Multiple-functional-layer drying and curing device

A curing equipment, multi-functional technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of low finished product efficiency, poor heat utilization, unreasonable layout, etc., to improve utilization, save energy, Thorough drying and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

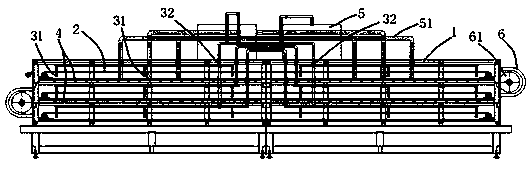

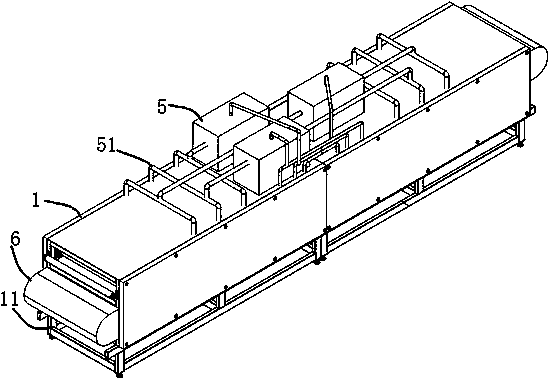

[0015] A multi-functional layer drying and curing equipment, combined with figure 1 with figure 2 As shown, it includes a box body 1, and several layers of conveyor belts 2 are arranged in the box body 1, and each layer of conveyor belts 2 is respectively located in the heat-insulating cavity corresponding to it in the box body 1. There are several hot gas discharge ports 31 distributed below the conveyor belt 2 in the heat insulation chamber, and several hot gas recovery ports 32 are distributed above the conveyor belt 2 in the heat insulation chamber. The conveyor belt 2 It is a breathable structure, the hot gas di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com