PE mulching film

A mulch and the outermost layer technology, applied in plant protection, application, gardening, etc., can solve the problems of affecting the light transmittance and warming effect of the mulch, the accumulation of dust on the surface of the PE mulch, and the reduction of the sunlight transmittance of the mulch, etc., to achieve Increase light transmittance, good warming effect, and beneficial to increase production and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] PE film of the present invention can be prepared by following method, and its preparation method comprises:

[0028] (1) Extrusion: Mix the raw materials of the outermost layer, the second outer layer, the middle layer, the second inner layer and the innermost layer according to the ratio, and send them to the extruder of the five-layer co-extrusion film blowing unit;

[0029] (2) Blown film: the PE film is made by blowing the extruder of the five-layer co-extruded film blowing unit once;

[0030] (3) cooling;

[0031] (4) traction;

[0032] (5) coiling.

[0033] The PE film of the present invention will be described in detail through specific examples below, but the implementation scope of the present invention is not limited thereto.

Embodiment 1

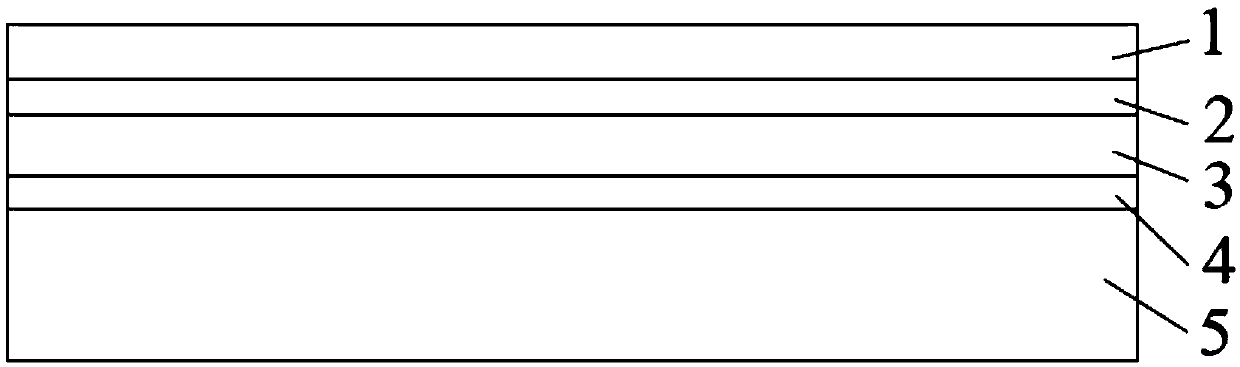

[0035] The PE film includes the outermost layer, the second outer layer, the middle layer, the second inner layer and the innermost layer from top to bottom. The total thickness of the PE film is 30um. The performance parameters of each layer are as follows.

[0036] Outermost layer: 5% rigid amidopropyl dimethyl-β-hydroxyethyl ammonium nitrate and 95% LLDPE, the thickness is 1% of the total thickness of the PE film;

[0037] Second outer layer: the density of the material is 0.920g / cm 3 , the melt index is 1.0g / 10min, the thickness is 15% of the total thickness of the PE film, and the material density is 0.940g / cm 3 mPE and density of 0.910g / cm 3 The mLLDPE composition;

[0038] Middle layer: material with a density of 0.930g / cm 3 HDPE, the thickness is 30% of the total thickness of PE film;

[0039] Sub-inner layer: The density of the material is 0.920g / cm 3 , the melt index is 1.0g / 10min, the thickness is 15% of the total thickness of the PE film, and the material dens...

Embodiment 2

[0042] The PE film includes the outermost layer, the second outer layer, the middle layer, the second inner layer and the innermost layer from top to bottom. The total thickness of the PE film is 30um. The performance parameters of each layer are as follows.

[0043] Outermost layer: 15% (3-lauric acid aminopropyl) trimethylammonium methyl sulfate and 85% LLDPE, the thickness is 10% of the total thickness of the PE film;

[0044] Second outer layer: the density of the material is 0.920g / cm 3 , the melt index is 1.0g / 10min, the thickness is 15% of the total thickness of the PE film, and the material density is 0.970g / cm 3 mPE and density of 0.910g / cm 3 The mLLDPE composition;

[0045] Middle layer: material with a density of 0.950g / cm 3 HDPE, the thickness is 30% of the total thickness of PE film;

[0046] Sub-inner layer: The density of the material is 0.920g / cm 3, the melt index is 1.0g / 10min, the thickness is 15% of the total thickness of the PE film, and the material d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com