A transformation system suitable for various corrugated cardboard production lines

A corrugated cardboard and production line technology, which is applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of loss of customers, collapse of boxes, and dampness of cardboard boxes, and achieve high secondary utilization rate, improved service life, and good moisture-proof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

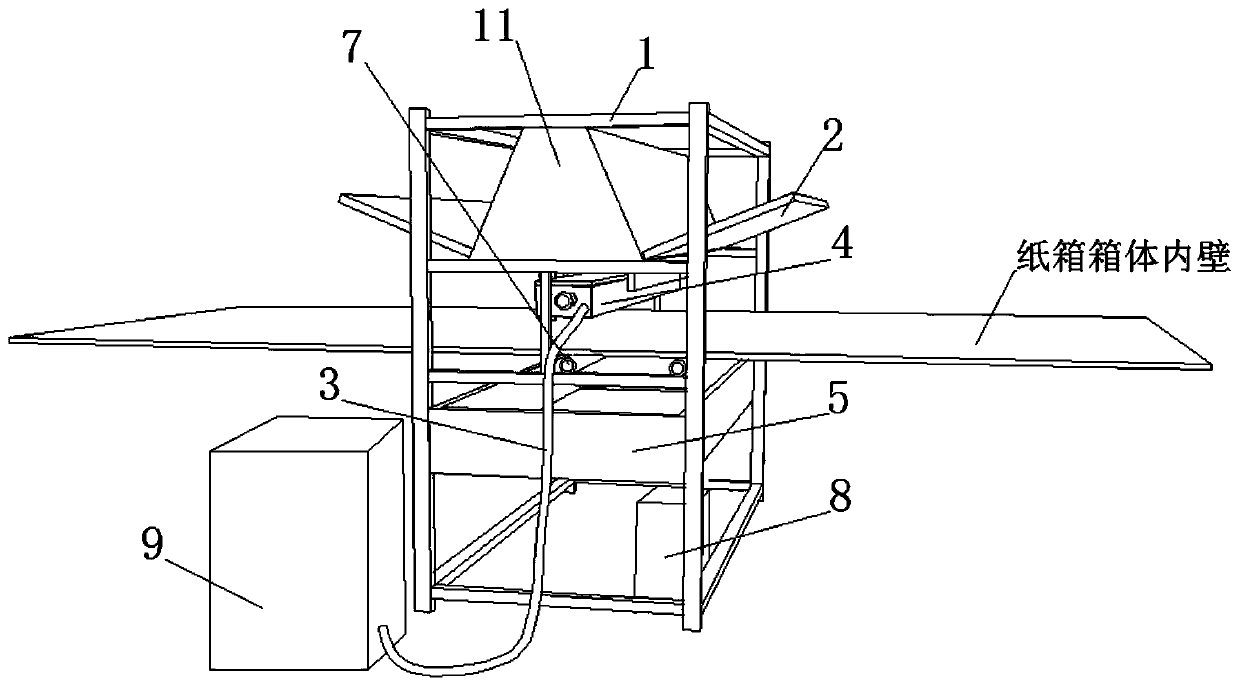

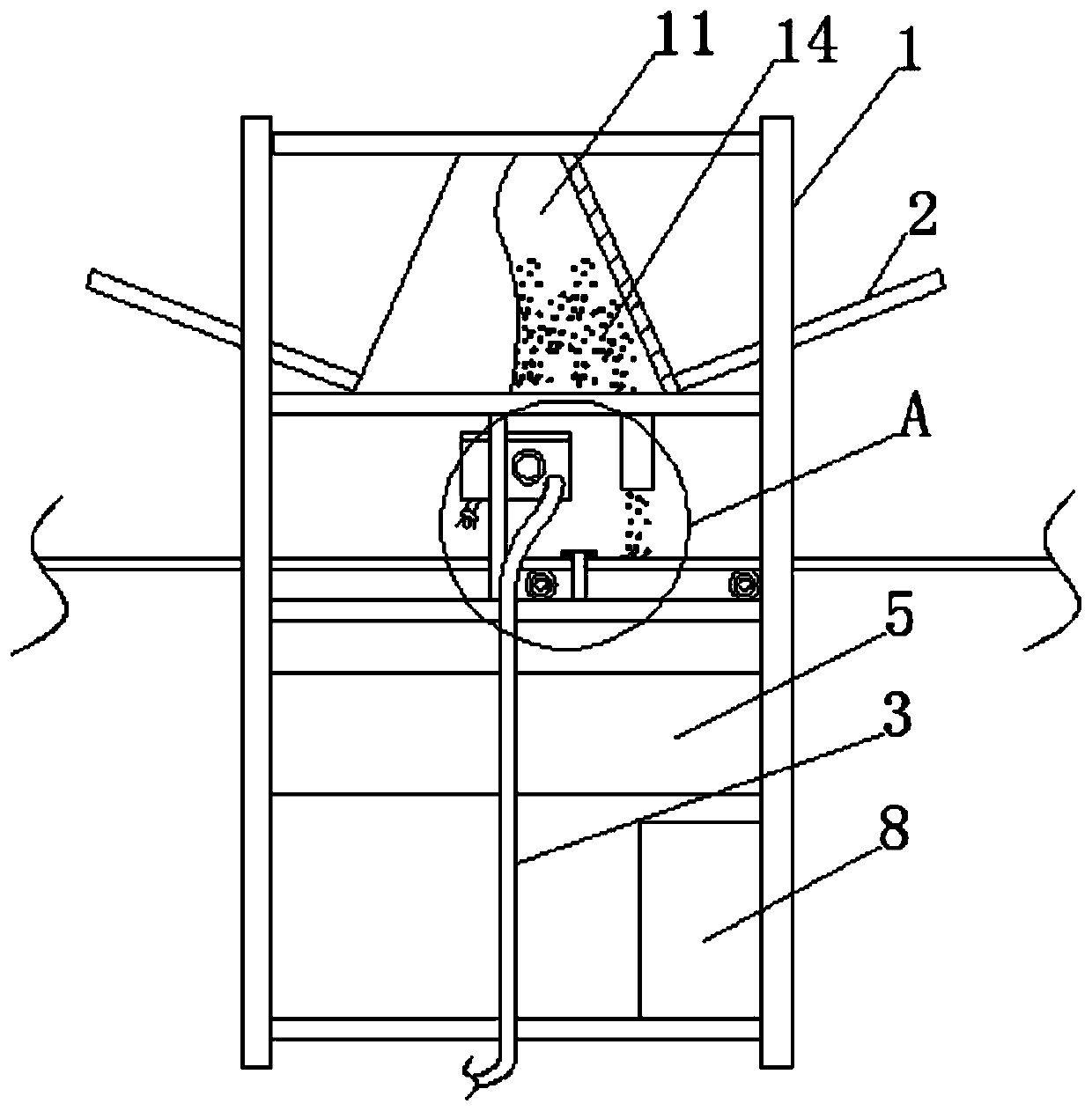

[0049] see figure 1 , a system applicable to various corrugated cardboard production lines, including a corrugated cardboard box production line, and equipment for spraying waterproof oil on the end face of the corrugated cardboard used to manufacture the cardboard box, the end face of the corrugated cardboard being the inner wall of the carton.

