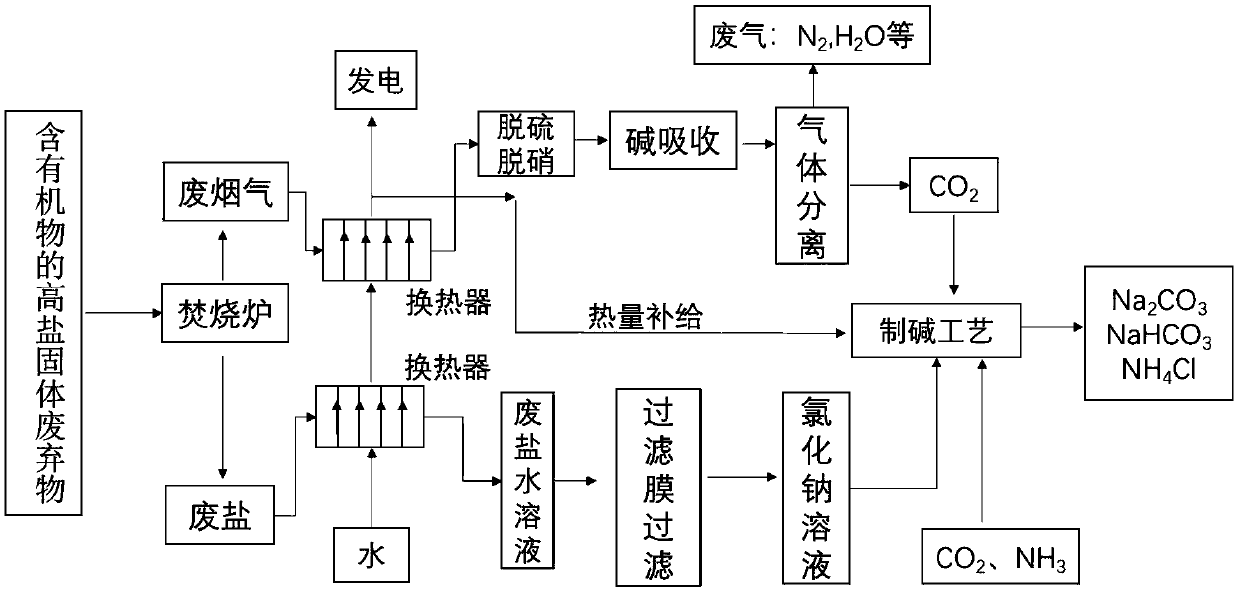

Treatment method of high-salt solid waste containing organic matters

A solid waste and treatment method technology, which is applied in the field of high-salt solid waste treatment and can solve problems such as unsatisfactory membrane performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

