Heatable drum-type aerobic compost reactor

An aerobic composting and reactor technology, which is applied in the heating/cooling, application, organic fertilizer and other directions of chemical fertilizer treatment, can solve the problems of difficult mixing and mixing of compost, poor mass and heat transfer, etc., so as to reduce management and maintenance costs and operating costs. The effect of low operating costs and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

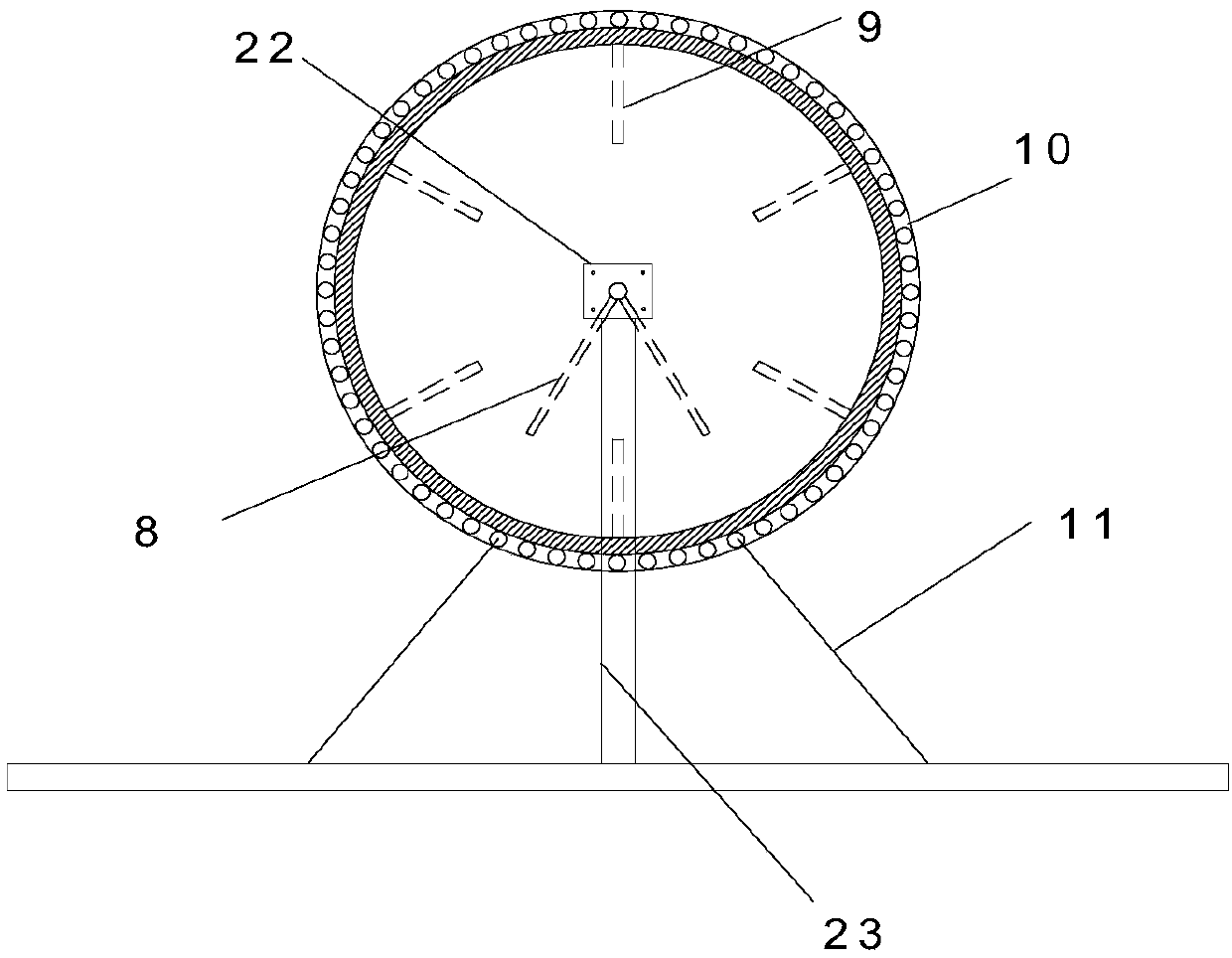

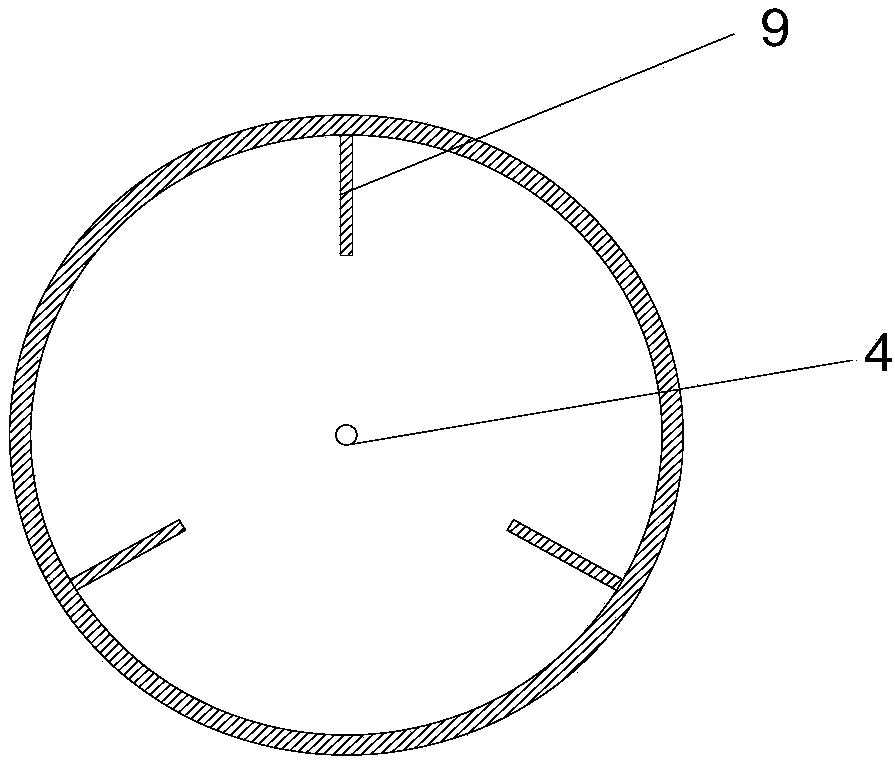

[0026] like Figure 1 to Figure 5 As shown, a heatable drum type aerobic composting reactor of the present invention comprises a horizontally arranged cylindrical body 1, the cylindrical body 1 is made of stainless steel or plexiglass, the diameter of the cylindrical body is 300 cm, the length is 500 cm, the wall thickness is 10 cm, and the cylindrical body 1 is 1. There is a layer of insulation layer 7 on the outer side, and the material of the insulation layer 7 is polystyrene or foamed asbestos to ensure that the temperature in the cylinder body 1 meets the requirements; the cylinder wall of the cylinder body 1 is provided with a feed port 2 and a discharge port 3 , the feed port 2 and the discharge port 3 are close to the two ends of the cylinder 1, the feed port 2 and the discharge port 3 are symmetrically distributed in the center of the cylinder body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com