Corrosion-resistant and anti-blocking drainage pipe and preparation method thereof

A drainage pipe and corrosion-resistant technology, applied in antifouling/underwater coatings, anti-corrosion coatings, paints containing biocides, etc., can solve problems such as difficult replacement or cleaning of pipes, easy breeding of bacteria in pipes, and impact on water quality, etc., to achieve Effects of preventing clogging, enhancing stability, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A corrosion-resistant and anti-blocking drainage pipe, comprising a plastic pipe, a self-cleaning layer, and a corrosion-resistant layer, the corrosion-resistant layer is evenly sprayed on the inner wall of the plastic pipe, and the self-cleaning layer is evenly sprayed on the corrosion-resistant The surface of the layer; the self-cleaning layer includes the following raw materials in parts by weight: nano-silver 1kg, glass powder 1kg, polystyrene 3kg, polydimethylsiloxane 5kg; the corrosion-resistant layer includes the following parts by weight Raw materials: 10kg of polytetrafluoroethylene, 5kg of carbon fiber, 5kg of bisphenol A epoxy resin, 1kg of additive, 7kg of turpentine, and 1kg of compatibilizer.

[0034] The preparation method of the anti-corrosion and anti-blocking drainage pipeline comprises the following steps:

[0035] (1) prepare self-cleaning coating, standby;

[0036] (2) prepare corrosion-resistant coating, standby;

[0037] (3) Corrosion-resistant ...

Embodiment 2

[0047] A corrosion-resistant and anti-blocking drainage pipe, comprising a plastic pipe, a self-cleaning layer, and a corrosion-resistant layer, the corrosion-resistant layer is evenly sprayed on the inner wall of the plastic pipe, and the self-cleaning layer is evenly sprayed on the corrosion-resistant The surface of the layer; the self-cleaning layer includes the following raw materials in parts by weight: nano-silver 2kg, glass powder 1kg, polystyrene 5kg, polydimethylsiloxane 8kg; the corrosion-resistant layer includes the following parts by weight Raw materials: 12kg of polytetrafluoroethylene, 10kg of carbon fiber, 6kg of bisphenol A epoxy resin, 2kg of talcum powder, 8kg of turpentine, and 2kg of maleic anhydride.

[0048] The preparation method of the anti-corrosion and anti-blocking drainage pipeline comprises the following steps:

[0049] (1) Prepare the self-cleaning coating, mix and stir the raw materials of the self-cleaning layer at a temperature of 10° C. at a h...

Embodiment 3

[0060] A corrosion-resistant and anti-blocking drainage pipe, comprising a plastic pipe, a self-cleaning layer, and a corrosion-resistant layer, the corrosion-resistant layer is evenly sprayed on the inner wall of the plastic pipe, and the self-cleaning layer is evenly sprayed on the corrosion-resistant The surface of the layer; the self-cleaning layer includes the following raw materials in parts by weight: nano-silver 3kg, glass powder 1.5kg, polystyrene 6kg, polydimethylsiloxane 10kg; the corrosion-resistant layer includes the following parts by weight Raw materials: 12kg of polytetrafluoroethylene, 15kg of carbon fiber, 8kg of bisphenol A epoxy resin, 2kg of a mixture of equal mass of talcum powder and organic bentonite, 10kg of turpentine, and 4kg of maleic anhydride.

[0061] The preparation method of the anti-corrosion and anti-blocking drainage pipeline comprises the following steps:

[0062] (1) To prepare the self-cleaning coating, mix and stir the raw materials of t...

PUM

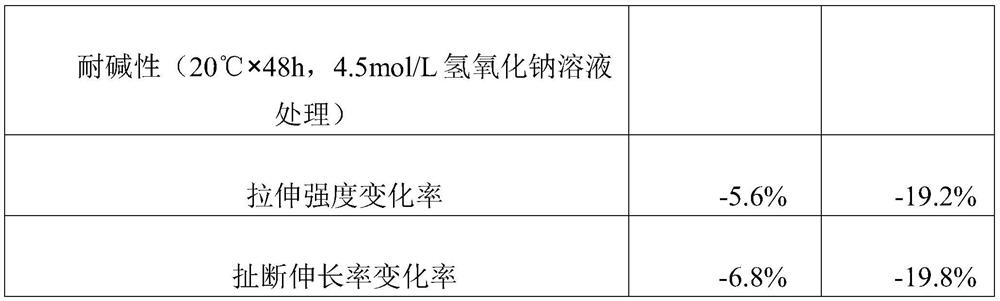

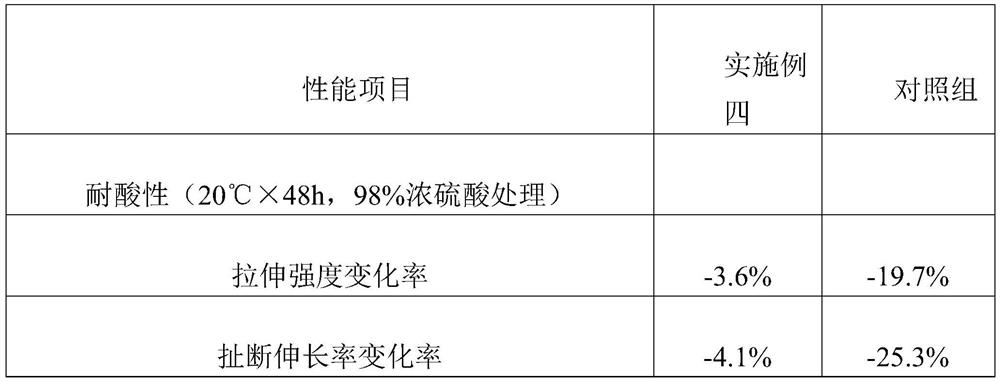

| Property | Measurement | Unit |

|---|---|---|

| rate of change | aaaaa | aaaaa |

| rate of change of tensile strength | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com