Standard colorimetric paper for plant petals/leaves

A technology of plant petals and colorimetric paper, which is applied to non-woody plant/crop pulp, paper, papermaking, etc., can solve the problem that long fibers cannot be effectively used to improve paper strength, short fiber adsorption force cannot be fully exerted, and there is no pulp Separation treatment and other problems, to achieve the effect of strong binding force, improved strength, and improved hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

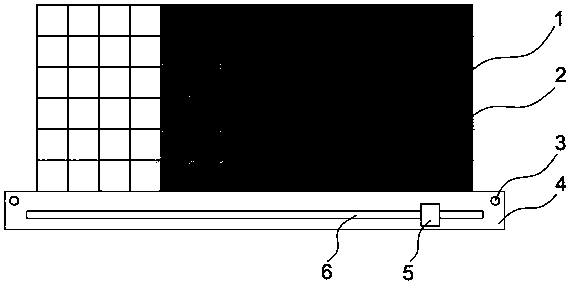

[0035] Plant petal / leaf standard color comparison paper, including short fibers less than or equal to 180 microns and long fibers with a length greater than or equal to 180 microns, the width of the long and short fibers is 4.2-6.5 microns; the tightness of the color comparison paper is 0.618~0.632g· cm -3 , the tear index is 4.92-5.08mN m 2 g -1 . By limiting the length and width of the long and short fibers in the prepared colorimetric paper, the present invention can give full play to the effect of the long fibers, that is, the short fibers can absorb more fillers to improve the retention rate of the fillers, and the long fibers can improve the strength of the colorimetric paper. , and by setting the value of the long and short fibers above, it is beneficial to improve the hydrophobicity of the paper, and the final tightness of the paper is 0.618~0.632g·cm -3 , the tear index is 4.92-5.08mN m 2 g -1 The paper has excellent appearance quality, high physical index, color...

Embodiment 2

[0037] The preparation technology of plant petal / blade standard color comparison paper comprises the following steps:

[0038] 1) Preparation of pulp raw materials:

[0039] a. Material preparation: dry the corn stalks, separate the husks to get the husks, and cut the husks into pieces;

[0040] b. Pretreatment: cook the straw in the cooker, the solid-to-liquid ratio is 1:4, and heat the cooking additives. The cooking time is 2.5 hours. The heating time during the cooking process is 75 minutes. ℃ small outgassing, additives are NaOH and C 14 h 8 o 2 、C 19 h 17 N 3O 、H 2 o 2 Composition, the amount of NaOH is 10.4% of the weight of the cooking liquid used for cooking, C 14 h 8 o 2 The dosage is 1.04% of the weight of straw used for cooking, C 19 h 17 N 3O The dosage is 0.04% of the weight of straw used for cooking, H 2 o 2 The dosage is 2% of the weight of straw used for cooking. During the cooking process, the additives can promote the rapid degradation of the...

Embodiment 3

[0050] Embodiment 3: the preparation technology of plant petal / blade standard color comparison paper comprises following preferred steps:

[0051] 1) Preparation of pulp raw materials:

[0052] a. Material preparation: dry the corn stalks, separate the husks to get the husks, and cut the husks into pieces;

[0053] b. Pretreatment: cook the straw in a cooker with a solid-to-liquid ratio of 1:6, and heat the cooking additives for 3 hours. During the cooking process, the heating time is 80 minutes. Small outgassing, the additive consists of NaOH and C 14 h 8 o 2 、C 19 h 17 N 3O 、H 2 o 2 Composition, the amount of NaOH is 12% of the weight of the cooking liquid used for cooking, C 14 h 8 o 2 The dosage is 1.08% of the weight of straw used for cooking, C 19 h 17 N 3O The dosage is 0.05% of the weight of straw used for cooking, H 2 o 2 The dosage is 2% of the weight of straw used for cooking;

[0054] c. Bleaching and cleaning: the straw pulp is bleached by CHE thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com