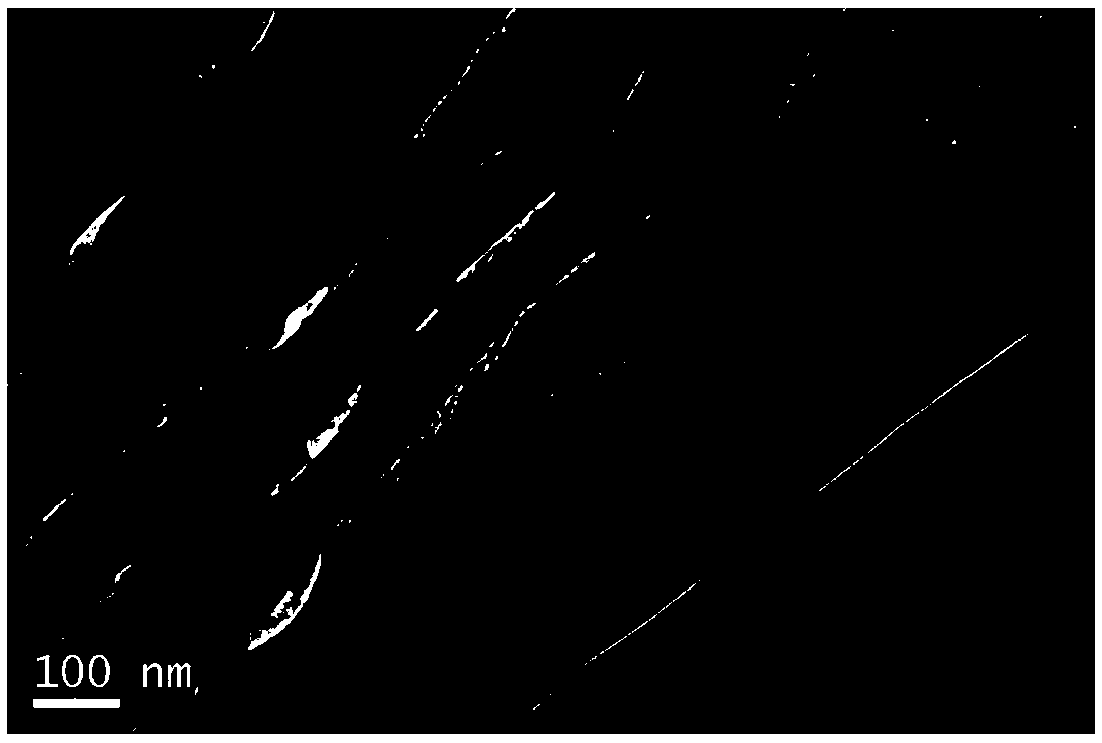

[0111] Dissolve 5 parts of block polyether amide copolymer (Pebax2533 for the grade) in 40 parts of isopropanol, heat and stir, control the temperature at 80°C, and heat for 5 hours to form a sol solution. Weigh 5 parts of nanocrystalline SiO2 (particle size range 20-40nm) solid, dissolve it in 10 parts of isopropanol, stir and mix evenly, add it dropwise into the mixed sol, and stir for 30 minutes to obtain a nanocrystalline SiO2 polymer mixed solution. 30 parts of polyacrylonitrile carbon fibers were impregnated with the nanocrystalline SiO2 polymer mixed solution, and pulled out at a rate of 5 cm / min. The modified carbon fibers were dried at 80° C. for 12 hours. Then high temperature treatment at 1300°C for 3h in Ar atmosphere. The TEM picture of the carbon fiber that present embodiment obtains is as figure 1 shown.

