Leveling control loop and control method based on hydraulic control self-locking

A technology of control loop and control method, applied in the direction of servo motor components, fluid pressure actuation system components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

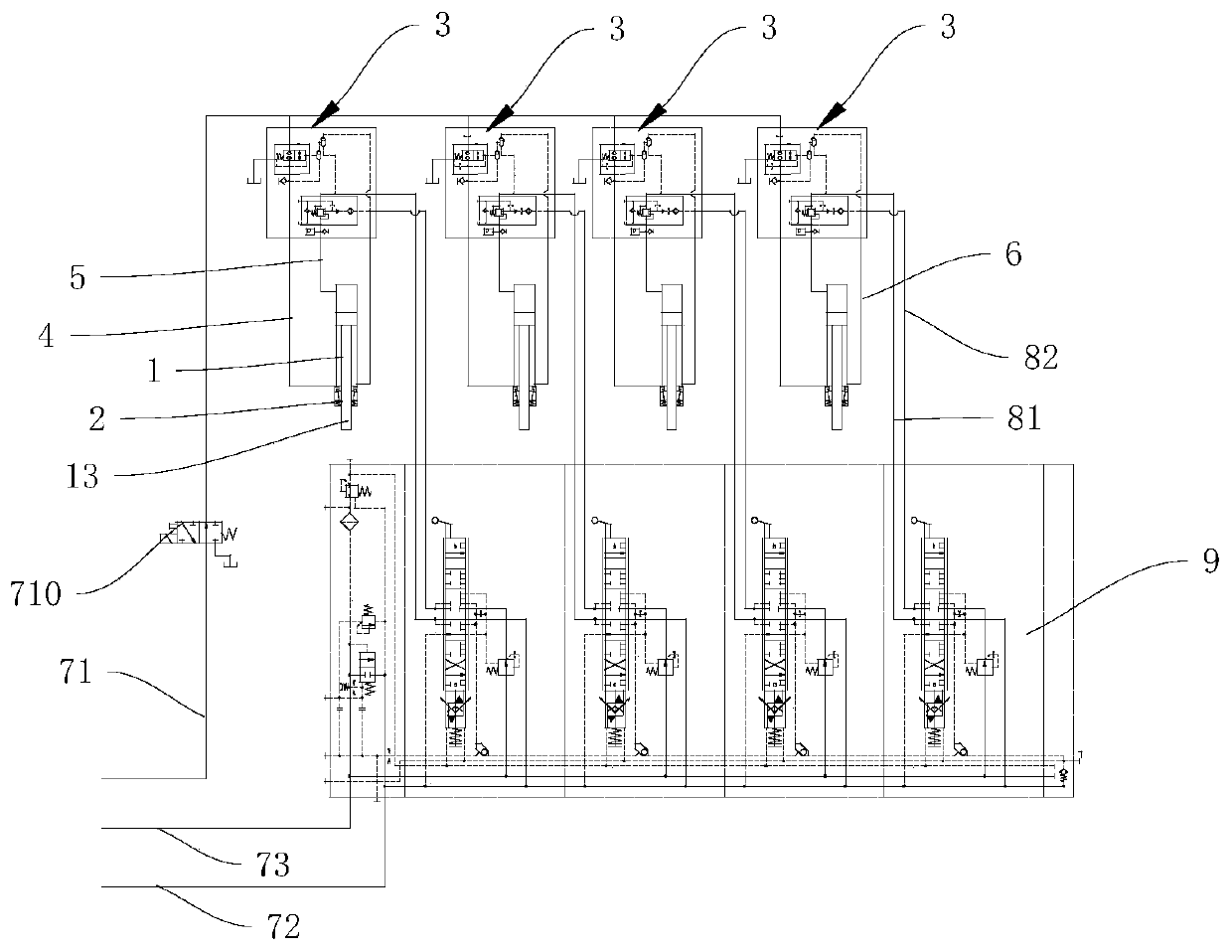

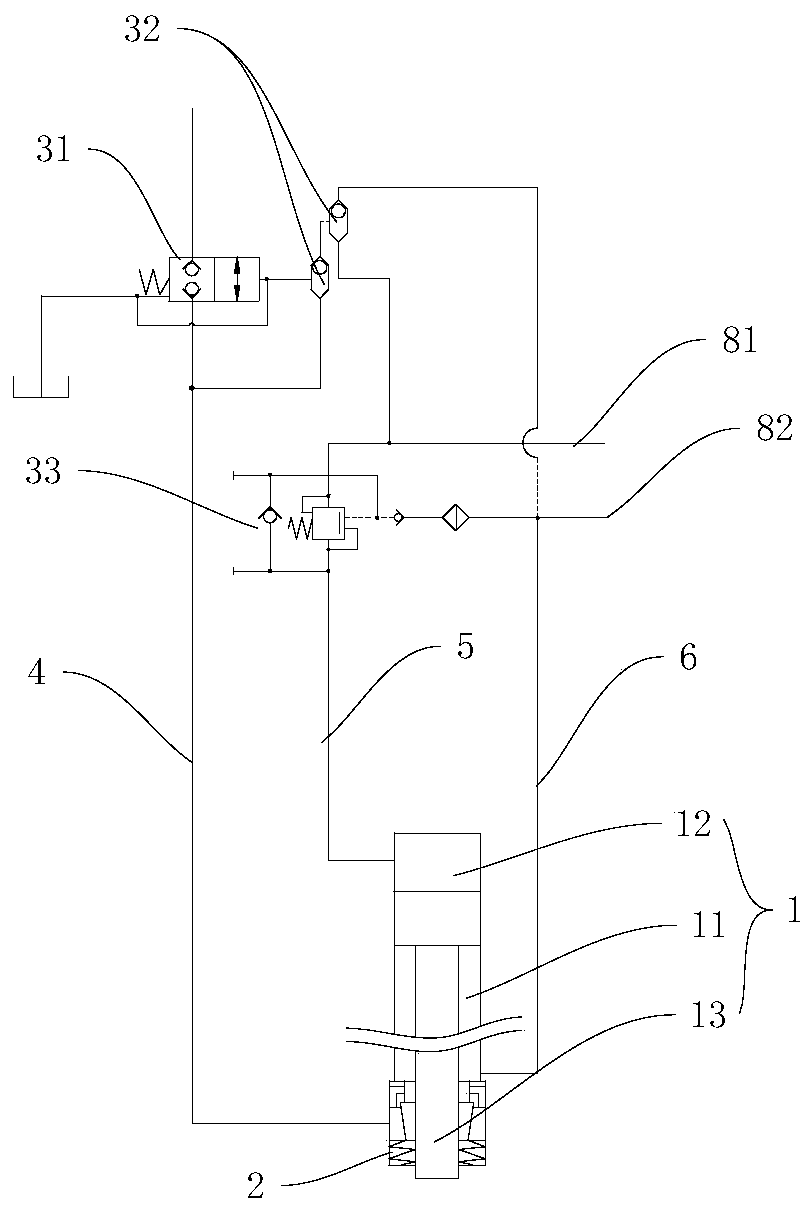

[0044] see Figure 1~2As shown, the embodiment of the present invention provides a leveling control circuit based on hydraulic control self-locking. The leveling control circuit is applied to leveling the hydraulic cylinder 1. The hydraulic cylinder 1 includes a rod chamber 11, a rodless Cavity 12 and hydraulic cylinder rod 13; the leveling control circuit includes a self-locking leveling circuit and a control circuit; the self-locking leveling circuit includes a hydraulic control self-locking valve block 3, a first executive oil circuit 4, a second executive The oil circuit 5, the third executive oil circuit 6 and the mechanical self-locking part 2; the hydraulic control self-locking valve block 3, the first executive oil circuit 4, and the mechanical self-locking part 2 are connected in sequence to limit the hydraulic cylinder rod 13 The movement of the hydraulically controlled self-locking valve block 3, the second executive oil circuit 5, and the rodless cavity 12 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com