Wall screeding equipment for building decoration

A wall and building technology, applied in construction, building structure, cement mixing device, etc., can solve the problems of uneven plastering, device shaking, soiling of artificial clothes, etc., so as to avoid splashing on clothes and avoid precipitation of raw materials. , to avoid the effect of device shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

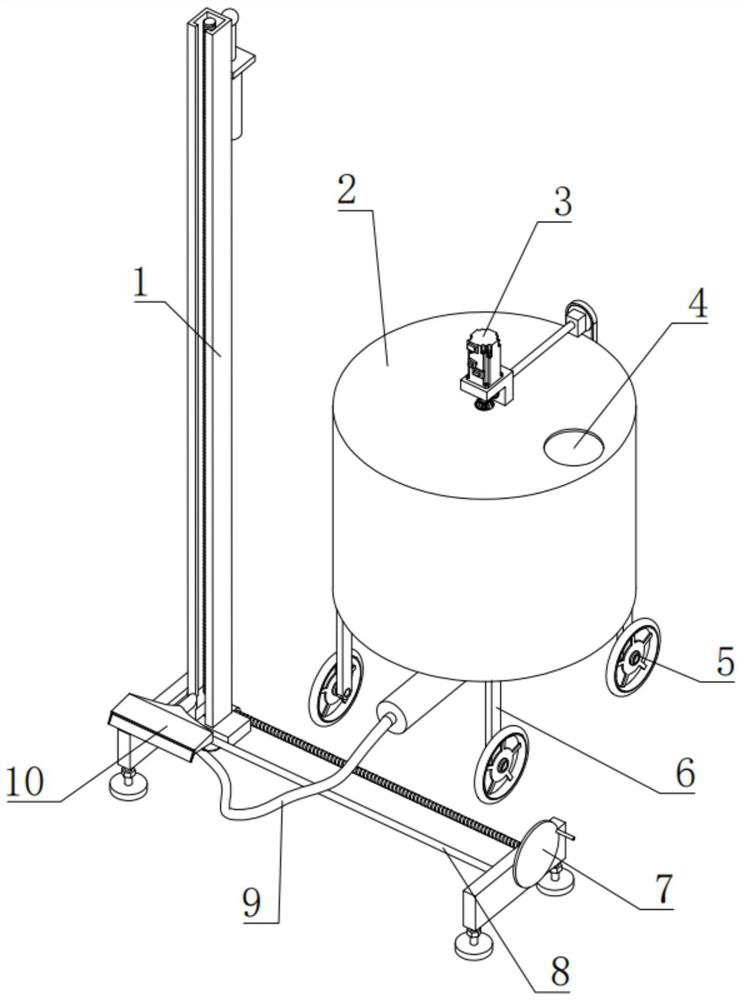

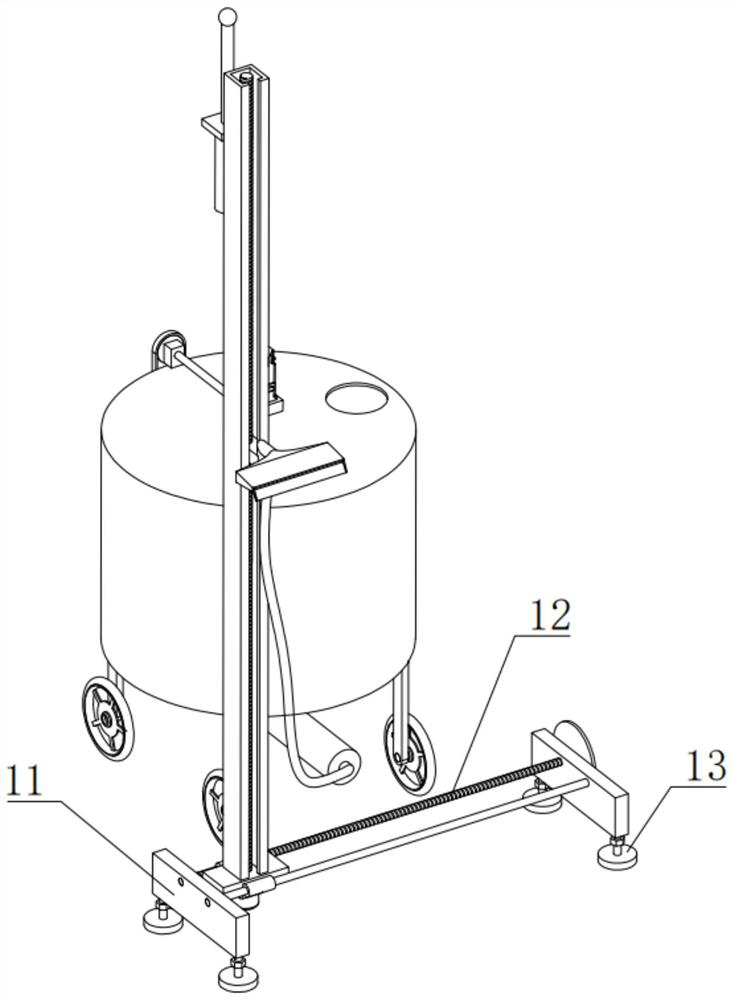

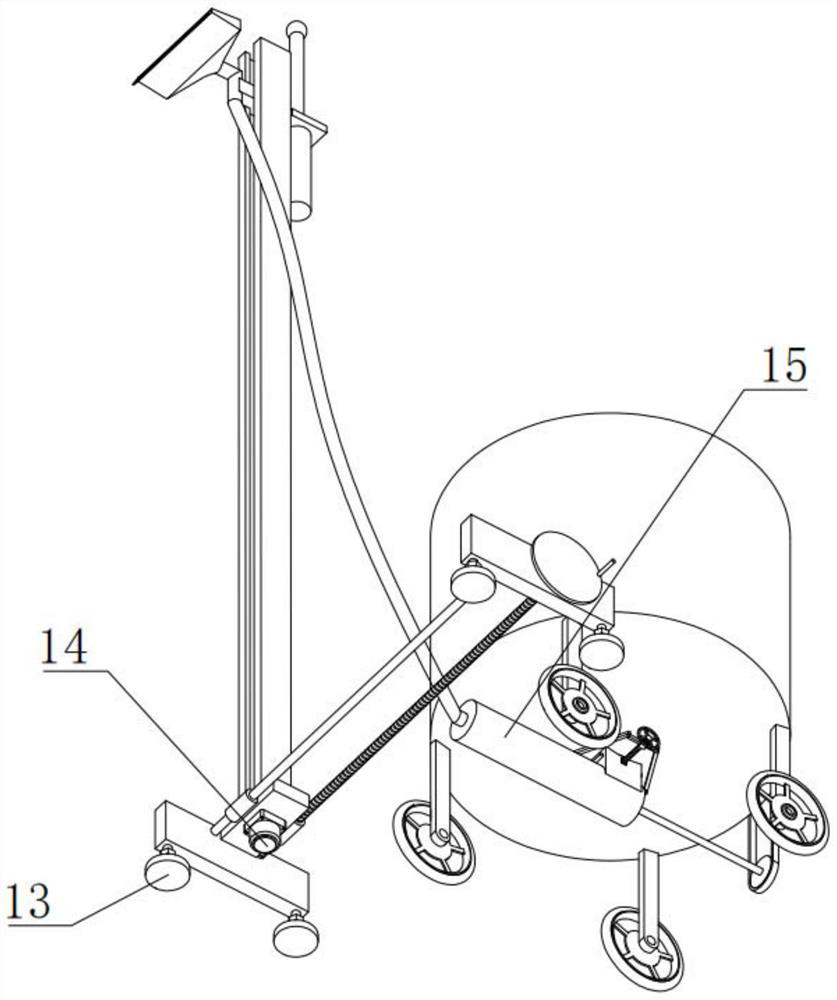

[0043] like Figure 1-Figure 17 As shown, the present invention includes a box body 2, the upper side of the box body 2 is eccentrically provided with a feeding port 4, the lower end of the box body 2 is fixedly connected to the upper side of the box body 27, and the lower side of the box body 27 is fixed with a communication pipe One end of the upper side of the body 15;

[0044] The upper side of the box body 2 is fixedly connected to the lower side of the vertical plate of the L-shaped plate 30, one end of the upper side of the box body 2 is fixedly connected to the lower side of the mounting block 28, and the inner upper side of the box body 2 is fixedly connected to the upper side of the gear ring 36;

[0045] Correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com