Low-temperature curing method of perfluoropolyether antifouling film

A technology of perfluoropolyether and curing method, used in polyether coatings, antifouling/underwater coatings, and biocide-containing paints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

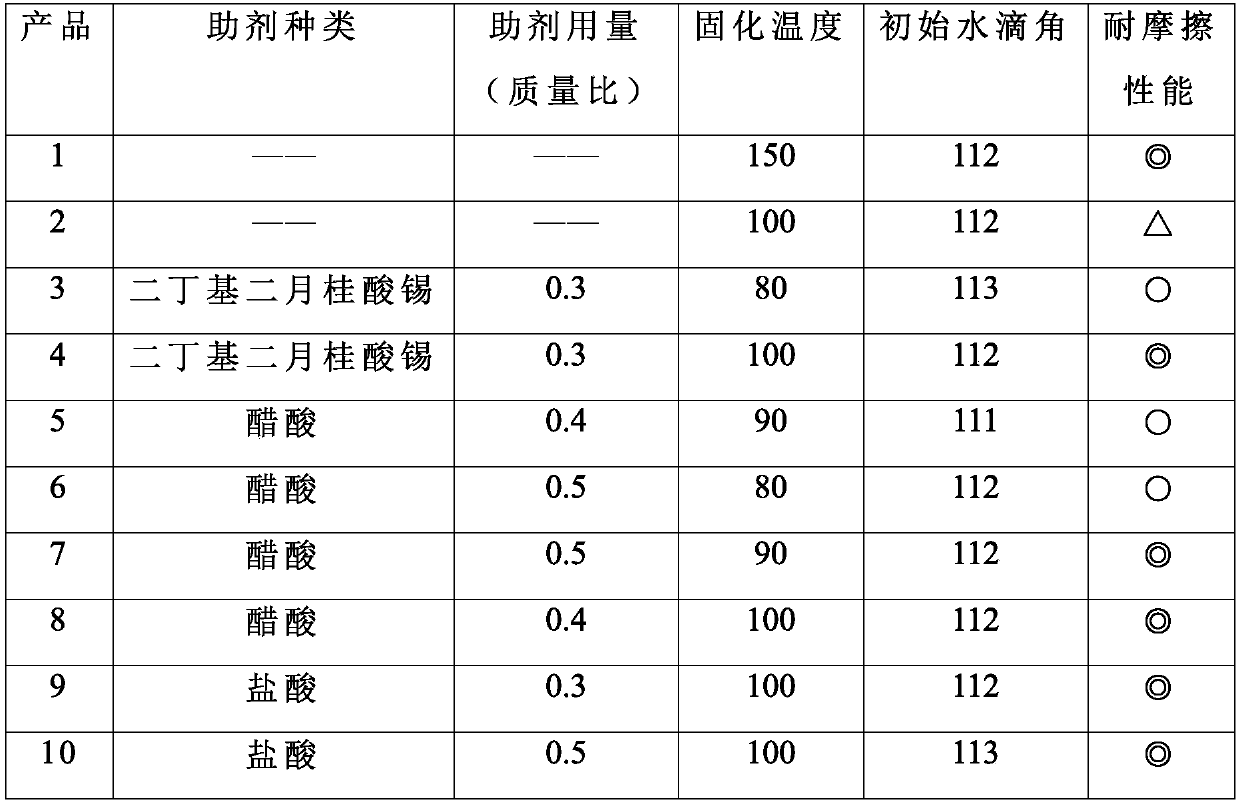

[0016] The anti-fingerprint agent UD509 of Daikin Company of Japan was prepared into a coating solution with a concentration of 3‰ with 3M hydrofluoroether 7200, and different reaction additives were added, as shown in Table 1. The coating experiment was carried out with the above coating solution by spraying process, and cured at different curing temperatures for 0.5h, and the corresponding friction resistance was tested. The results are shown in Table 1.

[0017] For the evaluation of friction resistance, use 0000# steel wool to perform reciprocating mechanical friction on the glass surface, add 1kg / cm 2 The load, the friction frequency is 60 times / min, and the reciprocating friction is 4000 times. After rubbing 4000 times, if the water drop angle > 105°, the friction resistance level is excellent, represented by ◎; if the water drop angle is 101-105°, the friction resistance level is average, represented by ○; if the water drop angle is <100°, then The grade of friction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com