Method for comprehensively recycling mixed secondary aluminum dross

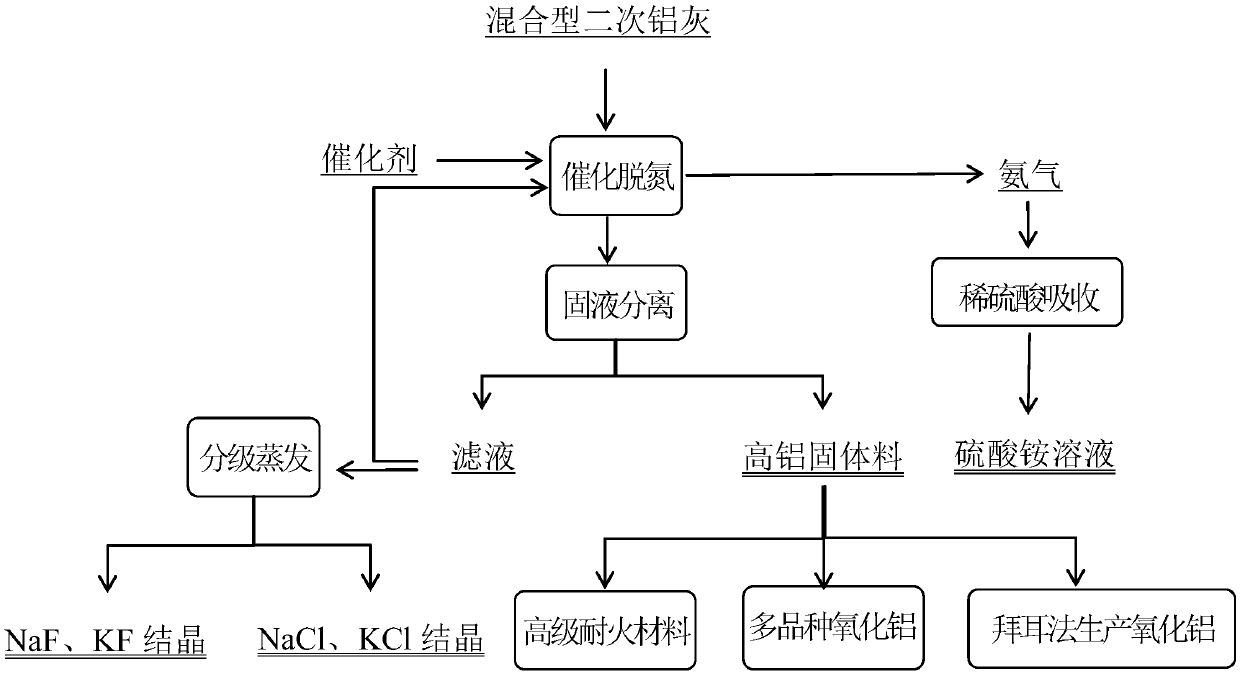

A secondary aluminum and mixed technology, applied in chemical instruments and methods, ammonia compounds, alkali metal chlorides, etc., can solve the problems of unconsidered treatment and recycling, low recovery rate, insufficient decomposition of aluminum nitride, etc. , to achieve the effect of green recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for recycling multiple elements of mixed secondary aluminum ash, comprising the following steps:

[0034] a) Catalytic deamination step: the mixed secondary aluminum ash is placed in a closed container, and water and 4wt% NaF are added thereto as a catalyst at 95°C under stirring conditions to form a mixture, and the liquid-solid ratio is controlled to be 6, and the reaction After leaching for 8 hours, after the reaction is completed, the solid-liquid separation will obtain the filtrate and high-alumina solid material, and the high-alumina solid material will be directly returned to the Bayer processing system for the production of alumina products;

[0035] b) Ammonia gas recovery step: In the above-mentioned catalytic deamination step, aluminum nitride in the secondary aluminum ash is completely decomposed to generate ammonia gas under high temperature conditions, and the released ammonia gas is passed into the recovery device, and the concentration of sprayin...

Embodiment 2

[0039] A method for recycling multiple elements of mixed secondary aluminum ash, comprising the following steps:

[0040] a) Catalytic deamination step: place the mixed secondary aluminum ash in a closed container, add water and 3wt% NaF and KF mixture thereinto as a catalyst at 90°C under stirring conditions to form a mixture, and control the liquid-solid ratio to 8. Reaction and leaching for 6 hours. After the reaction is completed, solid-liquid separation is obtained to obtain the filtrate and high-alumina solid material, which is used to produce high-grade refractory materials;

[0041] b) Ammonia gas recovery step: In the above-mentioned catalytic deamination step, aluminum nitride in the secondary aluminum ash is completely decomposed to generate ammonia gas under high temperature conditions, and the released ammonia gas is passed into the recovery device, and the concentration of spraying in the recovery device is 0.5% dilute sulfuric acid collects the escaping ammonia ...

Embodiment 3

[0045] A method for recycling multiple elements of mixed secondary aluminum ash, comprising the following steps:

[0046] a) Catalytic deamination step: place the mixed secondary aluminum ash in a closed container, add water and 2wt% AlF as a catalyst at 80°C under stirring conditions to form a mixture, control the liquid-solid ratio to 5, and react Leach for 10 hours, and after the reaction is completed, the solid-liquid separation is obtained to obtain the filtrate and high-alumina solid material, which is used to produce various alumina products;

[0047] b) Ammonia gas recovery step: in the above-mentioned catalytic deamination step, aluminum nitride in the secondary aluminum ash is completely decomposed to generate ammonia gas under high temperature conditions, and the released ammonia gas is passed into the recovery device, and the concentration of spraying in the recovery device is 0.8% dilute sulfuric acid collects the escaping ammonia gas to obtain an ammonium sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com