Embodiment 2

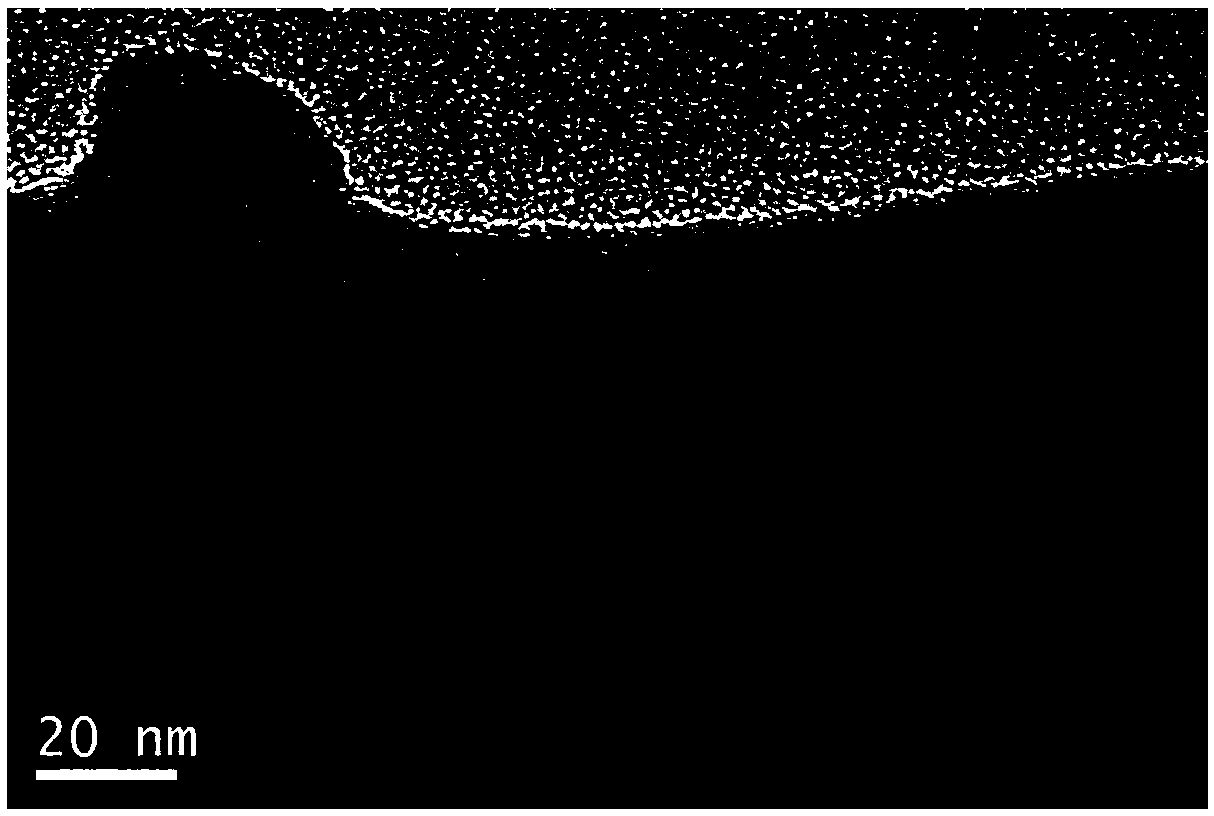

[0113] Dissolve 20 parts of polyetheramide copolymer (Pebax3533 for the grade) in 20 parts of isopropanol, heat and stir, control the temperature at 80°C, and heat for 12 hours to form a sol solution. Weigh nanocrystalline SiO 2 (Particle size range 40-100nm) 20 parts, dissolved in 10 parts of isopropanol, stirred and mixed evenly, added dropwise to the mixed sol, stirred for 30 minutes to obtain nanocrystalline SiO 2 Polymer mixed solution. 10 parts of polyacrylonitrile carbon fibers were impregnated with the nanocrystalline SiO 2 The polymer mixed solution is pulled out afterward, and the extraction speed is 20cm / min. Dry the modified carbon fiber at 80°C for 12h. Then it was treated at 1500°C for 10h in an Ar atmosphere. The TEM picture of the carbon fiber that present embodiment obtains is as figure 2 shown.

Embodiment 3

[0115] Dissolve 5 parts of polyether amide copolymer (Pebax7233 for the grade) in 40 g of tetrahydrofuran, heat and stir, control the temperature at 80°C, and heat for 5 hours to form a sol solution. Weigh nanocrystalline SiO 2 (Particle size range 100-300nm) 5 parts, dissolved in 20 parts of tetrahydrofuran, stirred and mixed evenly, added dropwise into the mixed sol, stirred for 30 minutes, to obtain nanocrystalline SiO 2 Polymer mixed solution. 50 parts of polyacrylonitrile carbon fibers were impregnated with the nanocrystalline SiO 2 The polymer mixed solution is pulled out afterward, and the extraction speed is 5cm / min. Dry the modified carbon fiber at 80°C for 12h. Then high temperature treatment at 1300°C for 10h in Ar atmosphere. The TEM picture of the carbon fiber that present embodiment obtains is as image 3 As shown, the XRD pattern is as Figure 4 shown.

[0116] Table 1 uses different nanocrystalline SiO for carbon fibers 2 Comparison of mechanical proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com