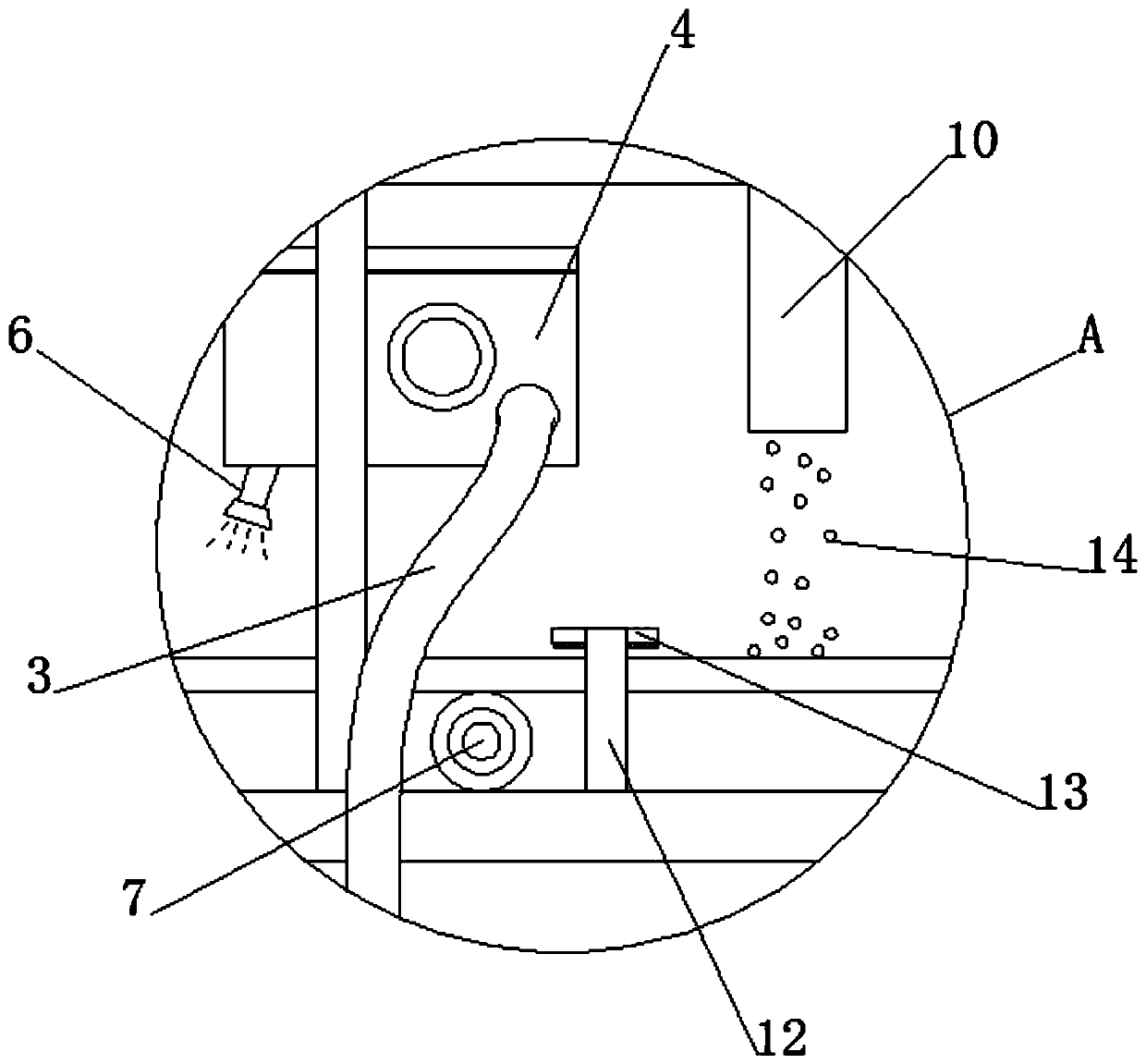

[0050] The waterproof oil spraying equipment includes a frame body 1 and an oil tank 9, the fuel tank 9 is located on the left side of the frame body 1, the control cabinet 8 is installed at the lower end of the frame body 1, the spray box 4 is installed at the upper end of the frame body 1, and the outer end of the spray box 4 is connected with a pipeline 3 , the outer end of the pipeline 3 is connected with a solenoid valve, the end of the pipeline 3 away from the spray box 4 is connected with the fuel tank 9, the left and right ends of the frame body 1 are connected with the cover 2 through the stop hinge, and can be turned down wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com