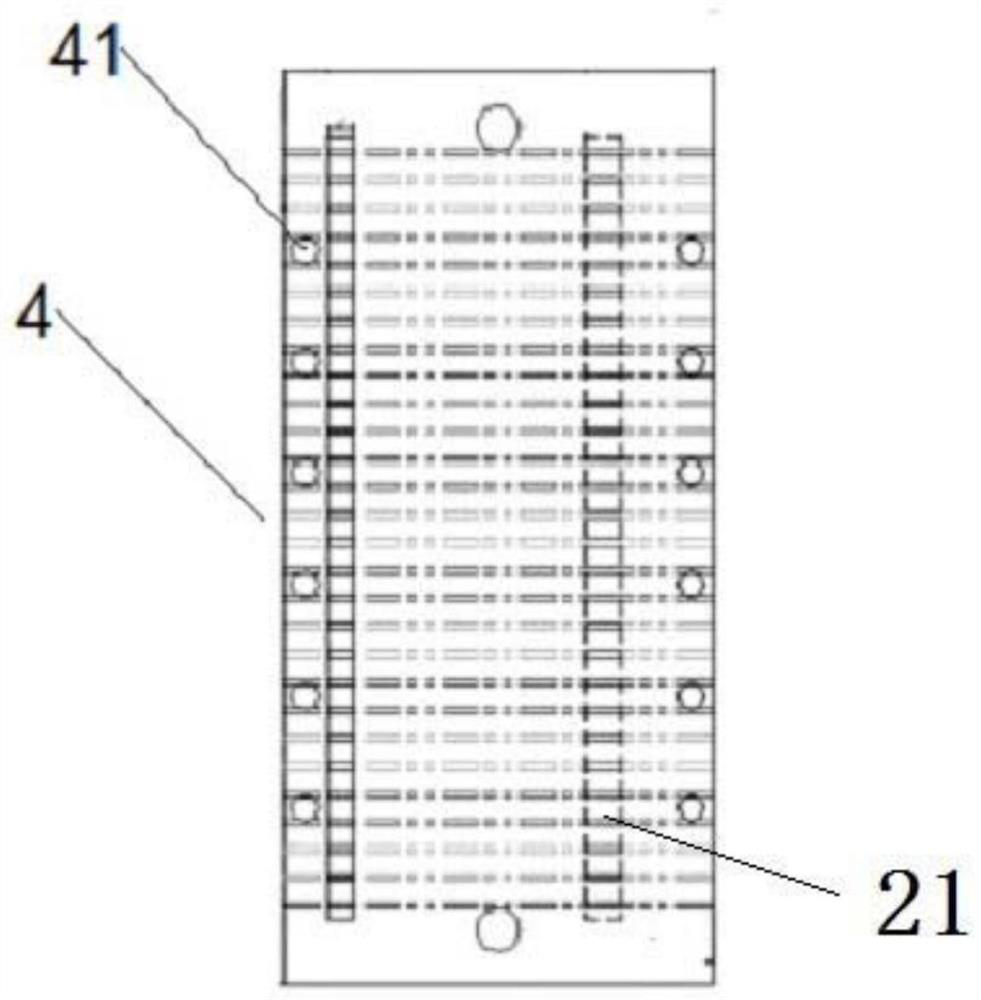

[0030] S2. Punching the film; punching the PI film by the FFC molding machine, and punching out the square hole 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com